Dry process stack gas desulfur reaction tower with variation structure

A technology of dry flue gas desulfurization and desulfurization tower, which is applied in the field of dry flue gas desulfurization reaction tower, large-scale tower body design, single-tower multi-bed circulation fluidized large-scale dry flue gas desulfurization process, which can solve the problem of particles Separation of problems such as excessive load to achieve the effect of improving particle internal circulation efficiency, strengthening multi-phase mixing and turbulence intensity, and improving desulfurization reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

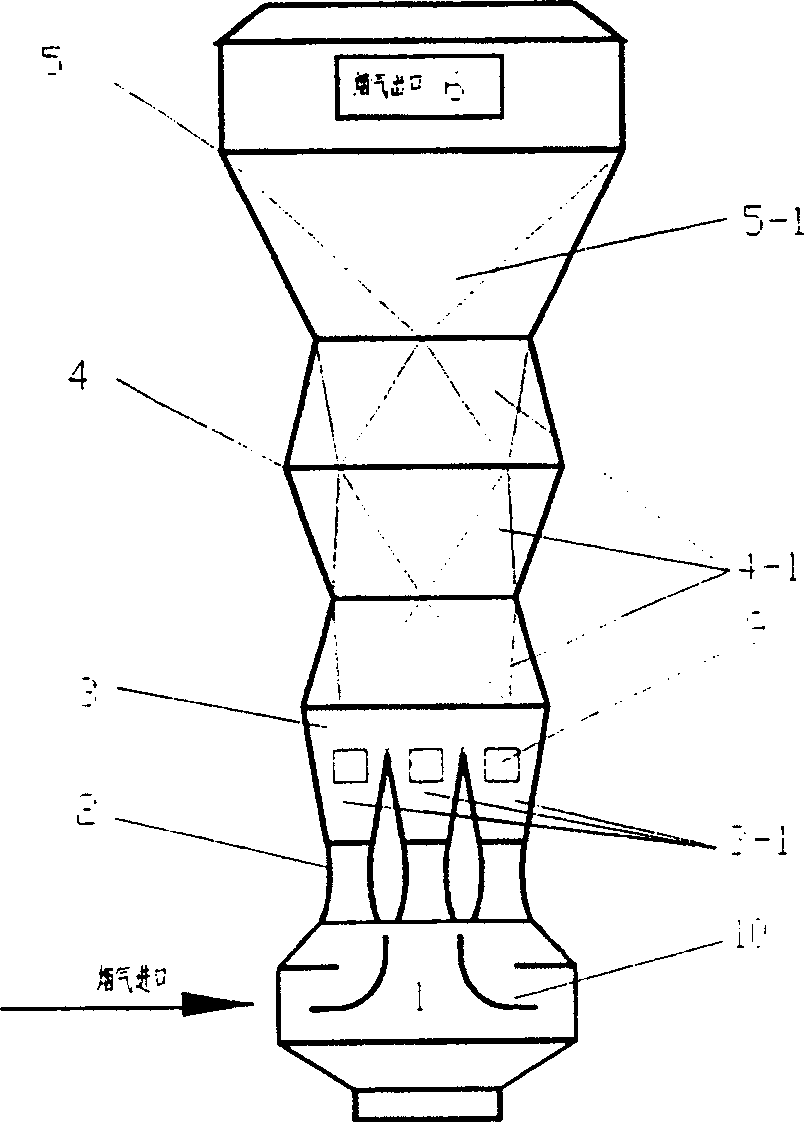

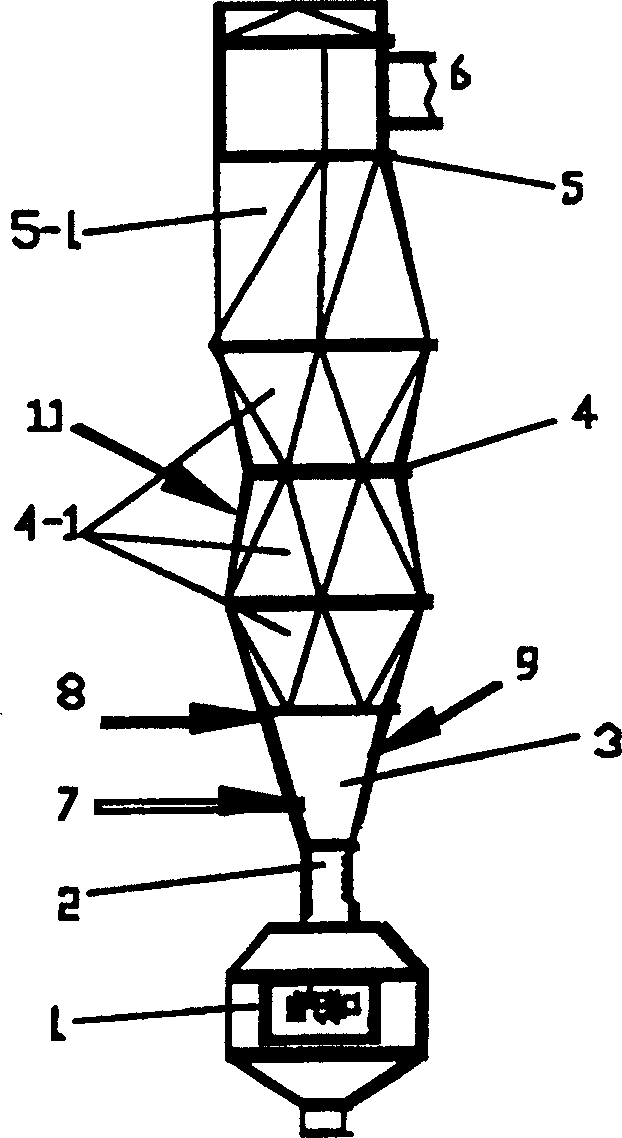

[0032] In the field of dry-process flue gas desulfurization, the present invention proposes the design principle and technical design scheme of the complex variable structure of the desulfurization tower, especially for the single-tower multi-bed fluidization technology adopted in the large-scale dry-process flue gas desulfurization system. On the one hand, through the variable design of the cross-section of each position of the tower body, the fluidized three-phase (flue gas, desulfurizer particles, atomized water particles) can be strongly mixed in each space in the tower, and a high turbulence intensity can be realized to achieve Improve the efficiency of desulfurization reaction, and due to the variation of the cross section of the tower body, the flue gas flow in the tower will form a multi-directional direction, and there will be more recirculation zones in each cross section of the tower, which will greatly improve the internal circulation of desulfurizer particles in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com