Method of prolonging service life of heavy oil and residual oil hydrogenating catalyst

A technology for residual oil hydrogenation and catalyst, which is applied in the direction of physical/chemical process catalysts, catalyst carriers, chemical instruments and methods, etc. It can solve the problems of unstable phase state of liquid phase flow, less overlap of fractions, and aggravated coke, etc., to achieve Strong raw material adaptability, extended operation cycle, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

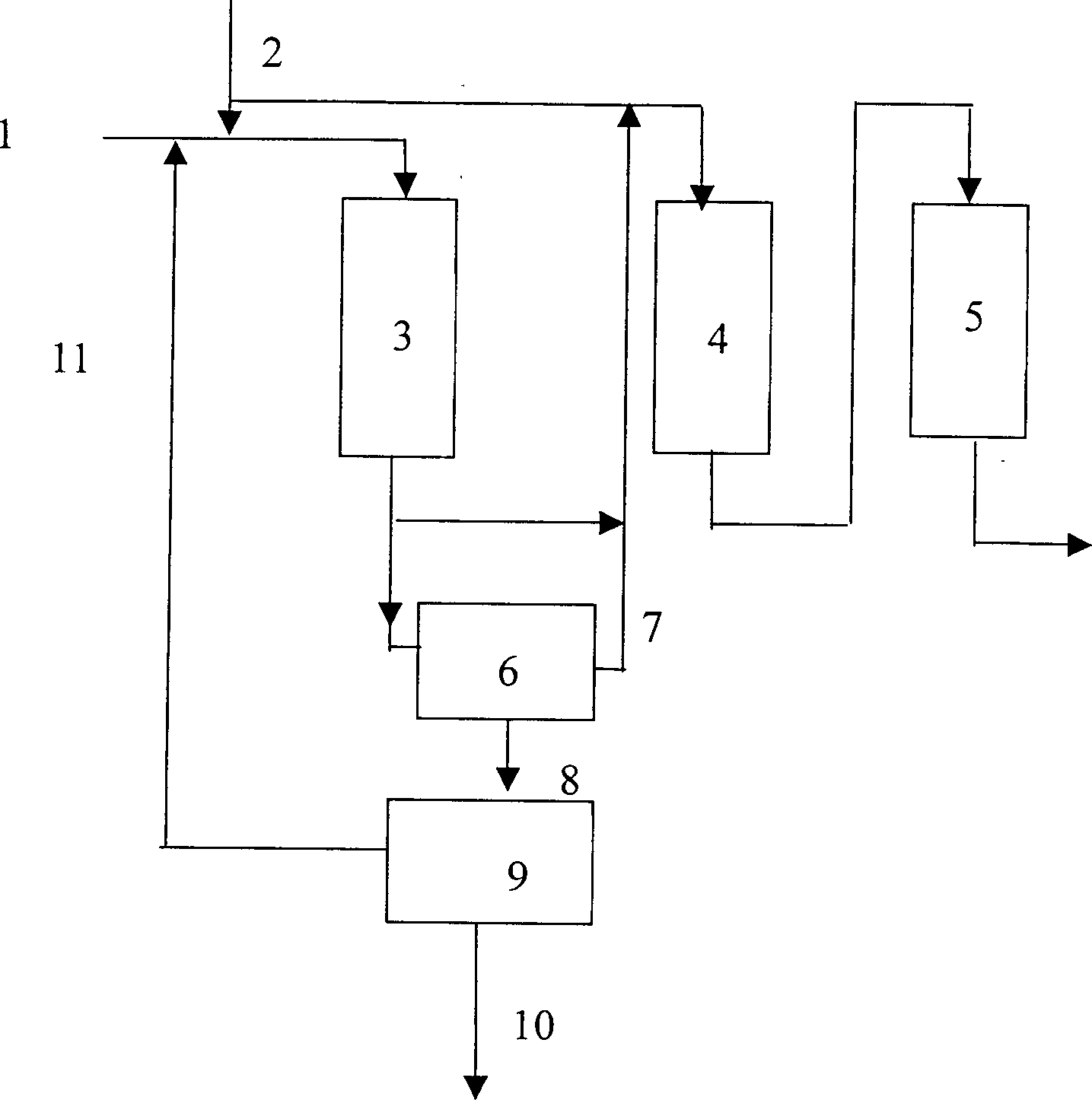

Method used

Image

Examples

Embodiment 1

[0029] On a set of residual oil hydrotreating test device A with three reactors in series, the residual oil hydrotreating test was carried out using a full range of residue hydrotreating catalysts developed by Fushun Petrochemical Research Institute. The loading conditions of each anticatalyst are as follows: the first anti ZTS01 and ZTS02 are loaded from top to bottom, the filling ratio (V) is: 7.5:1, and the three reactors are filled with ZTN01 from top to bottom, and the filling ratio (V) of the three reactors is 45:20:35. The above-mentioned CEN-2, CEN4, FZC-16, CEN-5, and CEN6 catalysts are produced by the pilot base of Fushun Petrochemical Research Institute, and ZTS01, ZTS02, and ZTN01 are produced by the No. 1 Fertilizer Factory of Qilu Petrochemical Company. The main physicochemical properties of the catalysts are listed in Table 1.

[0030] The operating conditions of the residual oil hydrogenation unit are: reaction pressure 15.7MPa, reaction temperature 385°C, hyd...

Embodiment 2

[0043] On a set of residual oil hydrogenation test device B with two reactors in series, the residual oil hydrotreating test was carried out using a full range of residual oil hydrotreating catalysts developed by Fushun Petrochemical Research Institute. The loading conditions of each anti-catalyst are: the first anti-catalyst is filled with CEN-2, CEN4, FZC-16, CEN-5, CEN6 from top to bottom, the filling ratio (V) is: 1:1.5:2.2:2.4:13, the second anti- Fill FZC-301 from top to bottom, and the filling ratio (V) of the two reactors is 50:50. The above-mentioned CEN-2, CEN4, FZC-16, CEN-5, and CEN6 catalysts are produced by the pilot base of Fushun Petrochemical Research Institute, and FZC-301 is produced by the No. 1 Fertilizer Factory of Qilu Petrochemical Company.

[0044] The operating conditions of the residual oil hydrogenation unit are: reaction pressure 14.0MPa, reaction temperature 384°C, hydrogen-oil ratio 650 (v / v), liquid hourly volume space velocity 0.235h -1 (for r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com