Device for low-temperature continuous conversion of potassium chloride to heating steam and production process thereof

A potassium chloride and steam technology, which is applied to potash fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of high investment and maintenance costs, many reactions and auxiliary equipment, and low heat utilization rate, and achieves low investment and maintenance costs. Less reaction and auxiliary equipment, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

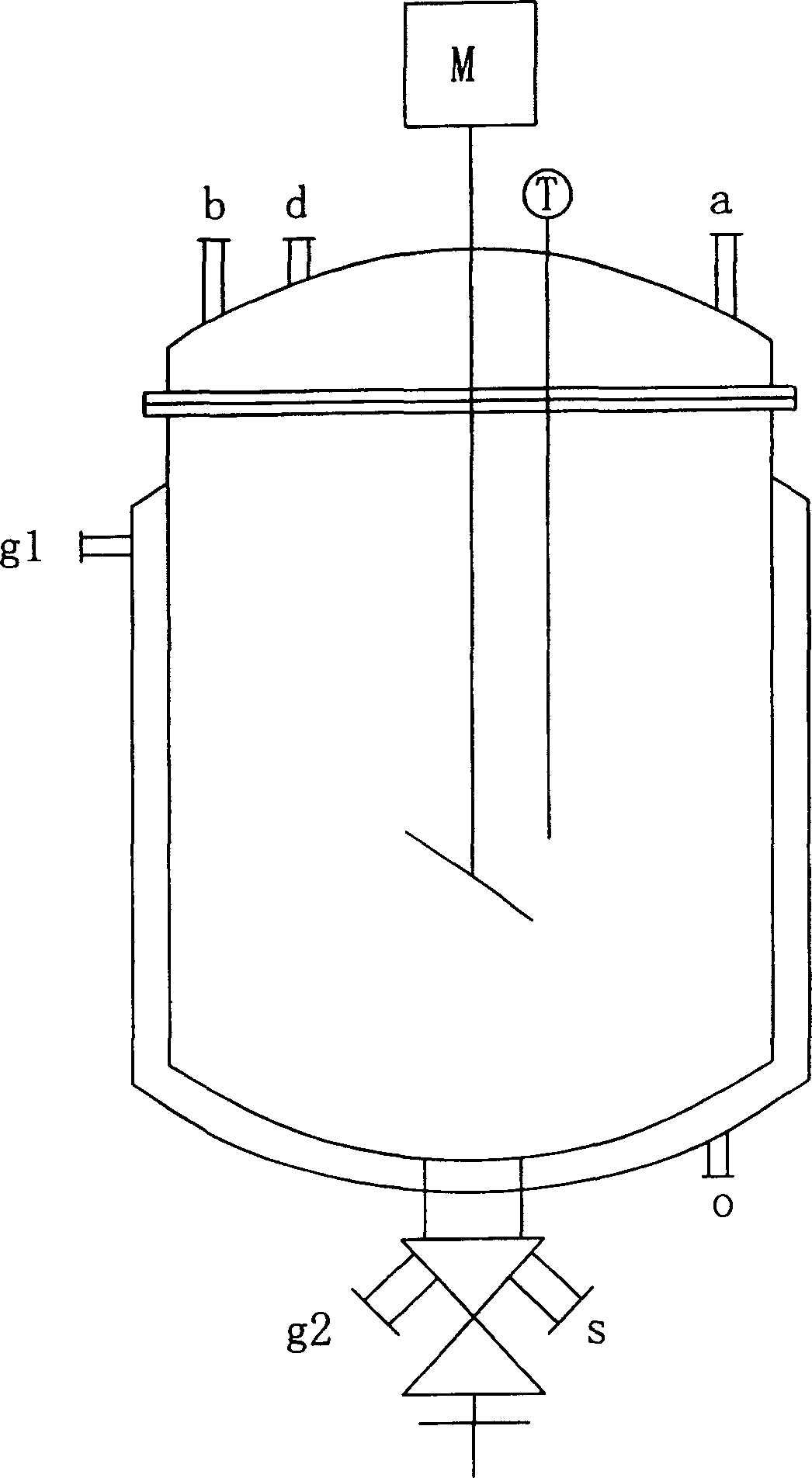

[0025] Such as figure 1 The shown existing equipment is provided with sulfuric acid inlet a, potassium chloride inlet b, hydrogen chloride outlet d, and steam inlet g on the barrel-shaped reactor 1 , g 2 , discharge port s, condensed water outlet o, stirring paddle M, thermometer T.

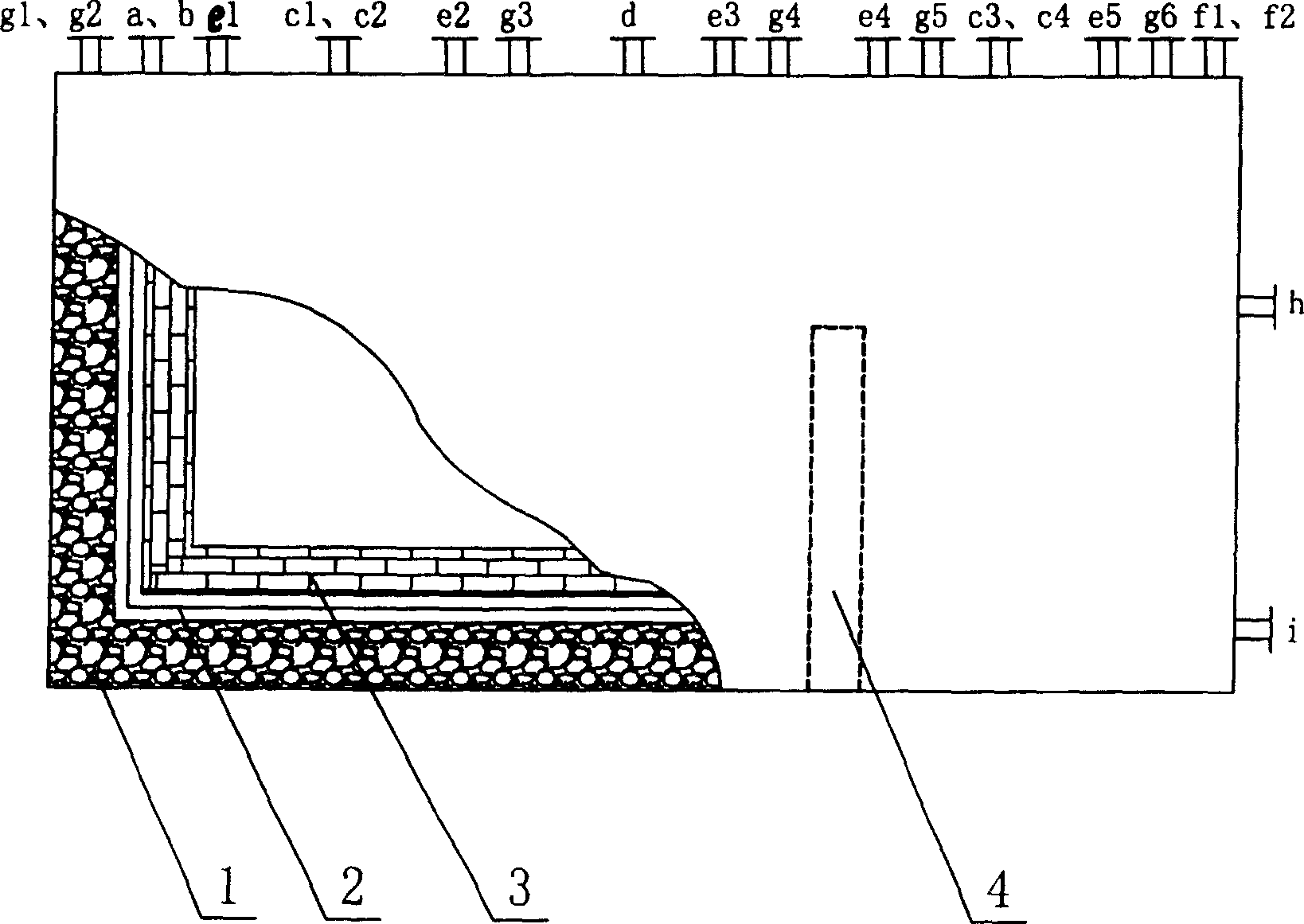

[0026] Such as figure 2 As shown, the potassium chloride low-temperature continuous conversion steam heating equipment of the present invention has a rectangular reaction tank, 5 to 7 evenly distributed steam inlets g are arranged on the top cover of the reaction tank, and a steam inlet g is arranged on the left end of the top cover. Potassium chloride inlet a and sulfuric acid inlet b, 4 to 6 stirring paddle ports e evenly distributed in the left and right directions of the top cover, 2 to 4 thermometer ports c on the left and right parts of the top cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com