Rolling mill for wire rod material and tandem mill set

A technology for rolling mills and wire rods, applied in the field of on-line bar rolling mills and continuous rolling mills, can solve the problems of complex and large structures, large vibrations, and difficulty in realization, and achieve the effects of simplified precision adjustment, easy processing, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0075] Specific implementation method (only in the form of continuous rolling, without involving the use of reversible Y-type rolling for billet opening and rough rolling):

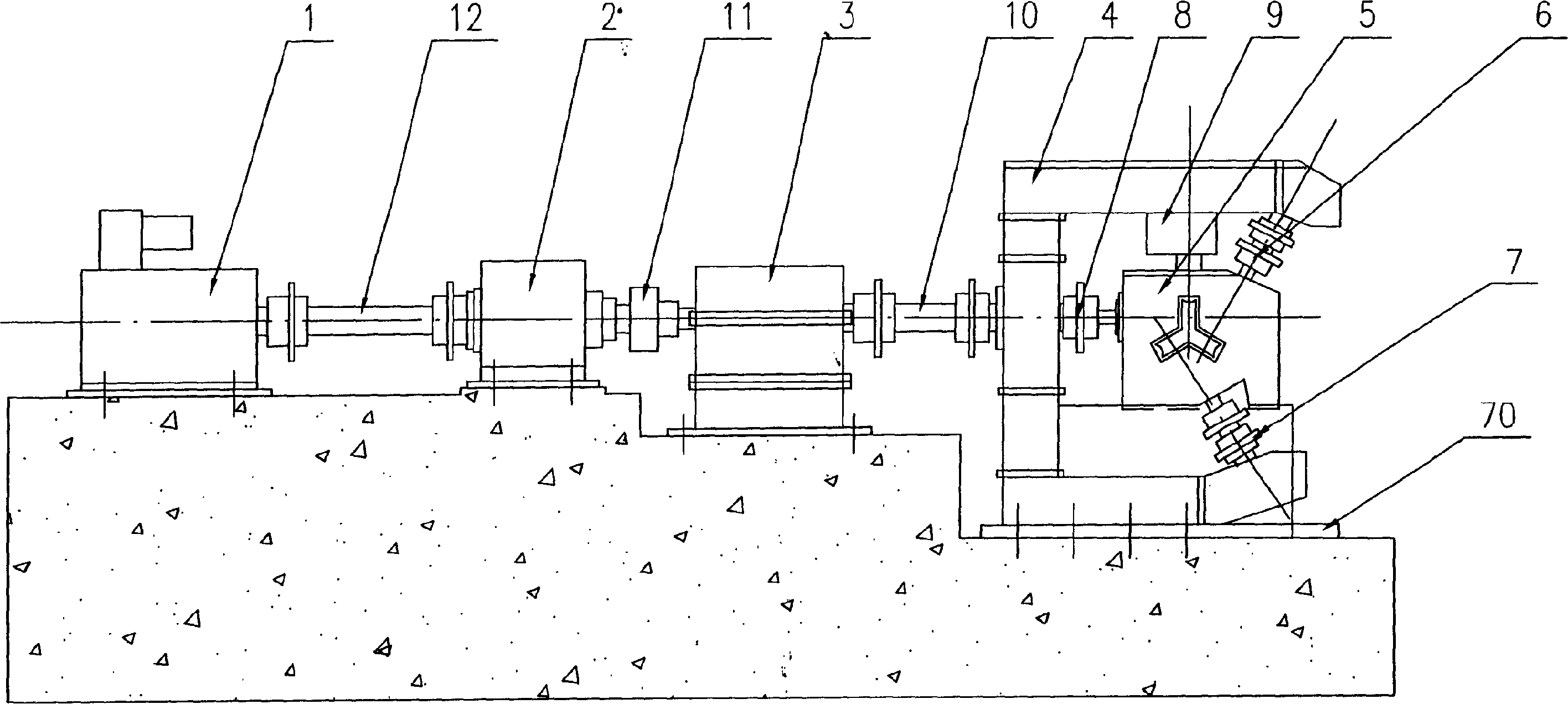

[0076] figure 1 4 is the C-type transmission box, and 5 is the working stand of the rolling mill. C The power of the type transmission box 4 is transmitted to the rolling mill 5 respectively, and the C type transmission box is fixed on the base 70. Coupling 10 transmits power to the linkage box, 1 is the main motor, and power is transmitted to the planetary reducer through coupling 12, and 9 is the hydraulic system for fixing the working stand of the rolling mill.

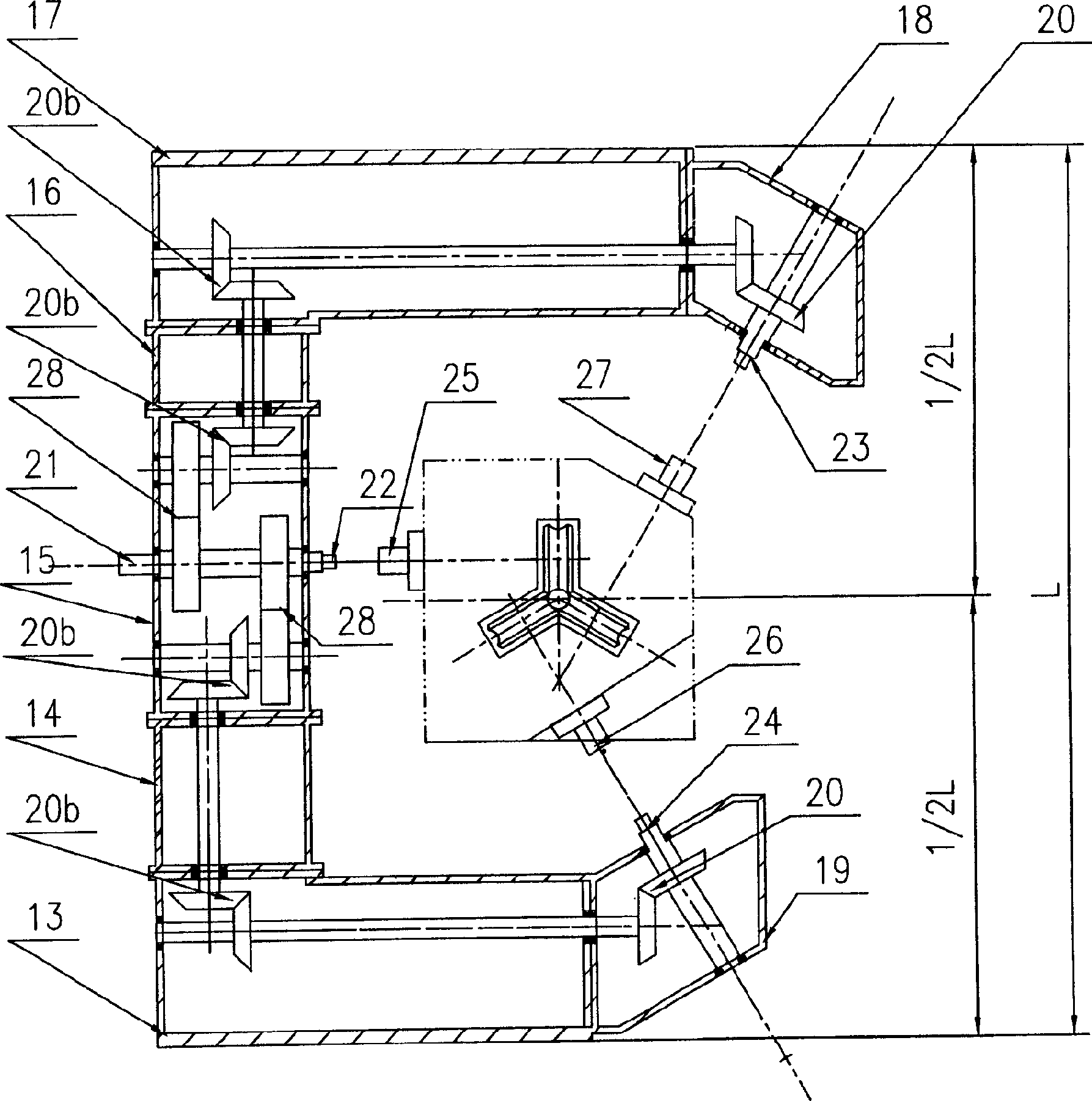

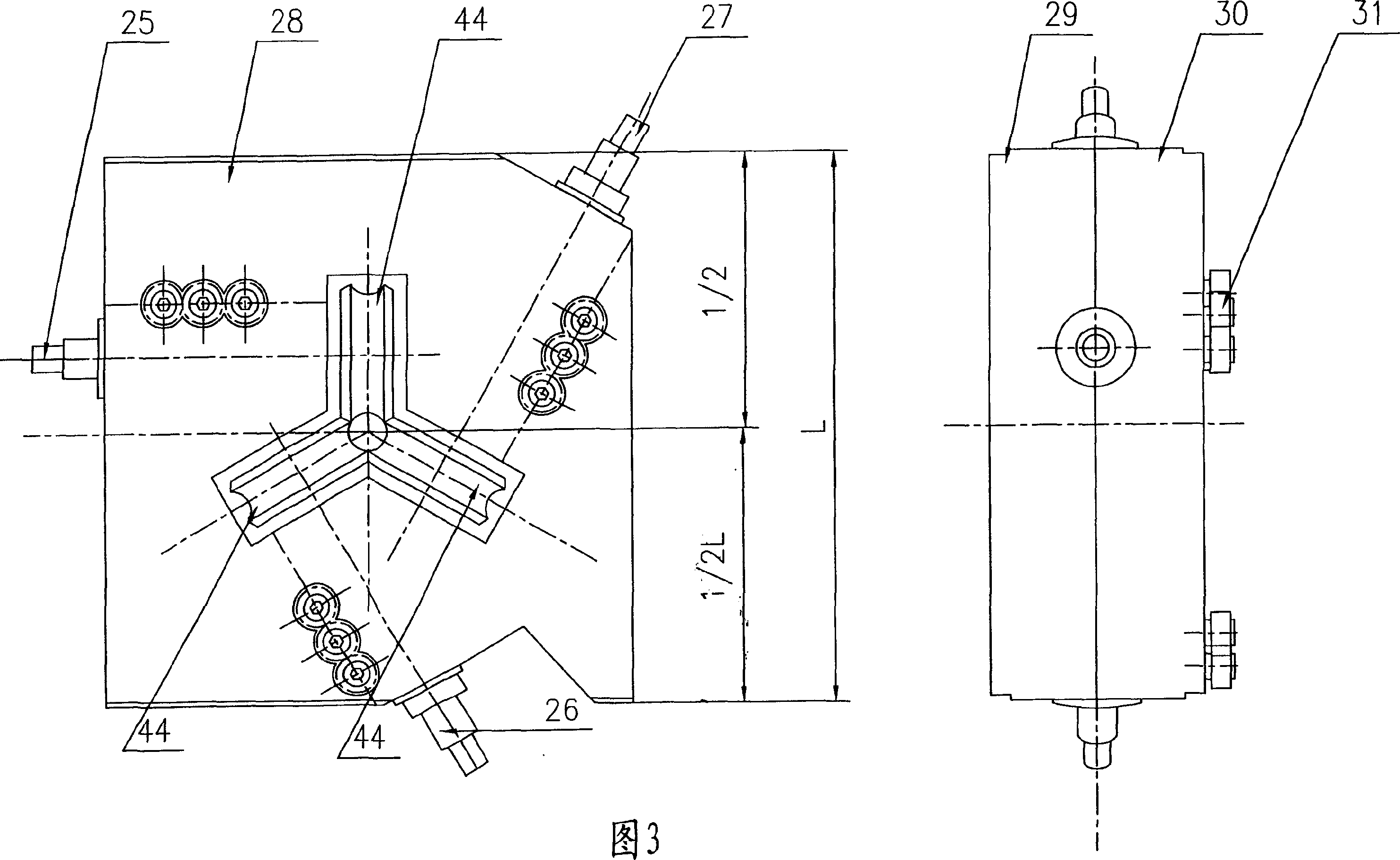

[0077] figure 2 It is a new Y-type three-roll mill C-type transmission box, and its box body is composed of horizontal box bodies 13, 17 with mounting holes, main box bodies 14, 15, 16 and inclined box bodies 18, 19 and other seven bolts (not shown). 20, 20b, 28 represent 8 pairs of gear trains that divide the main transmission into three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com