Degradable porous glass rack having bioactivity and preparation method

A bioactive glass, glass technology, applied in glass manufacturing equipment, glass molding, manufacturing tools and other directions, can solve the problems of poor applicability of stent materials, affecting the use effect, easy to break, etc., to achieve good biological interface and chemical properties, The effect of good biological activity, good degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The raw materials used are as described above.

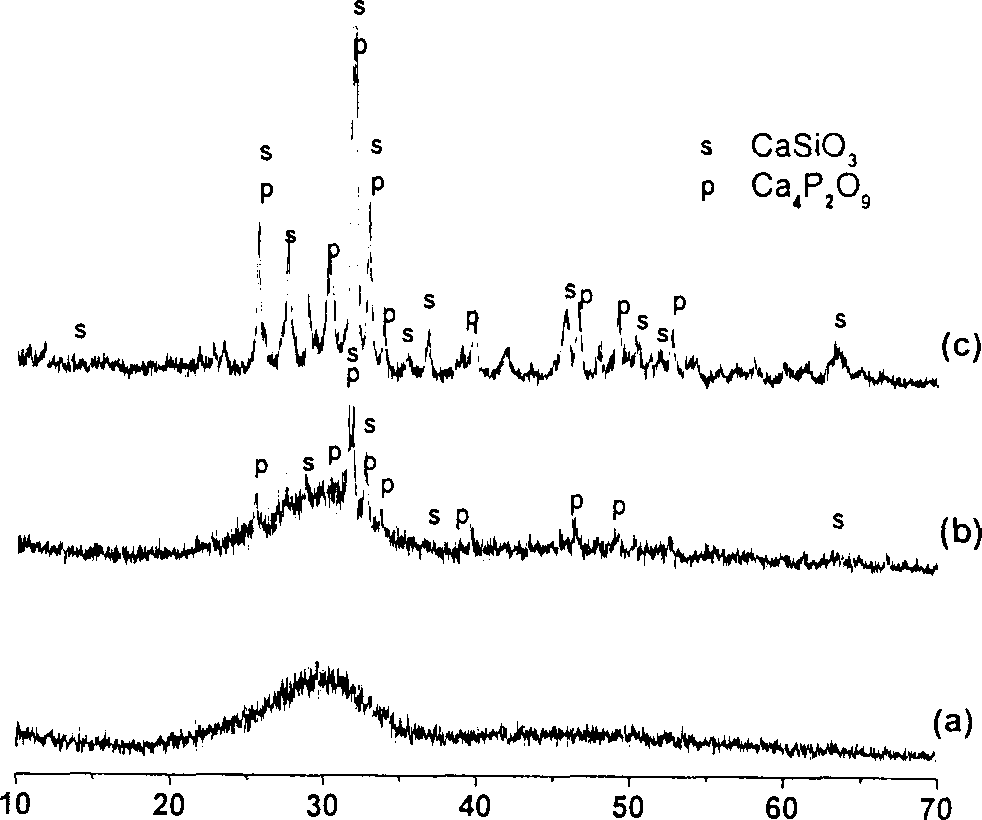

[0042] will analyze pure SiO 2 , Na 2 CO 3 , CaCO 3 , P 2 o 5 The raw materials are uniformly mixed in proportion, melted into a homogeneous melt at 1420°C, then cooled, pulverized, and sieved to obtain bioactive glass powder with a particle size of 40-300um. The composition of the glass powder is CaO 24.5%, SiO 2 45%, Na 2 O 24.5%, P 2 o 5 6%.

[0043] Mix the bioactive glass powder with a particle size of 150-200 microns and the polyethylene glycol powder with a particle size of 200-300 microns at a mass percentage of 60:40, and add a polyvinyl alcohol solution with a concentration of 6% as a binder. After mixing evenly, dry press molding under 14MPa pressure, and release the biscuit of porous material. The green compact is ejected at 400° C., and then sintered at 850° C. for 2 hours to obtain the porous material of the present invention with a compressive strength of about 1.25 MPa and a porosity of about 5...

Embodiment 2

[0046] will analyze pure SiO 2 , CaCO 3 , Ca 3 (PO 4 ) 2 , MgCO 3 , CaF 2 The raw materials are uniformly mixed in proportion, melted into a homogeneous melt at 1450°C, then cooled, pulverized, and sieved to obtain bioactive glass powder with a particle size of 40-300um. The composition of the glass powder is CaO 40.5%, SiO 2 39.2%, MgO 4.5%, P 2 o 5 15.5%, CaF 2 0.3%.

[0047] The obtained powder is mixed according to the mass percentage of bioactive glass powder and 300-600 micron polyvinyl alcohol powder in a ratio of 50:50 to obtain a solid mixture. Prepare an aqueous solution containing 20% acrylamide, 2% N, N'-methylenebisacrylamide and 8% polyacrylamide, mix 10 grams of the above-mentioned solid mixture with the above-mentioned aqueous solution at a ratio of 50:50 by volume Mix evenly, add a few drops of 3% ammonium persulfate by mass percent and 3% by mass percent N, N, N', N'-tetramethylethylenediamine, stir evenly to obtain a slurry with good fluidity...

Embodiment 3

[0049] The raw materials used and the preparation method of the bioactive glass powder are the same as in Example 2.

[0050] Mix bioactive glass powder with a particle size of 150-200 microns and PEG powder with a particle size of 200-300 microns at a mass ratio of 40:60, add polyvinyl alcohol solution with a concentration of 6% as a binder, and mix well. Dry press molding under 14MPa pressure, demoulding the biscuit of porous material. The green body is ejected at 400°C and then sintered at 800°C to obtain the porous material of the present invention with a compressive strength of about 1.5 MPa and a porosity of about 65%. After soaking in simulated body fluid for 3 days, the degradation rate was 38% (mass percentage of dissolved Si). The performance evaluation of the porous material is as in Example 1. It can be used as a scaffold for bone tissue culture in vitro.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com