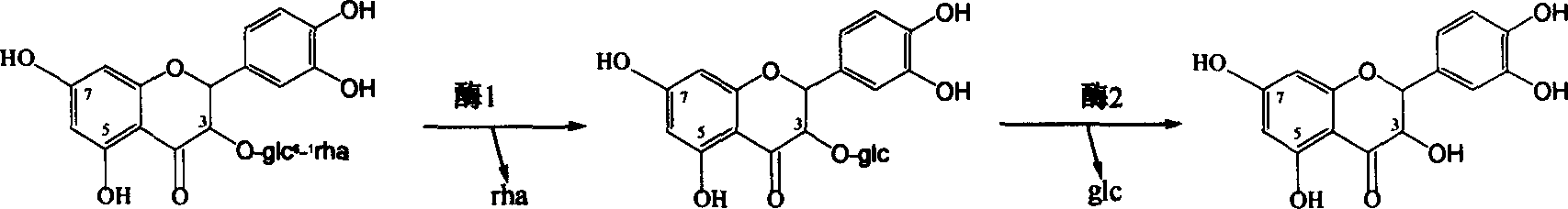

Method for preparing isoquercetin and quercetin by enzymatic method and hydrolyzing rutin

A technology for isoquercetin and quercetin, which is applied in biochemical equipment and methods, microorganism-based methods, microorganisms, etc., can solve the problems of less isoquercetin, complicated processes, and inability to produce quercetin, and achieves high productivity. The effect of large output, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a. With the thermoaerobic bacteria Bacillus sp.JF (document 1), in 0.01mol MgSO containing 3% corn flour, 1% enzyme-producing inducer - Sophora japonica extract (dry matter) 4 culture medium at 60°C for 30-40 hours, centrifuge and sterilize to obtain an enzyme-containing mixture, add 70% ethanol to precipitate the enzyme protein, collect the protein, and freeze-dry to obtain rutin-hydrolyzing α-rhamna Glycosyl enzymes.

[0020] b. Dissolve 4 grams of the above enzyme in 150 milliliters of 0.02 M phosphate buffer of pH 6; mix 9 grams of rutin monomer with 103 milliliters of 0.02 M phosphate buffer of pH 7 and 47 milliliters of 95% ethanol. The above two solutions are mixed, the concentration of the reactant rutin is 0.01-10%, the concentration of ethanol is 0-35%, and the reaction is stirred and reacted at a temperature of 60° C. for 10 hours.

[0021] c. After the reaction, add 24 grams of NaOH to the solution, filter to remove the protein precipitate, add 300ml 2N HCl...

Embodiment 2

[0024] a. with Aspergillus oryzae in the culture medium containing 4% corn flour, 1% enzyme-producing inducer-Sophora japonica extract (dry matter), cultured under ventilation at 30°C for 30-40 hours, and then sterilized, The culture medium was precipitated with 75% saturated ammonium sulfate, and the precipitate was collected, diluted to 1 / 5 of the volume of the culture medium with 0.02M sodium acetate buffer solution of pH 5.8, dialyzed, and centrifuged to remove slag, which was the enzyme solution.

[0025] b. Take 50 milliliters of the above-mentioned enzyme solution, 10 grams of rutin monomer, 5 liters of pH6 0.02M phosphate buffer and 50 milliliters of 95% ethanol and mix evenly, so that the concentration of the reactant rutin is 0.01-10%, and the concentration of ethanol 0-35%, stirred and reacted at a temperature of 70°C for 2 hours.

[0026] c. After the reaction, add 24 grams of NaOH to the solution, filter to remove the protein precipitate, add 300ml 2N HCl to the f...

Embodiment 3

[0029] a. Use Aspergillus niger (Aspergillus niger) in the medium containing 4% malt extract and 0.5% ginseng extract, ventilate and cultivate at a temperature of 30°C for 30-40 hours, sterilize after cultivation, and use 80% saturated sulfuric acid for the culture solution Precipitate the enzyme protein with ammonium, collect the precipitate, dissolve it with 0.02M sodium acetate buffer solution with pH 5.8, dialyze to remove ammonium sulfate, centrifuge to remove residue, and freeze-dry to obtain the enzyme.

[0030] b. Get 7 grams of the above-mentioned enzyme and dissolve in 200 milliliters of pH5.8 0.02M sodium acetate buffer; get 12 grams of commercially available rutin monomer and 115 milliliters of 0.02M sodium acetate buffer of pH5.8 and 85 milliliters 95% ethanol is mixed evenly, the concentration of the reactant rutin is 0.01-10%, and the concentration of ethanol is 0-35%, and the reaction is stirred and reacted at a temperature of 15° C. for 24 hours.

[0031] c. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com