Magnetic support electrical drive device

A technology of electric drive and magnetic support, applied to synchronous motors with stationary armatures and rotating magnets, electric components, bearings, etc., can solve the problem of large number of coils, and achieve the effect of high attenuation and increased stability range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

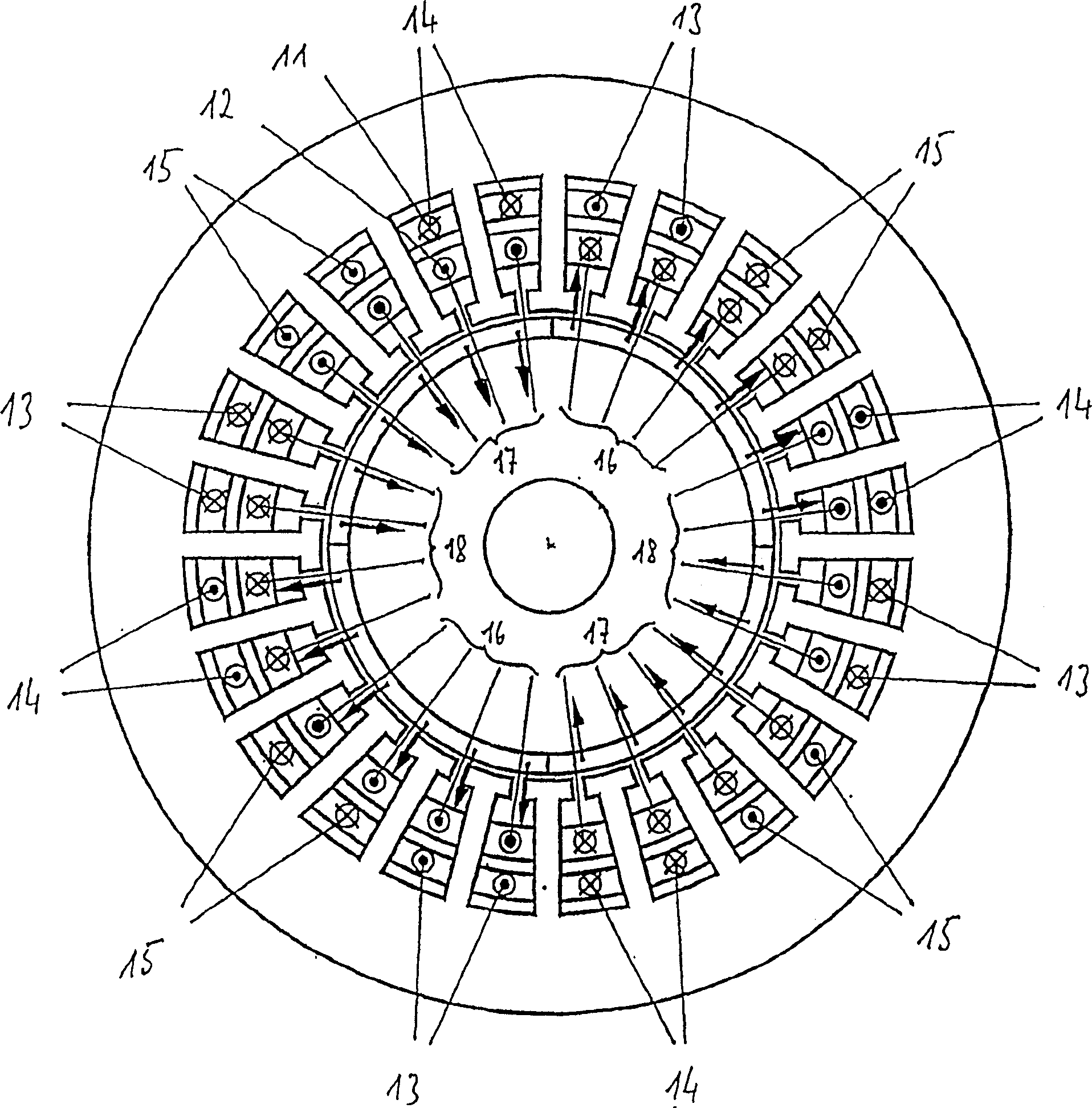

[0039] The following examples illustrate possible embodiments of the invention.

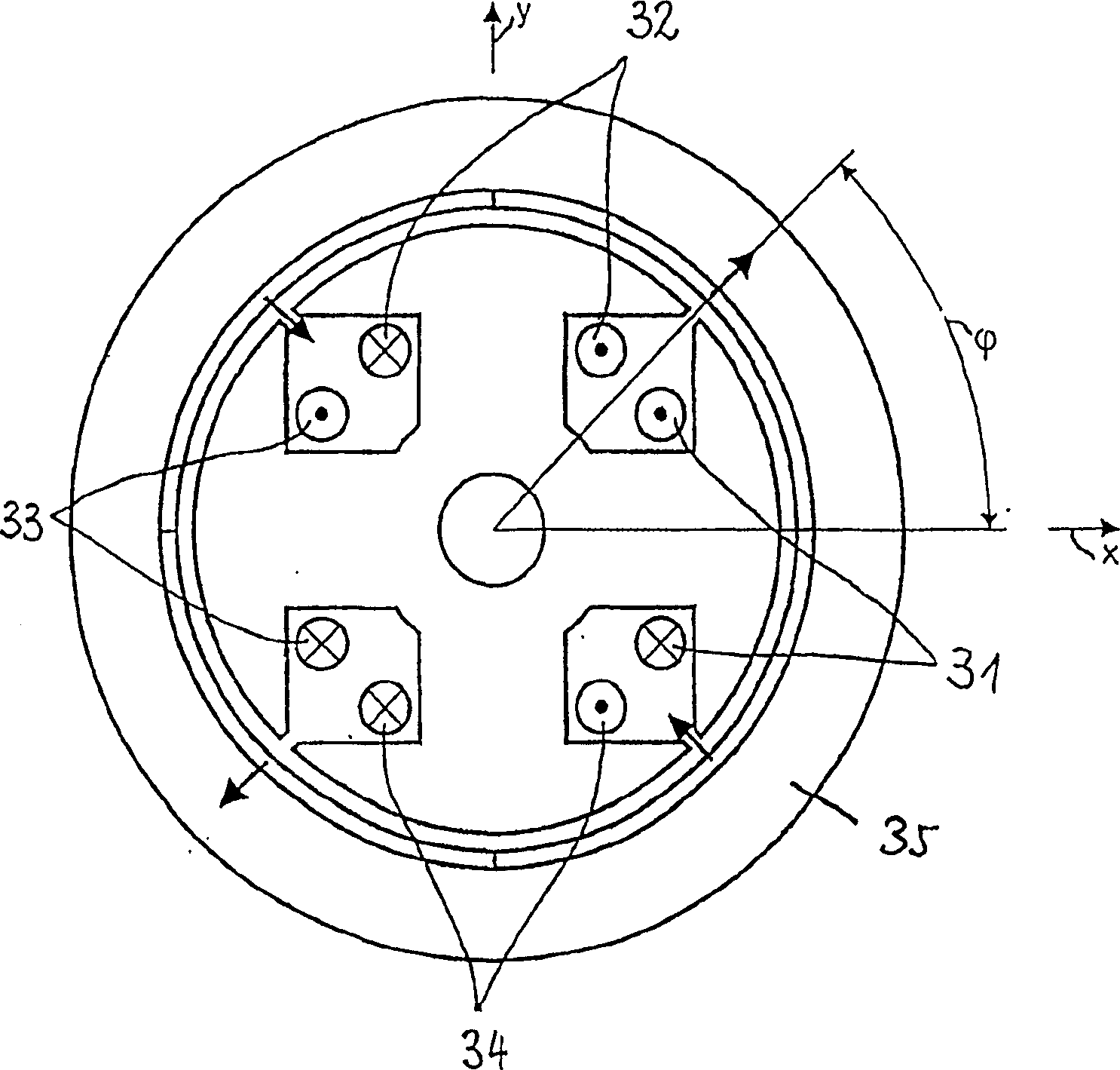

[0040] Figure 4A motor with 5 concentrated individual coils 41 , 42 , 43 , 44 , 45 is shown. With this stator arrangement, usually with superimposed current components flowing through the coils, both a bipolar rotating magnetic field and a quadrupole magnetic field or two bipolar and quadrupole magnetic potentials can be obtained simultaneously. Therefore, on a two-pole rotor, a torque can be obtained by cooperating with the two-pole winding magnetic potential, and a radial supporting force can be obtained by cooperating with the four-pole winding magnetic potential.

[0041] An odd number of coils or cores not divisible by the two pole numbers 4 and 2 used results in an asymmetrical core cross-section and an asymmetrical magnetic potential distribution or field distribution in the area of the stator or air gap.

[0042] Therefore, the coil current is determined according to the angular posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com