Method and apparatus for flyash bottom-feeding circulating fluidized bed for fire-resistance fuel

A technology of circulating fluidized bed and combustion device, which is applied in the direction of fluidized bed combustion equipment, combustion method, fuel burned in a molten state, etc., and can solve the problem of high combustible content, short residence time and low boiler efficiency when burning active fly ash and other problems, to achieve the effect of stable conveying, reduced leakage and uniform air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

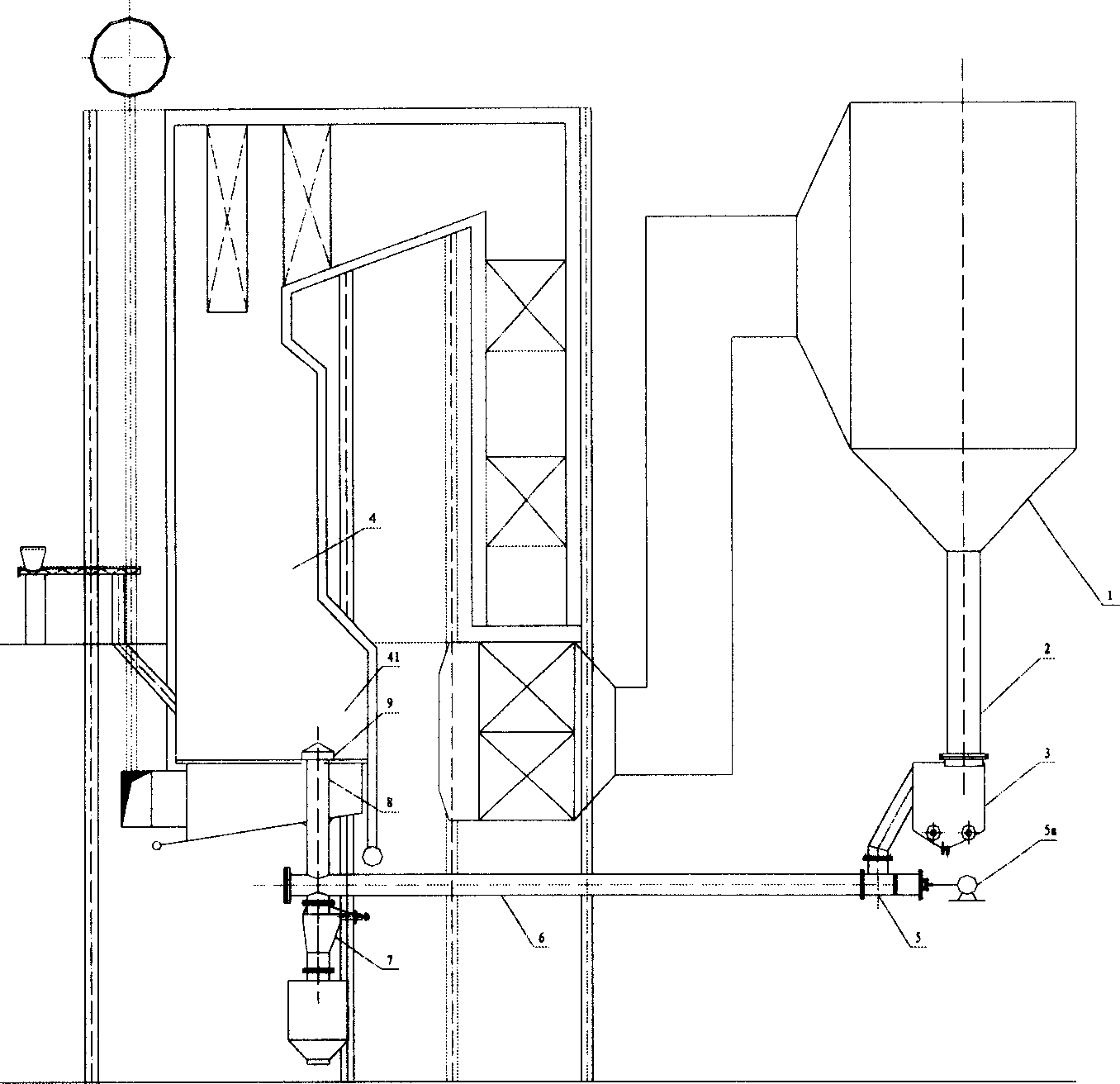

[0032] Example 1 A combustion method of fly ash bottom-fed circulating fluidized bed for flame retardant fuel, using fly ash collector 1 such as: electrostatic precipitator to capture the fly ash with high combustible content in the flue gas, and make the fly ash pass through The standpipe 2 enters the return controller 3, and then is sent to the return pipe by the delivery injector 5, and then returned to the dense phase area 41 in the bed by the high temperature resistant and wear-resistant bottom feeding nozzle 9 for combustion.

Embodiment 2

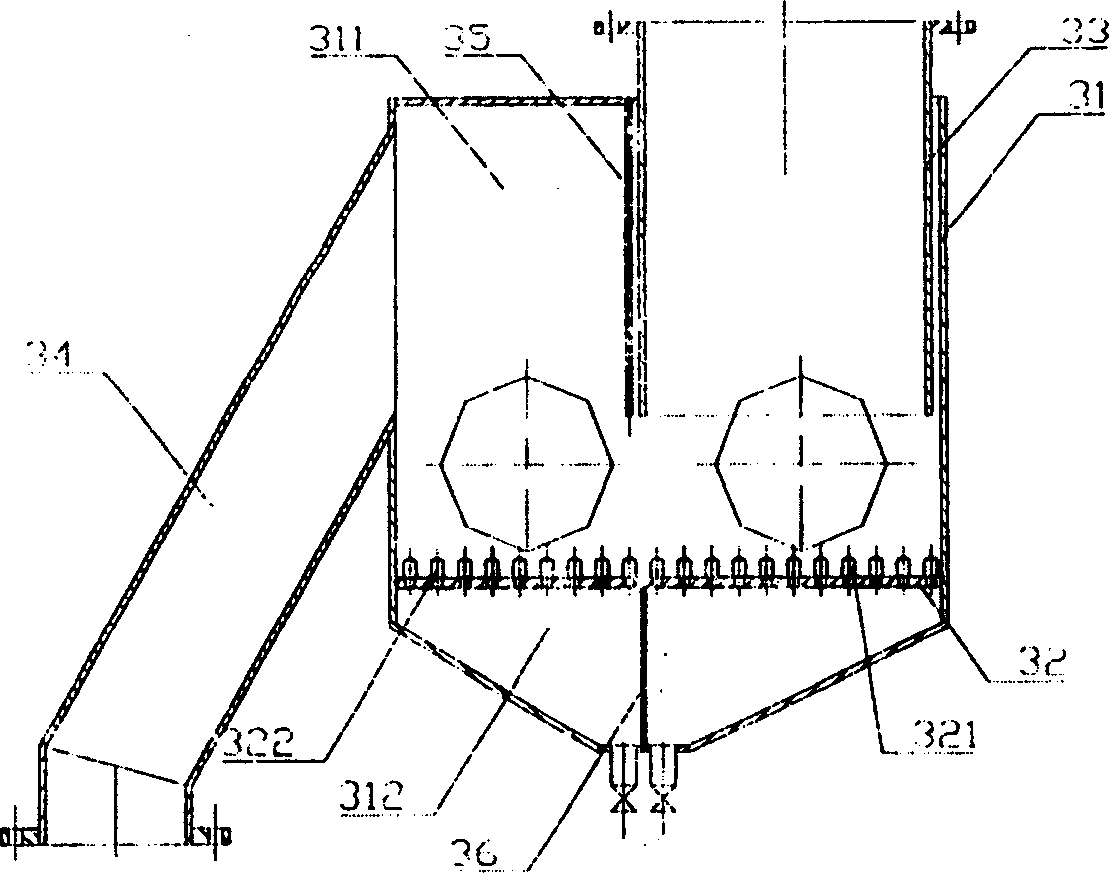

[0033]Example 2 A combustion device for implementing the above method is composed of a fly ash collector 1, a return controller 3, a pneumatic conveying injector 5 and a combustion furnace 4. The upper part of the combustion furnace 4 is connected to the fly ash collector 1 The fly ash collected by the fly ash collector 1, after passing through the return controller 3, is sent to the combustion chamber by the pneumatic conveying injector 5 through the bottom feeding nozzle 9 on the air distribution plate in the combustion furnace 4. In the dense-phase area 41 of the furnace 4, the return controller 3 includes a housing 31, a bed body 311 and an air chamber 312 are arranged in the housing 31, and an air distribution plate 32 is arranged between the bed body 311 and the air chamber 312. The chamber 312 is provided with an air inlet, and the bed body 311 is provided with a standpipe 33 and ash pipe 34. The standpipe 33 extends into the casing 31, and its end is higher than the ape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com