Organic photochromic composite nano materials and method for preparing same

A nanocomposite material and photochromic technology, applied in the direction of luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve the complex problems of organic photochromic materials, achieve fast fading, high chroma, and excellent fatigue resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

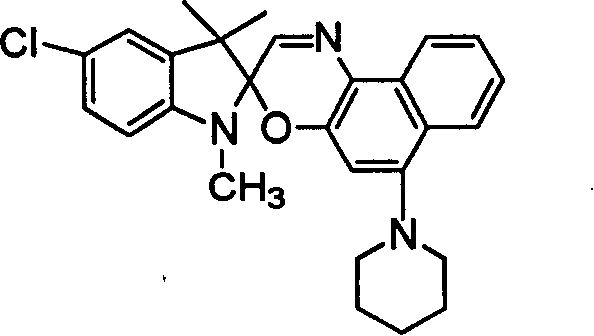

Image

Examples

Embodiment 1

[0029] Preparation of photochromic nano-composite material: Weigh 8g of the above-mentioned photochromic compound 1, add 50mL of dichloromethane and stir to dissolve it below 25°C, then add 1g of N,N-diethyl lauramide as a high boiling point solvent, After stirring evenly, add 40g solid PET (polyethylene terephthalate) nanoscale resin powder under stirring, antioxidant 2,2'-methylene bis(4-methyl-6-tert-butylphenol ) 0.8 grams, the light stabilizer is (LS-770), sebacic acid bis (2,2,6,6-tetramethyl-4-hydroxypiperidine) ester 0.1 grams, singlet oxygen quencher, N, Nickel N-di-n-butyldithiocarbamate (UV-NBC) 0.1 g. Stir well to fully absorb. Then dichloromethane, a low-boiling solvent, was thoroughly distilled off under reduced pressure to obtain a photochromic nanocomposite material. Compound: Carrier: Antioxidant: Light Stabilizer: Singlet Oxygen Quencher by weight ratio 8:40:0.8:0.1:0.1.

[0030] Detection:

[0031] With the above-mentioned colorless photochromic nanocomp...

Embodiment 2

[0033] Automobile and architectural glass are prepared with photochromic PVB film. Weigh 50g of the photochromic nano-composite fine powder prepared above, stir and mix with 2000g of PVB resin powder, then add 100mL of PVB plasticizer, stir and mix well, and extrude by heating at 160°C under nitrogen protection. Photochromic PVB film. (film machine: Brabender model: PLE-330)

Embodiment 3

[0035] Preparation of photochromic printing pastes. The method is: weigh 50g of the photochromic nano-composite fine powder prepared above, add it to 500g of printing and dyeing paste, sand and pulverize it thoroughly, and make photochromic printing and dyeing paste after it is completely uniform, and then print and dye them on clothing separately. Apparel and travel cultural shirts, showing beautiful patterns in various colors under sunlight or ultraviolet light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com