Method for processing ginkgo leaves products used for cigarette

A processing method and ginkgo leaf technology are applied in the processing field of ginkgo leaf products, can solve problems such as toxic and side effects, and achieve the effects of reducing toxic and side effects, high component utilization rate, and convenient production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

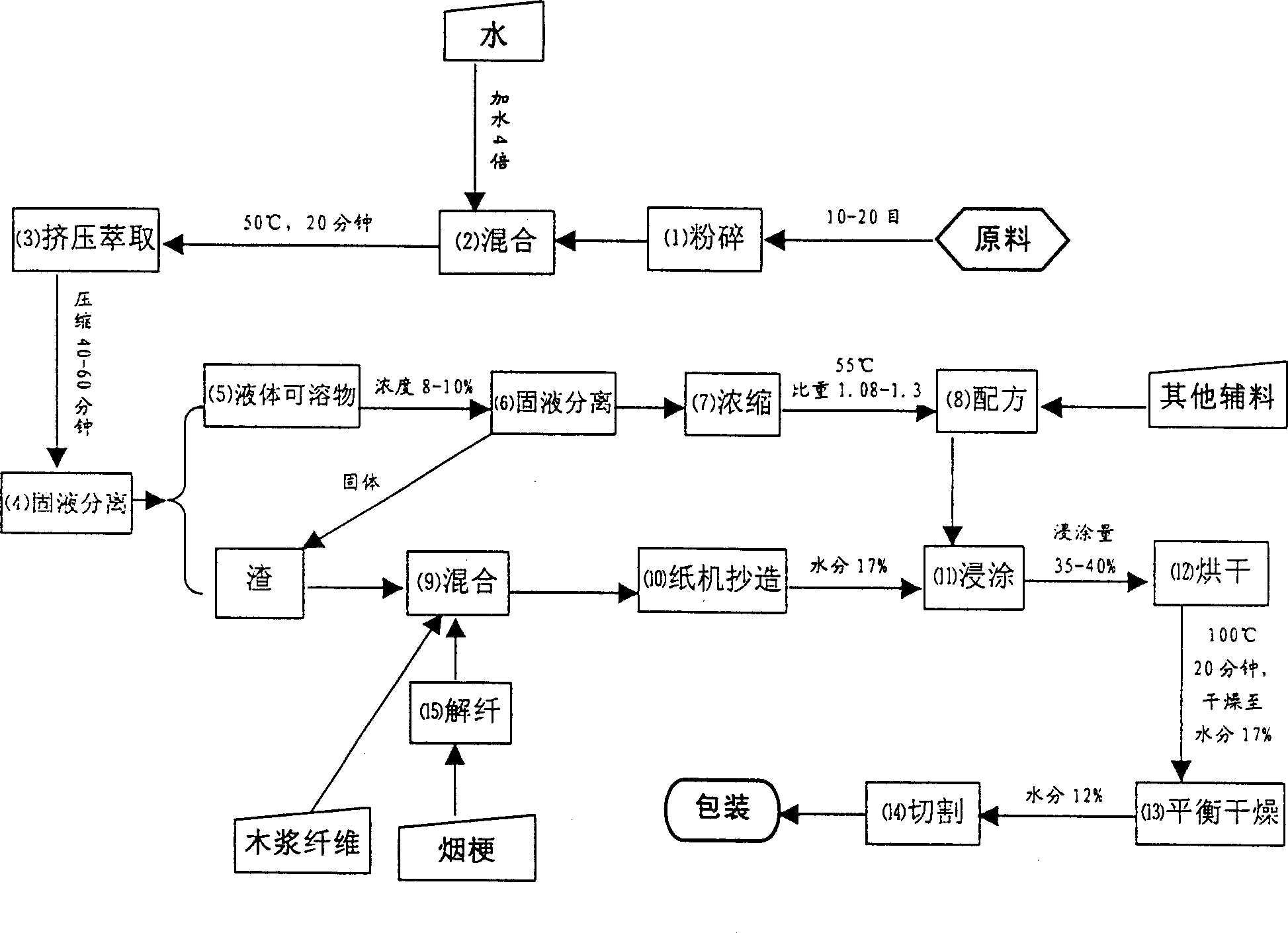

Image

Examples

Embodiment 1

[0030] Take 1 ton of naturally mature and naturally dried ginkgo leaves (Ginkgo leaves in August) to remove soil and sundries, crush them with a crusher to a powder with a diameter of 1.6-2.2 mm, pour them into the leaching treatment cylinder, and add the above-mentioned ginkgo leaf raw materials into the cylinder Mix the water with 4 times the volume of the minced powder, soak it at 50°C for 30 minutes, squeeze the above-mentioned ginkgo leaf minced water extract for 50 minutes, and initially separate it into juice and sediment; adjust the concentration of the obtained juice with water When the mass volume percentage is 10%, let stand for 60 minutes to precipitate the solid matter in the juice, separate the separated solid matter and mix with the above sediment, and set aside; then heat and concentrate the remaining juice at a temperature of 55°C to adjust to the specific gravity of the juice Up to 1.2; in the above-mentioned prepared concentrated juice, adding mass volume per...

Embodiment 2

[0035] Take 1 ton of naturally mature and naturally dried ginkgo leaves (Ginkgo leaves in August) to remove soil and sundries, crush them with a crusher to a powder with a diameter of 1.6-2.2 mm, pour them into the leaching treatment cylinder, and add the above-mentioned ginkgo leaf raw materials into the cylinder 3 times the volume of the minced water, mix well, soak at 50°C for 20 minutes, squeeze the above-mentioned ginkgo leaf minced water extract for 40 minutes, and initially separate it into juice and sediment; adjust the concentration of the obtained juice with water When the mass volume percentage is 8%, let it stand for 80 minutes to precipitate the solid matter in the juice, separate the separated solid matter and mix it with the above-mentioned sediment for use; then heat and concentrate the remaining juice at a temperature of 55°C to adjust to the specific gravity of the juice Reach till 1.3; In the concentrated juice of above-mentioned deployment, add the essence a...

Embodiment 3

[0040] Take 1 ton of naturally mature and naturally dried ginkgo leaves (Ginkgo leaves in August) to remove soil and sundries, crush them into powders with a diameter of 1.8-2.2 mm, pour them into the leaching treatment cylinder, and add the above-mentioned ginkgo leaf raw materials into the cylinder 3.5 times the volume of the minced water, mix well, soak at 50°C for 25 minutes, squeeze the above-mentioned ginkgo leaf minced water extract for 60 minutes, and initially separate it into juice and sediment; adjust the concentration of the obtained juice with water When the mass volume percentage is 9%, let it stand for 50 minutes to precipitate the solids in the juice, separate the separated solids and mix them with the above-mentioned sediment, and set aside; then heat and concentrate the remaining juice at 55°C to adjust to the specific gravity of the juice Reach till 1.25; In the concentrated juice of above-mentioned deployment, add the essence and fragrance that mass volume p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com