Phospholipid-based removal method of sterols from fats and oil

A technology of sterols and phospholipids, which is applied in the field of removing sterols in fat and oil based on phospholipids, can solve the problems of increasing the cost of waste, reduce deterioration, improve the value of nutritional medicines, reduce costs and the possibility of thermal deterioration of products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Add different proportions of distilled water and soybean lecithin (Lipotin A / UB, SR #19697 / 1 available from Lucas Meyer, Decatur, IL). The samples were stirred vigorously with a magnetic stirrer for 1 hour at ambient temperature, and then centrifuged at 3000 rpm (approximately 1000 xg) for 10 minutes in a benchtop centrifuge (IEC Clinical Centrifuge).

[0053] After centrifugation, the upper lipid layer was collected and analyzed for cholesterol content by gas chromatography. Oil samples were processed only once. This allowed the determination of the maximum amount of cholesterol removed in a single-step process under different conditions. The results are shown in Table 1 below:

[0054] Table 1

[0055] One-step process to remove cholesterol from fats

[0056] sample cholesterol * Lecithin: Water Lecithin: Fat Cholesterol removal

[0057] No. mg / 100g weight ratio weight ratio to percentage

[0058] ...

Embodiment 2

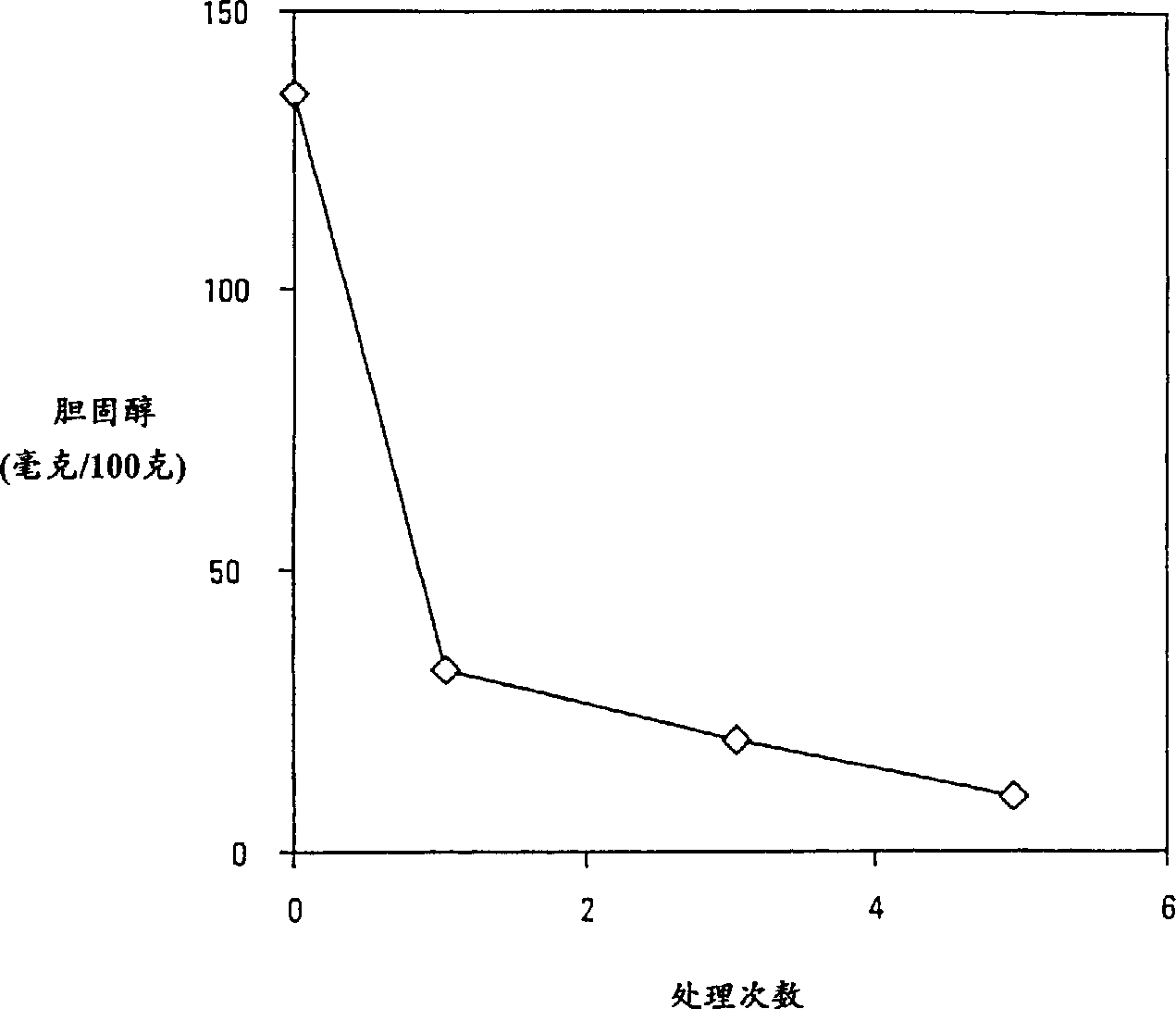

[0066] In the second experiment, an appropriate amount of distilled water was added to the same commercial soybean lecithin used in Example 1, and then heated to 60°C. The mixture was homogenized with a mechanical stirrer (Caframo model RZR1) for 15 minutes to form a slurry of lecithin and water. The remaining steps were performed at ambient temperature. Add the weighed lecithin-water paste into different amounts of the same type of liquid tallow used in Example 1, and mix thoroughly for 10 minutes with a high-speed shear mixer. Samples were then centrifuged at 10000 rpm (approximately 11400 xg) for 10 minutes in a Beckman J-21C floor-standing centrifuge. Separate the oily phase from the centrifuge bottle. The steps of contacting the once treated oil with the lecithin-water slurry, mixing, centrifuging and separating are repeated as many times as desired. Fresh lecithin-water paste was used for each repetition. The resulting cholesterol-depleted oil was then subjected to c...

Embodiment 3

[0073]In the third set of experiments, phosphatidylcholine derived from egg yolk (Sigma Chemical Co., St. Louis, MO; No. P-9671; phosphatidylcholine content about 60%) was used as a source of phospholipids. A slurry of phosphatidylcholine and water was prepared by mixing water and phosphatidylcholine in a weight ratio of 2:1 with a mechanical stirrer. The phosphatidylcholine used in this experiment contained only trace amounts of oil, whereas the soybean lecithin used in the previous examples contained about 50% by weight of oil. Thus, the phospholipid content of the 2:1 water to phosphatidylcholine slurry was approximately equal to the phospholipid content of the 1:1 water:lecithin slurry used in the previous examples. Liquid fats and oils (same type as in Examples 1 and 2) were treated with phosphatidylcholine-water paste with a ratio of phosphatidylcholine to fat of 1:20 to 1:10. The paste and fat were stirred rapidly with a mechanical stirrer for 30 minutes at ambient tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com