Apparatus and process for producing acetylene by plasma pyrolysis of coal and natural gas

A technology of plasma and natural gas, applied in the direction of organic chemistry, etc., can solve the problems of insufficient utilization of self-generated heat, inability to be used as auxiliary gas, single plasma generator, etc., achieve compact structure, increase continuous running time, and suppress coking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

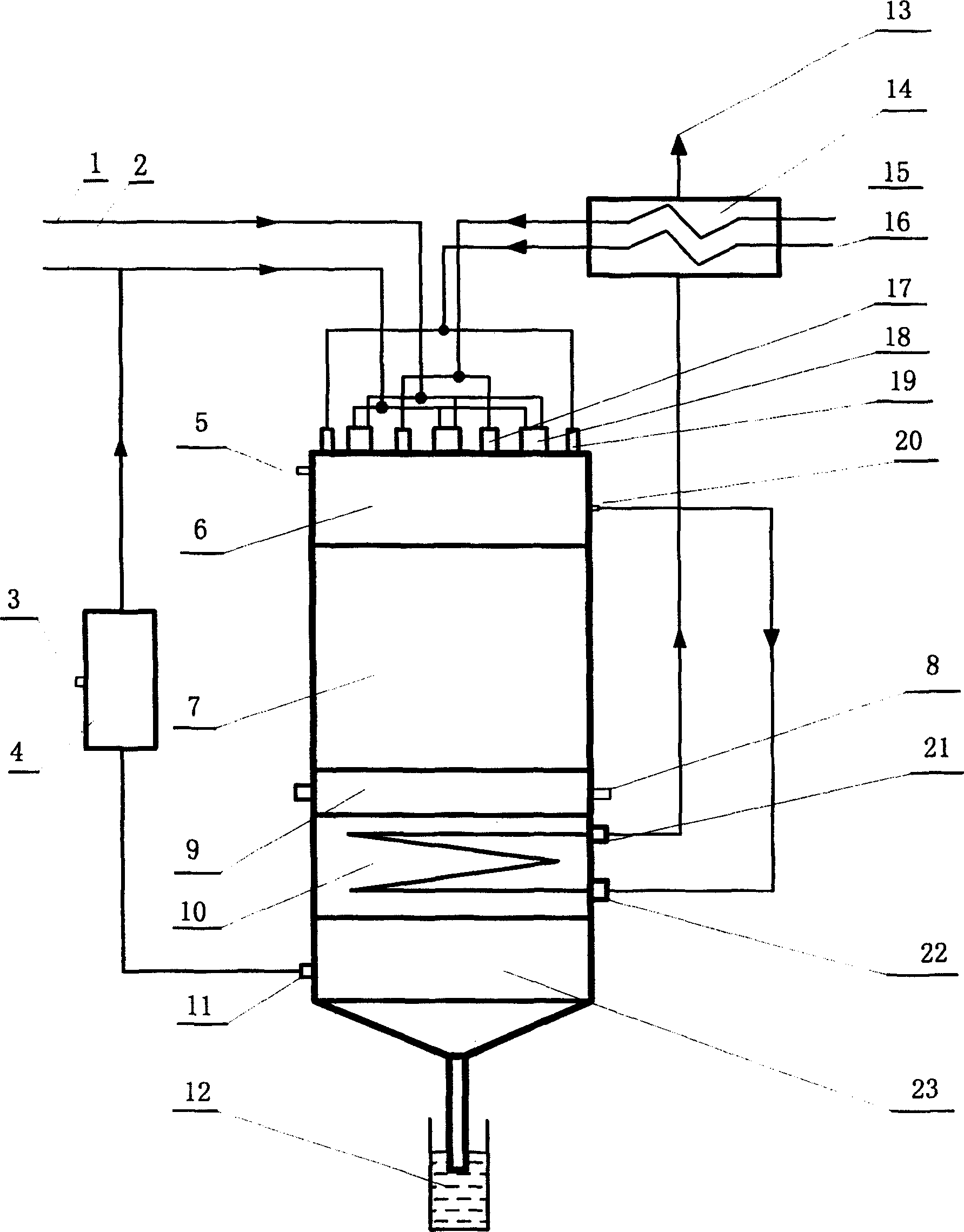

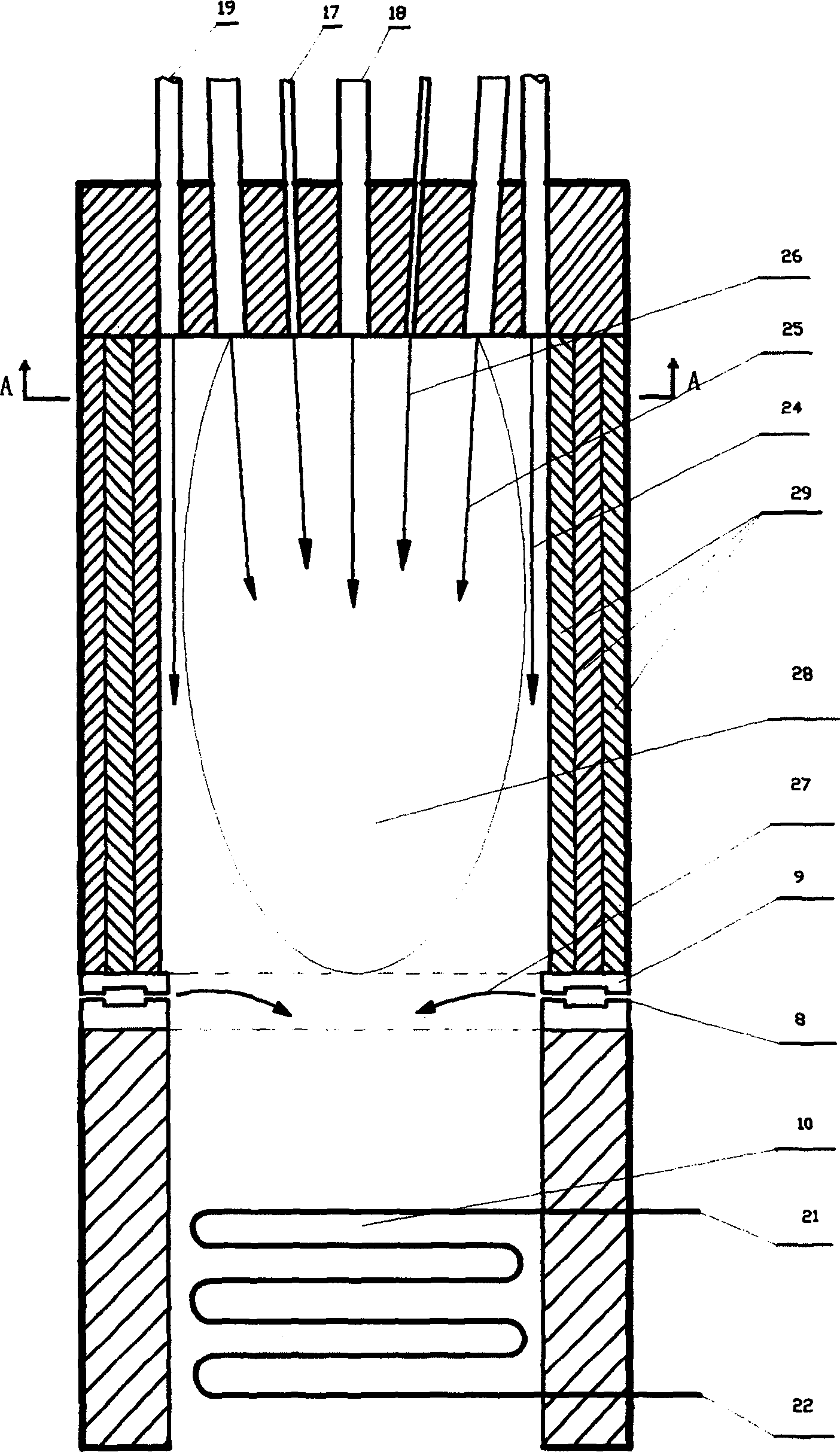

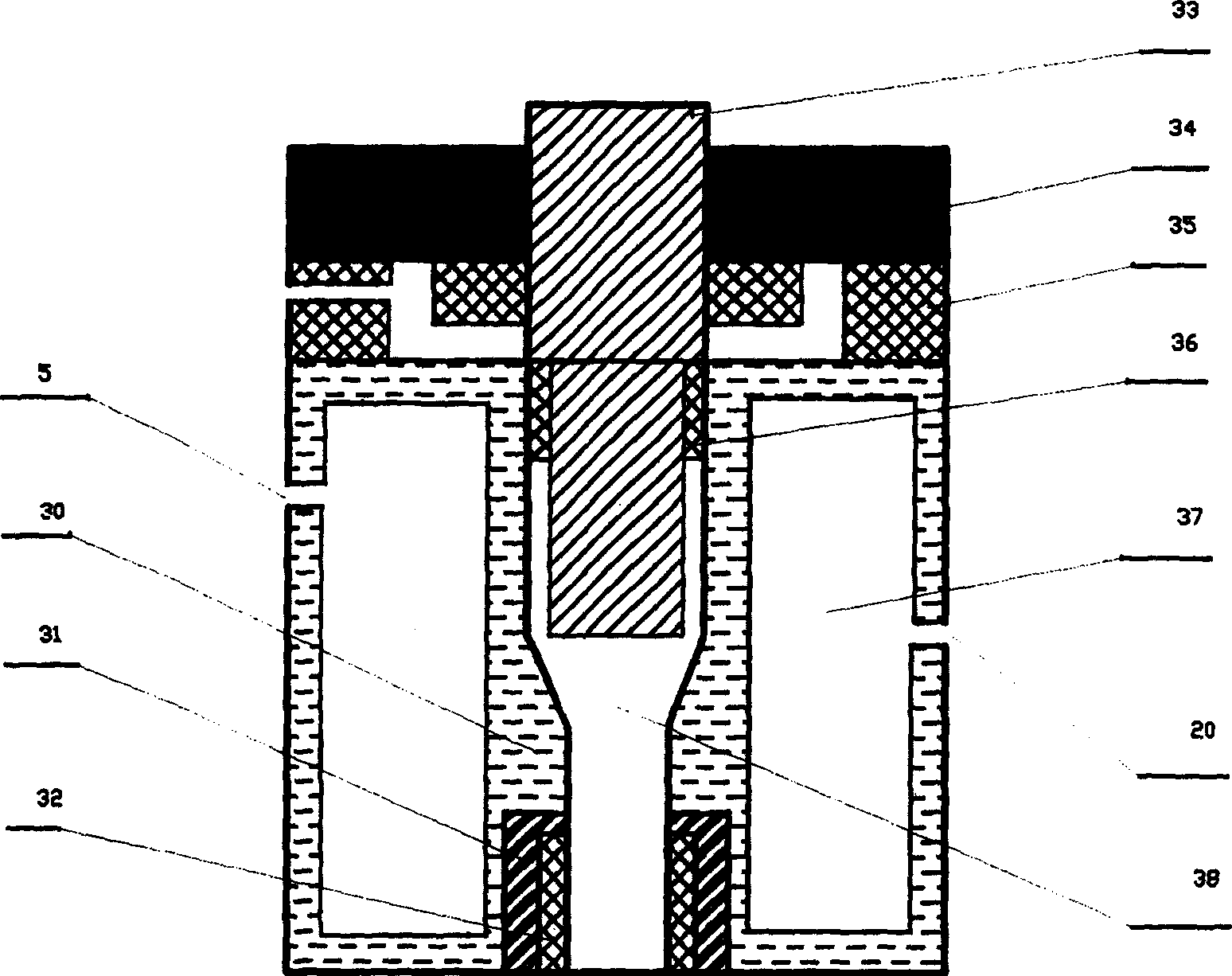

[0022] The present invention improves it on the basis of existing technology, as attached figure 1 As shown, in the plasma generator (6), at first by the mixed gas inlet of argon and hydrogen, i.e. the working gas inlet (2) into the working gas, then the plasma generator inlet (18) is applied with 0 ~ 400 volts power supply (1), and spray it into the plasma reactor (7) at a speed of 50-80m / s to generate a plasma arc (25), forming a thermal plasma field (28) at 3000°C-8000°C; followed by the natural gas pipe ( After the natural gas in 16) and the pulverized coal gas flow in the pulverized coal flow pipe (15) are preheated through the preheating heat exchanger (14), the 20~ The coal powder of 100 μm is sprayed into the thermal plasma field (28) in the plasma reactor (7) with the speed of 4~6m / s and the amount of coal of 50~90g / min to react, and the acetylene mixed gas generated is in the quencher ( In 9), it is rapidly cooled to 300°C-600°C by the water jet (27) of the quencher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com