Joinery board and production thereof

A blockboard and plank technology, which is applied in the direction of wood layered products, wood processing equipment, and the joining of wooden veneers, can solve the problem of not being able to observe the quality of the core board and damaging the legitimate rights and interests of consumers, and the grade of quality Large difference and other problems, to achieve the effect of simple structure, low manufacturing cost and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

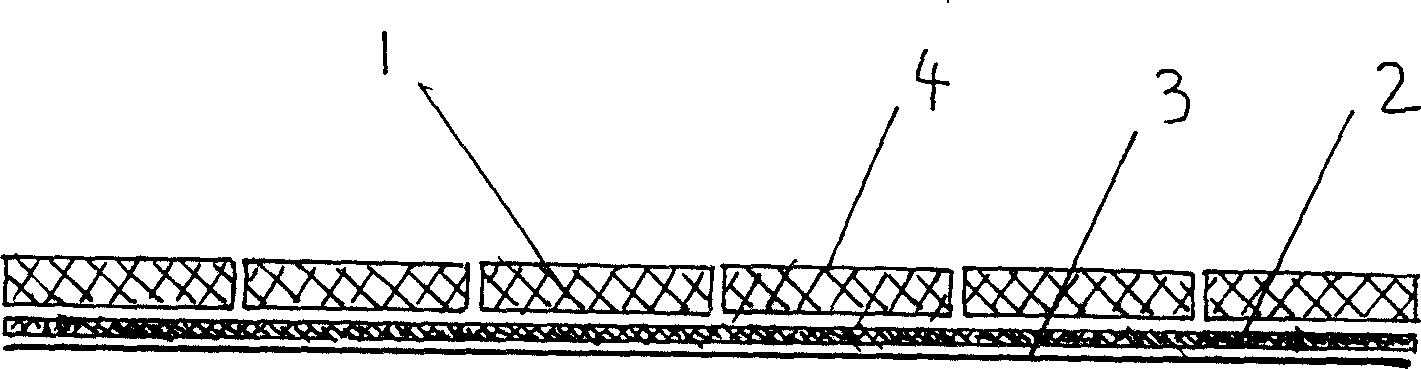

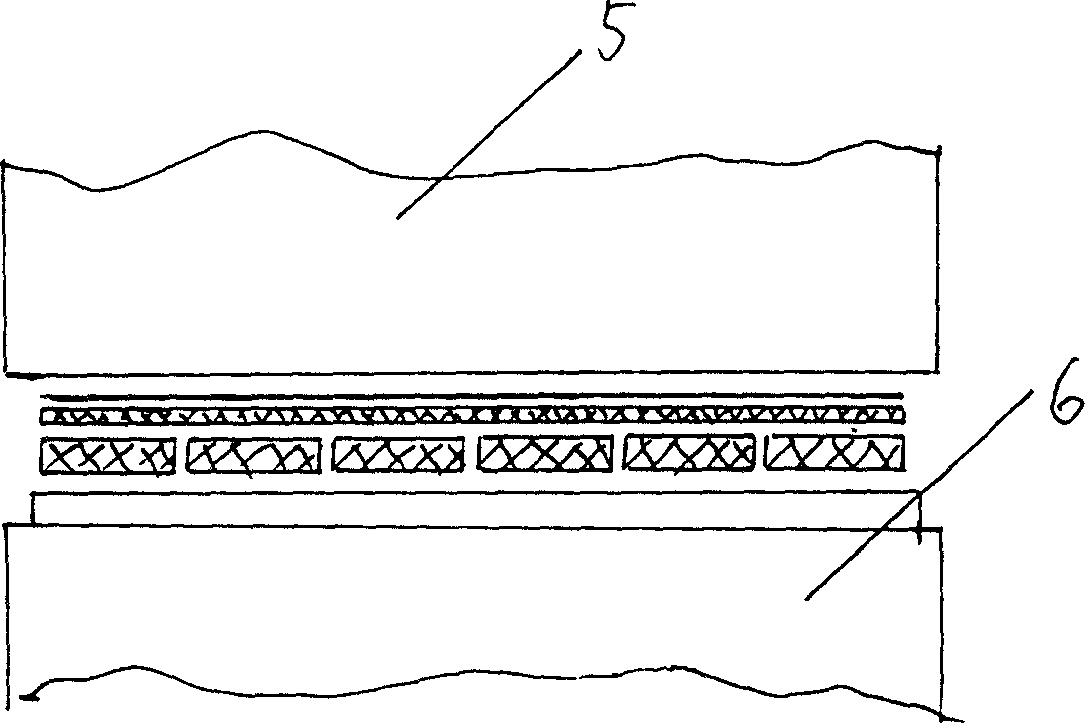

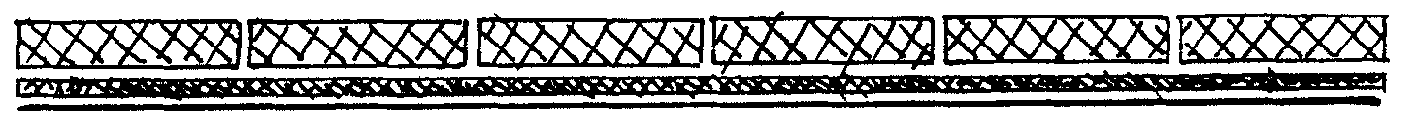

[0014] The invention will be described in detail below in conjunction with the drawings: figure 1 As shown, the present invention mainly consists of a wood core board 1 which is formed by splicing multiple wood boards or other fiber boards. This splicing can be a wedge-shaped splicing, for example, the teeth are joined together, that is, the teeth are connected to each other and then thermally solidified to increase the splicing fastness between adjacent wood core boards. A layer of oak skin 2 is glued on one side of the wood core board, and a layer skin 3 is glued on the oak skin 2. The other side of the wood core board 1 is made into a smooth plane 4. In the actual use process, generally only one side of the wood core board needs to be pasted with the top laminate. Therefore, processing the blockboard into a veneer laminate has special meaning and special finishing effect, which is beneficial to popularization and application. The above-mentioned single veneer blockboard is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com