Light-assisted detection device applied to graphite flake double-edge-covering production equipment

A production equipment and auxiliary detection technology, which can be used in measuring devices, testing moving boards, and material analysis by optical means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

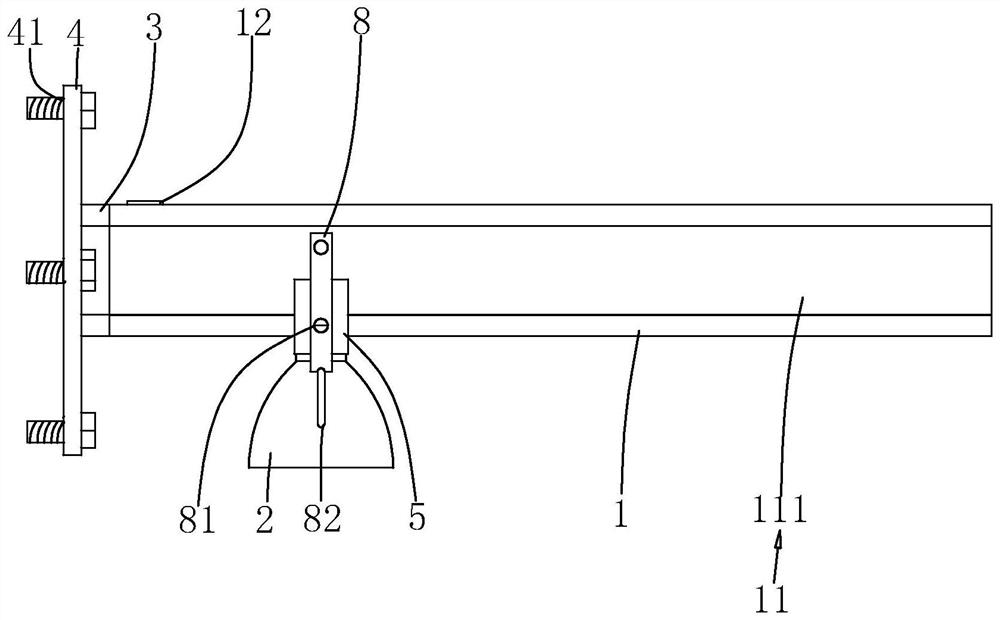

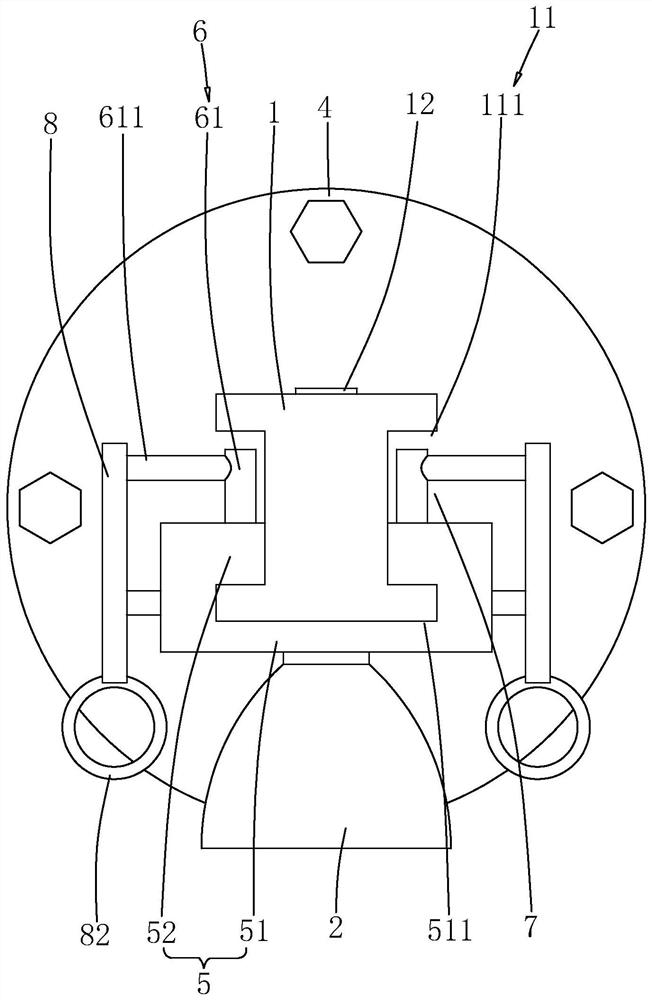

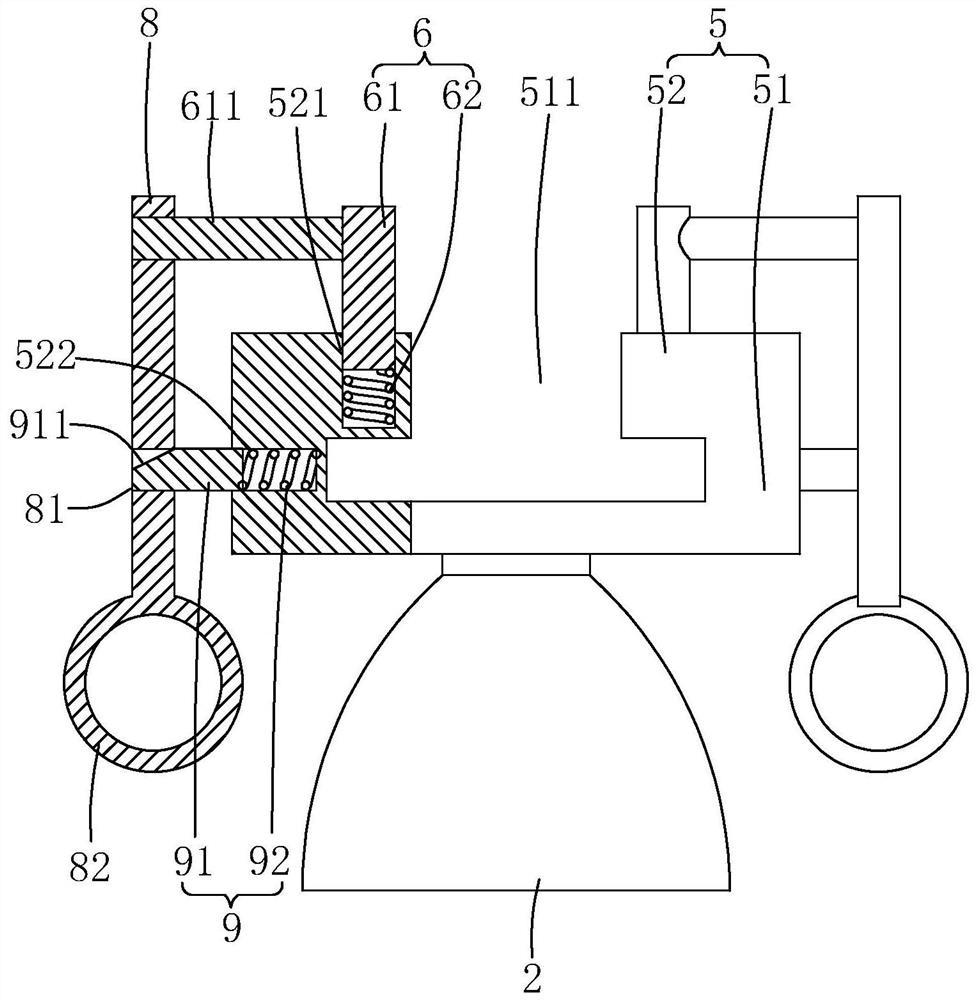

[0046] The following is attached Figure 1-3 The application is described in further detail.

[0047] The embodiment of the present application discloses a light-assisted detection device applied to graphite sheet double-edging production equipment. It is installed on the feeding side of the rewinding drum in the production equipment of graphite flake double edging, and is used to irradiate the material belt so that the staff can observe the quality of the material belt in a well-lit environment.

[0048] refer to figure 1 , The lighting auxiliary detection device includes a lamp holder 1 , a supplementary light 2 and an electromagnet 3 . A soft light is selected as the supplementary light, and the supplementary light 2 is installed on the lamp holder 1 . The electromagnet can be installed on external equipment, and the electromagnet 3 can also be installed on the lamp holder 1 at the same time.

[0049] When the electromagnet 3 is installed to the external device, the lam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com