Self-adsorption air foam-based foam dust suspension system for tunneling machine

A technology of air foaming and roadheading machines, which is applied in the fields of slitting machinery, earthwork drilling and mining, etc. It can solve the problems of reducing system stability, reliability, low foam utilization rate, and increasing system complexity, so as to improve the efficiency of foam dust reduction , simple structure, and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

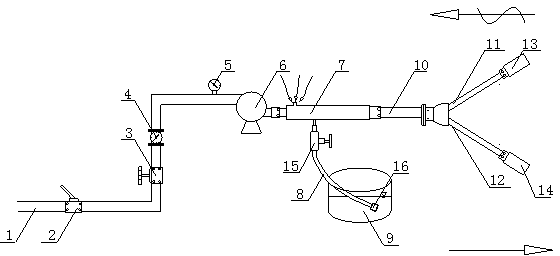

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

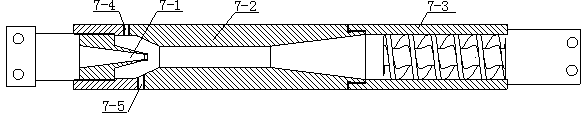

[0013] Such as figure 1 As shown, the present invention is based on self-suction air foaming roadheader foam dust suppression system, which is mainly composed of pressurized water pipeline 1, switch ball valve 2, flow regulating valve 3, mechanical flow meter 4, shock-resistant pressure gauge 5, air-driven liquid pressurization The pump 6 and the self-priming air swirl foaming device 7 are composed; the pressure water pipe 1 is connected to the water supply pipeline extending to the platform of the roadheader body through the quick plug joint, and the switch ball valve 2, the flow regulating valve 3, the mechanical flow rate Meter 4, shock-resistant pressure gauge 5, and gas-driven liquid booster pump 6 are sequentially arranged on the pressure water pipeline 1, and a self-priming air swirl foaming device 7 is provided at the outlet of the gas-driven liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com