Automatic oil-way control system for vehicle-mounted methanol catalytic cracking device

An automatic control system and catalytic cracking technology, which is applied in the direction of charging system, engine control, electrical control, etc., can solve the problems of insignificant tail emission reduction, high cost, and reduced combustion speed, and achieve a wide range of normal operating temperatures and manufacturing The effect of low cost and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

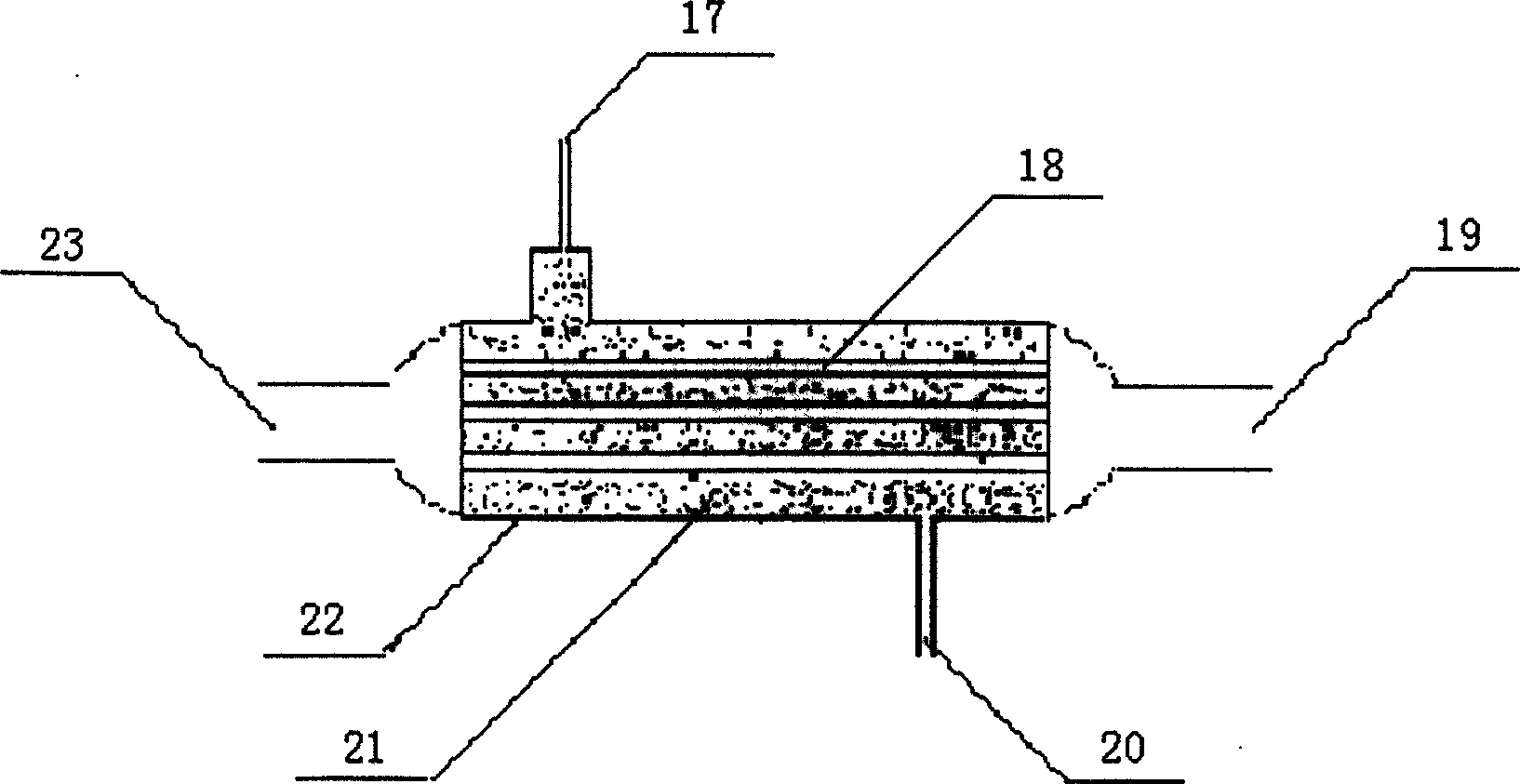

[0027] Methanol enters the catalytic cracking device 4 from the methanol inlet 17 under the action of the methanol pump 2. The main body of the cracking device 4 is a cylinder 22. The methanol inlet 17 is welded on the main body 22. The main body 22 is made of stainless steel. Thin copper tubes 18 placed in parallel, the tail gas is discharged from the tail gas outlet 19 after passing through the copper tube 18 through the tail gas inlet 23, realizing preheating methanol, the gap between the steel body and the thin tubes is filled with a catalyst 21, the catalyst used in this experiment is The copper-based methanol cracking catalyst has an operating temperature of 200° C. to 450° C., and the cracked hydrogen-rich gas is fed into the engine 11 through the cracked gas outlet 20 welded on the main body 22 .

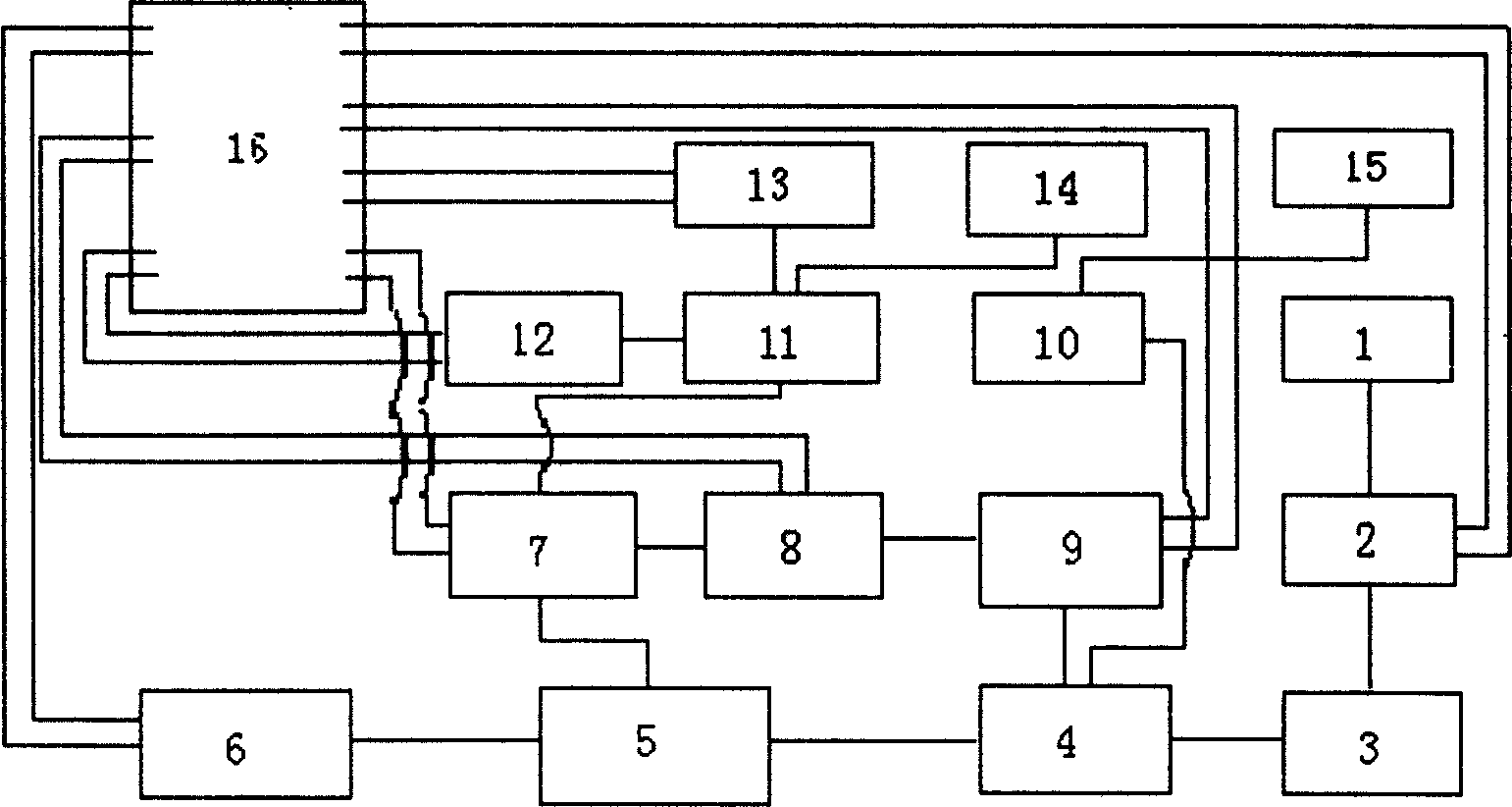

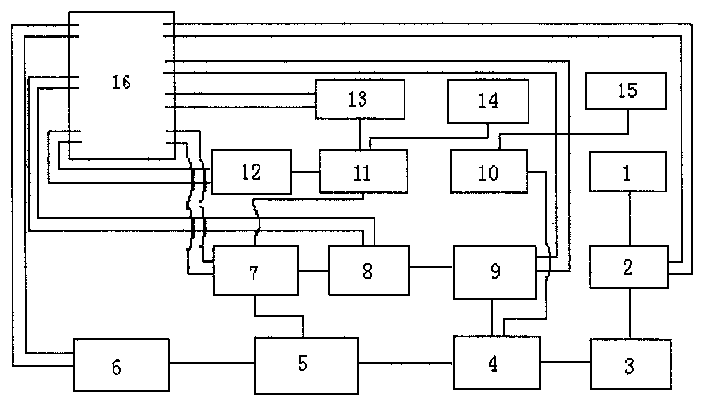

[0028] 1) The energy required by the automatic control system is supplied by the battery of the engine, and the sensors required by the automatic control system include a tem...

Embodiment 2

[0038] Carry out the test under the state of no-load of the engine, adjust the flow rate of methanol to 18ml / min, and the pump oil pressure of fuel pump 2 to 3.5kg / cm 2 , the gas pressure in the gas storage tank 5 is 3.0 kg / cm 2 , the temperature T=273 ℃ of cracking device 4, the weight ratio of fuel oil and cracked gas is 13: 1 all the other are the same as embodiment 1. Use the FLUX4005 exhaust gas analyzer to test the emission composition, and the test results are listed in Table 3:

[0039] Table three

[0040]

Embodiment 3

[0042] Carry out the test under the state of no-load of the engine, adjust the flow rate of methanol to 20ml / min, and the pump oil pressure of fuel pump 2 to 4.6kg / cm 2 , the gas pressure in the gas storage tank 5 is 3.8 kg / cm 2 , the temperature T=364 ℃ of cracking device 4, the weight ratio of fuel oil and cracked gas is 17: 1 and all the other are the same as embodiment 1. Use the FLUX4005 exhaust gas analyzer to test the emission composition, and the test results are listed in Table 4:

[0043] Table four

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com