Improved buffer carrier and supporter

A technology of carrier and track, applied in the field of transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

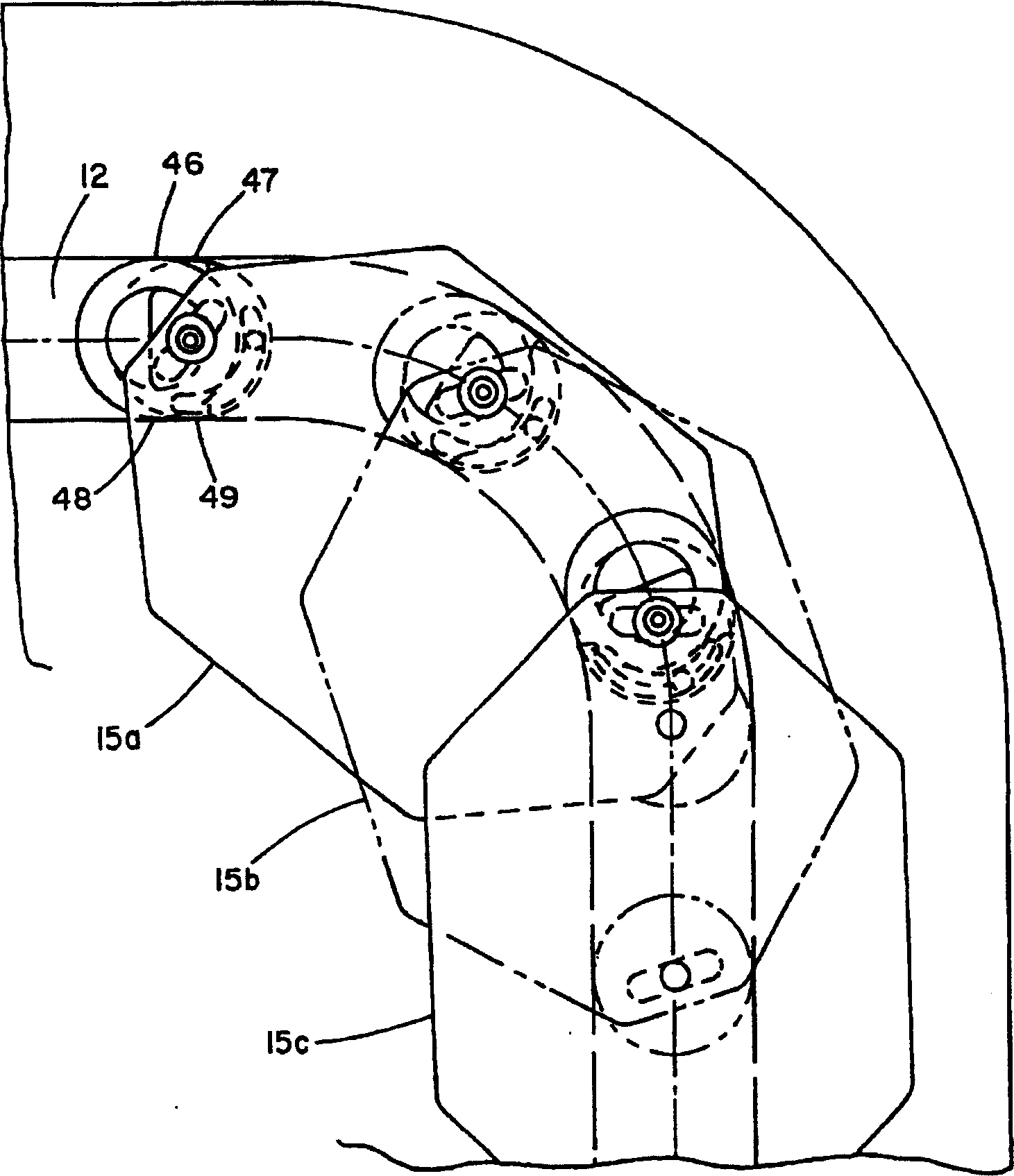

[0034] In the drawings, the same reference numerals are used to designate similar parts.

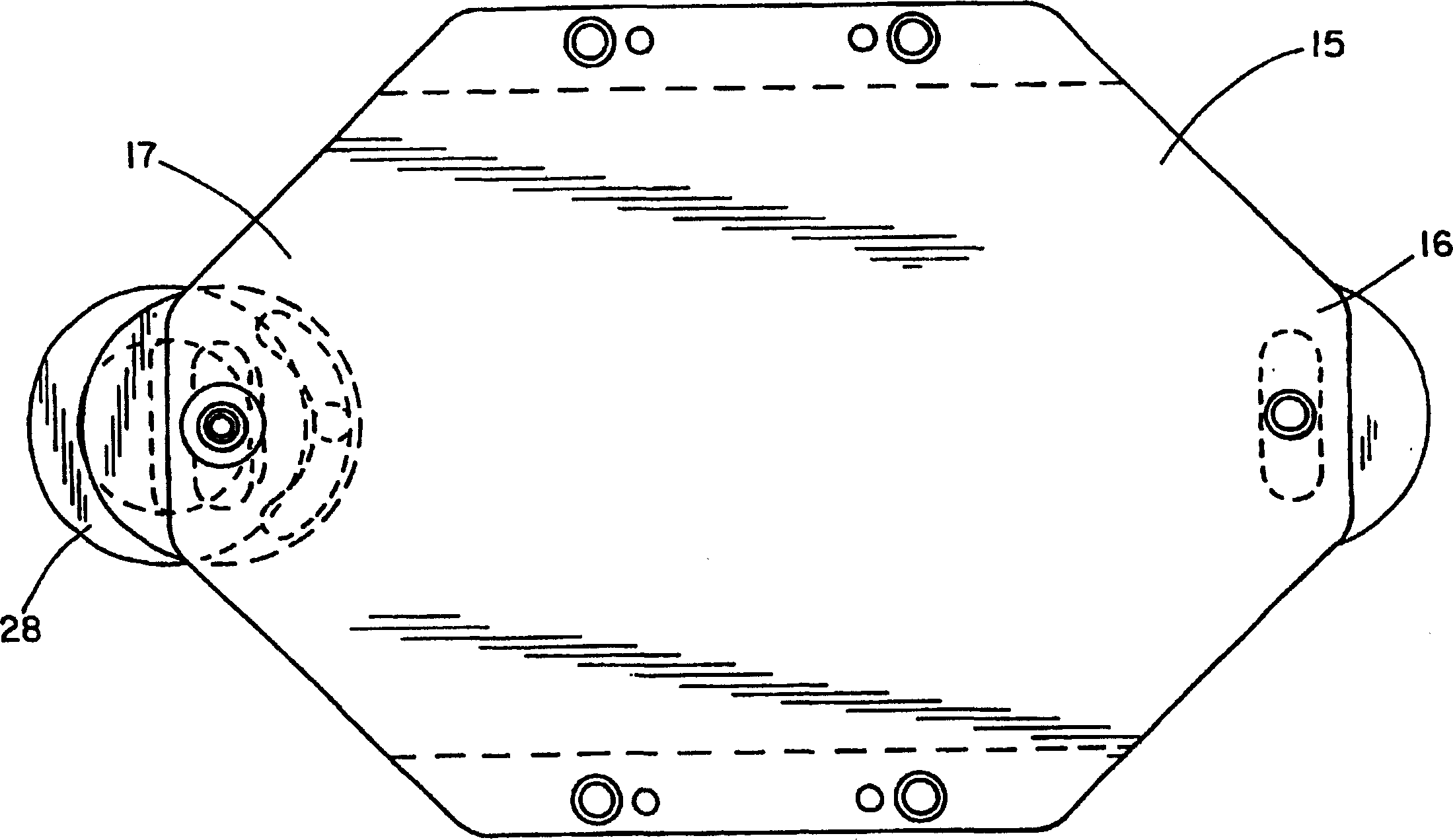

[0035] figure 1 A top view of a pallet 15 equipped with a bumper of the invention is shown. The pallet 15 has a front end 16 and a rear end 17 . A loop 28 extends rearwardly from the rear carrier guide 22 connected to the rear end 17 . Ring 28 is supported within bumper support 24 . An upper plate 26 is interposed between the bumper support 24 and the carrier plate 15 . Along with bumper supports 24 and rings 28 , upper plate 26 includes rear carrier guide 22 . Front carrier guide 21 is of conventional construction and includes a slide plate 20 . A front carrier guide 21 and a rear carrier guide 22 are connected to the underside of the pallet 15 .

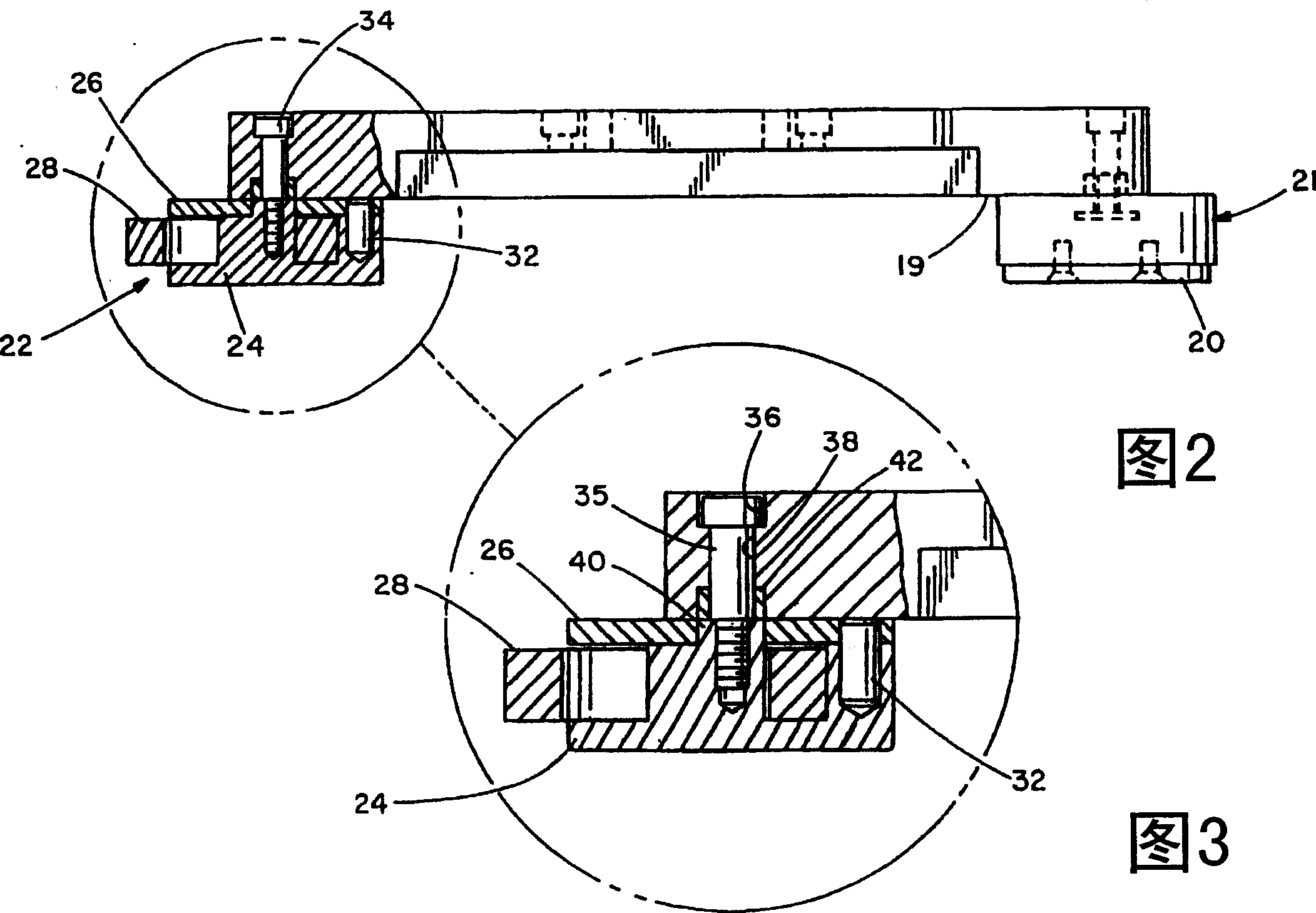

[0036] As shown in FIGS. 2 and 3 , the bumper support 24 is loaded with a pin 32 that is driven into a slot formed in the upper surface of the bumper support 24 . Ring 28 and carrier support 24 are rotatable relative to upper plate 26 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com