Garbage incinerator integrating fluidized incineration and moving cold slag into one integral and method

A waste incinerator, cold slag technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of endangering the safe operation of the fluidized bed boiler, no energy contribution in the combustion process, and affecting the continuous operation of the incinerator, etc. The slag is convenient, the manufacture is simple, and the effect of simplifying the waste pretreatment system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

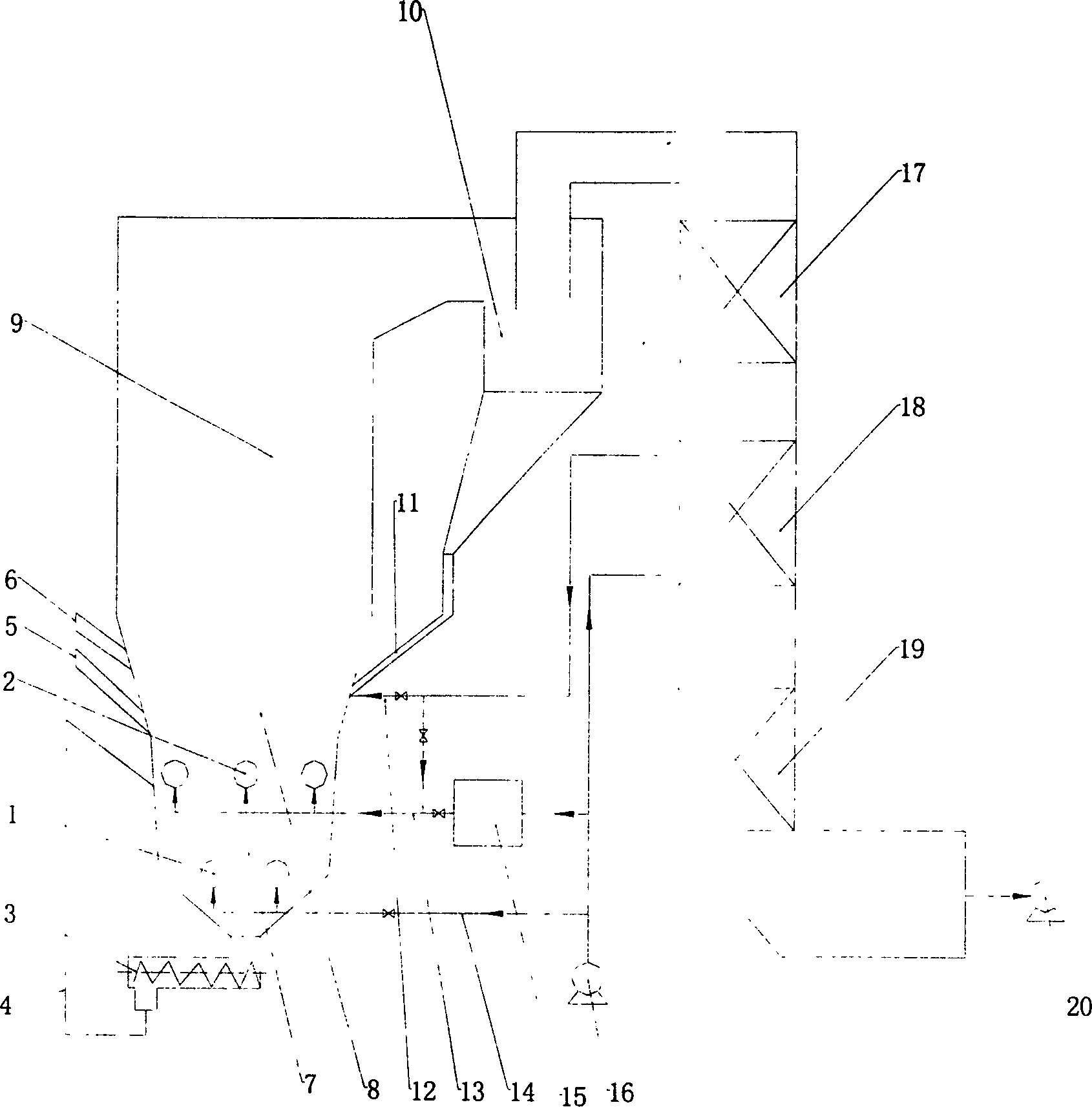

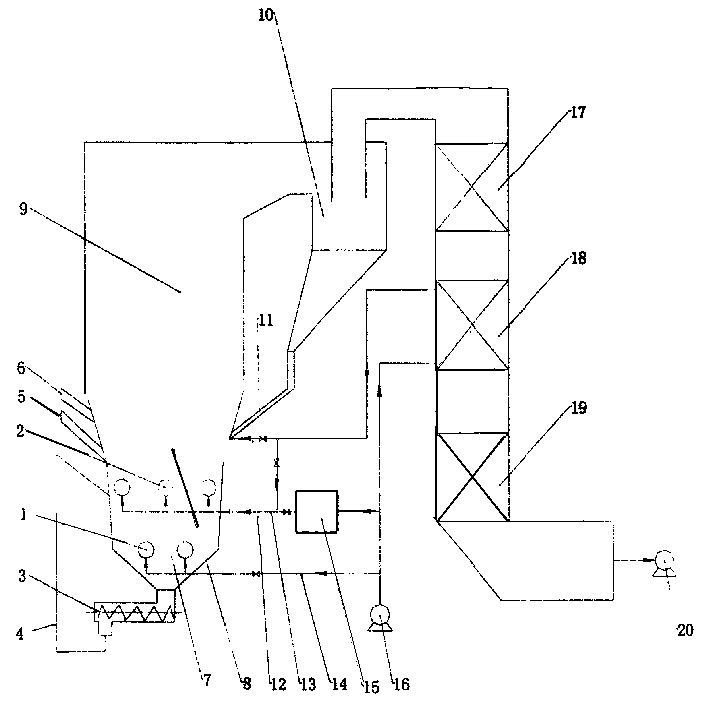

[0010] The waste incinerator integrating fluidized incineration and moving cold slag has a furnace. The furnace is divided into a mobile cooling zone 7, a fluidized zone 8, and a dilute phase zone 9. Pipe 1, slag discharge screening machine 3, fine sand lifting and feeding device 4, a separator 10 is provided at the outlet of the furnace, the separator is connected to a return device 11, the lower end of the return device is connected to the furnace fluidized zone, and the separator outlet is connected to the furnace in turn Superheater 17, air preheater 18, economizer 19, induced draft fan 20, coal feeder 5, waste feeder 6, blower 16, cold primary air duct 14, lower air distribution duct 1 The air blower 16 is connected with the igniter 15, the primary air duct 13, and the upper air distribution pipe 2, the lower end of the air preheater 18 is connected with the blower 16, the outlet of the air preheater 18 is connected with the secondary air duct 12, and the return device 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com