Quantitative characteristic testing method for strain frozen of PVC profile material

A polyvinyl chloride, characterization testing technology, applied in the field of characterization testing of physical and chemical parameters, can solve problems such as unsure and effective control of low temperature drop punching, and achieve the effect of solving the quality fluctuation of profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

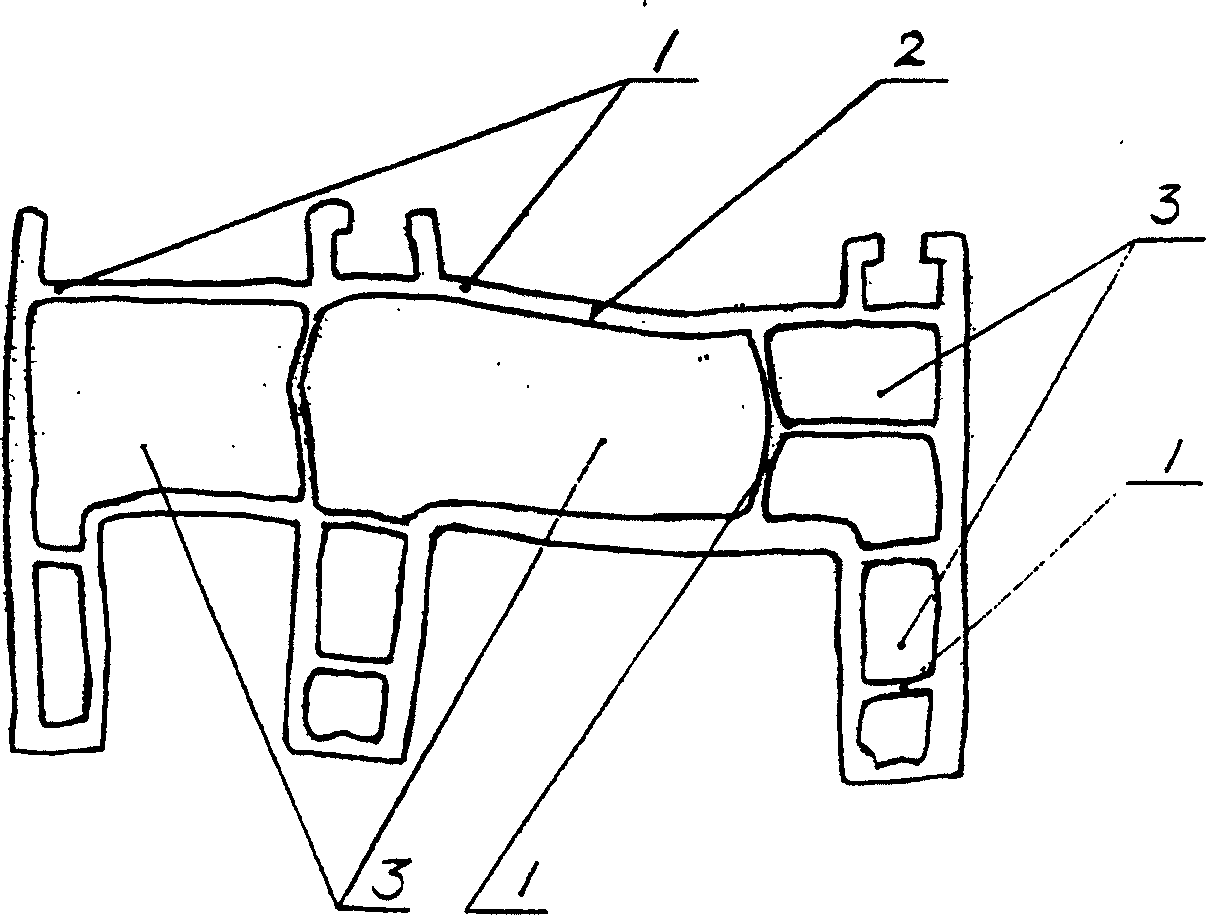

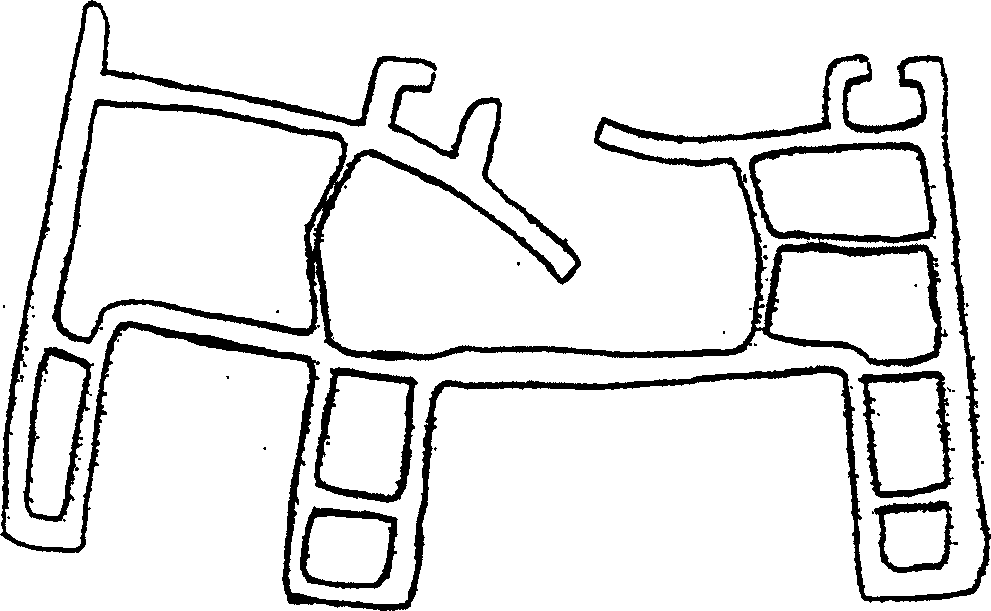

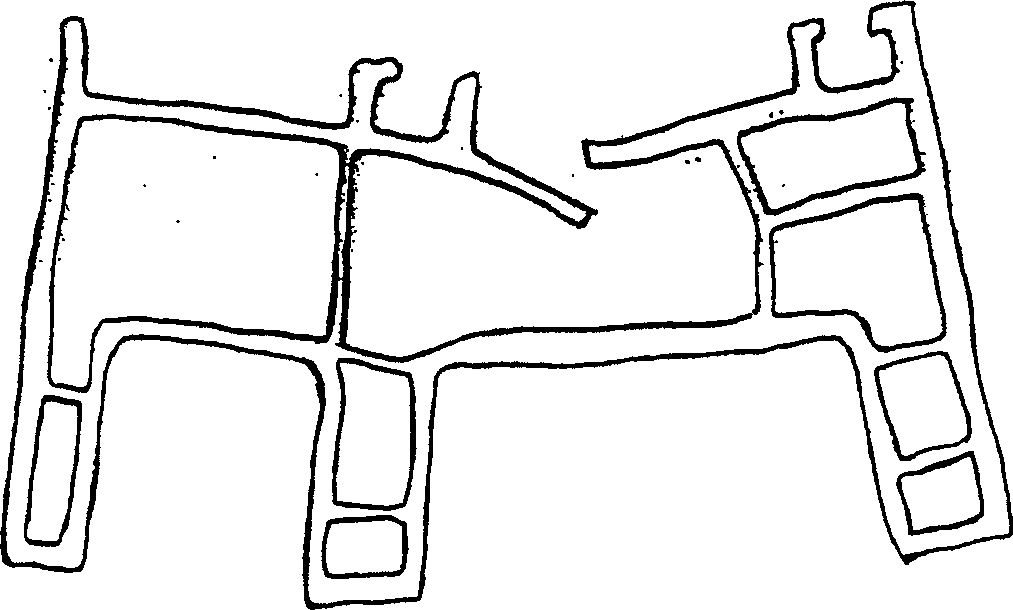

Image

Examples

Embodiment 1

[0045] Polyvinyl chloride profile formula:

[0046] PVC (K=68, No. 2 Beijing Chemical Factory) 100 parts by weight

[0047] Active light calcium carbonate (average particle size 5-10 μm, commercially available) 10 parts by weight

[0048] Titanium dioxide (rutile type, U.S. DuPont) 4 parts by weight

[0049] Chlorinated polyethylene (Cl content 36% by weight, Shandong Weifang Chemical Factory) 9 parts by weight

[0050] Acrylic ester processing aid (ACR-401, Suzhou Amway Chemical Factory) 2 parts by weight

[0051] Rare earth stabilizer (GKD-200A, Shantou Gao Keda Company) 3.5 parts by weight

[0052] Use the same twin-screw extruder according to the above formula and the same extrusion temperature to produce two batches of profiles A and B. The above-mentioned profile strain freezing test method is used to test two batches respectively, in which the thickness of the sample is 4.0±0.1mm, and a single incision is taken in the middle of the frame of the main chamber. Then c...

Embodiment 2

[0056] Except that the heat treatment temperature is 150° C., all the other conditions are the same as in Example 1. The test results are shown in Table 2.

[0057] Example 2-A

[0058] From the results measured in Examples 1 and 2, it can be seen that the heat treatment temperature is 150°C and 180°C, and the deformation is basically similar. Because the sample has far exceeded the glass transition temperature (80°C) of polyvinyl chloride at 150°C, the movement of its macromolecules, chain segments, and crystallites has reached a fully saturated level. Therefore, even if the heat treatment temperature is increased to 180 °C, the deformation amount of the sample does not change significantly.

Embodiment 3

[0060] Polyvinyl chloride profile formula:

[0061] PVC (with embodiment 1) 100 parts by weight

[0062] Active light calcium carbonate (average particle size 1-12 μm, commercially available) 9 parts by weight

[0063] Titanium dioxide (with embodiment 1) 4 parts by weight

[0064] Chlorinated polyethylene (with embodiment 1) 10 parts by weight

[0065] Acrylic ester processing aid (same as embodiment 1) 2.5 parts by weight

[0066] Rare earth stabilizer (with embodiment 1) 3.5 parts by weight

[0067] Using the same twin-screw extruder according to the above recipe, two batches of profiles C and D were produced. The body temperature of the two groups of batches is 150-175°C during extrusion, and the temperature of the head and mold is different. The temperature of the extrusion head and mold of batch C is 180-196°C, and the temperature of extrusion head and mold of batch D is 2-5°C lower than that of batch C.

[0068] Strain freeze tests were performed on the above two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com