Cooling board

A cooling plate and cooling pipe technology, which is applied in liquid distribution, packaging, heat exchange equipment, etc., can solve the problems of cooling pipe heat exchange efficiency reduction, high-quality product rate decline, and low yield, so as to improve heat exchange efficiency and fully The effect of cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

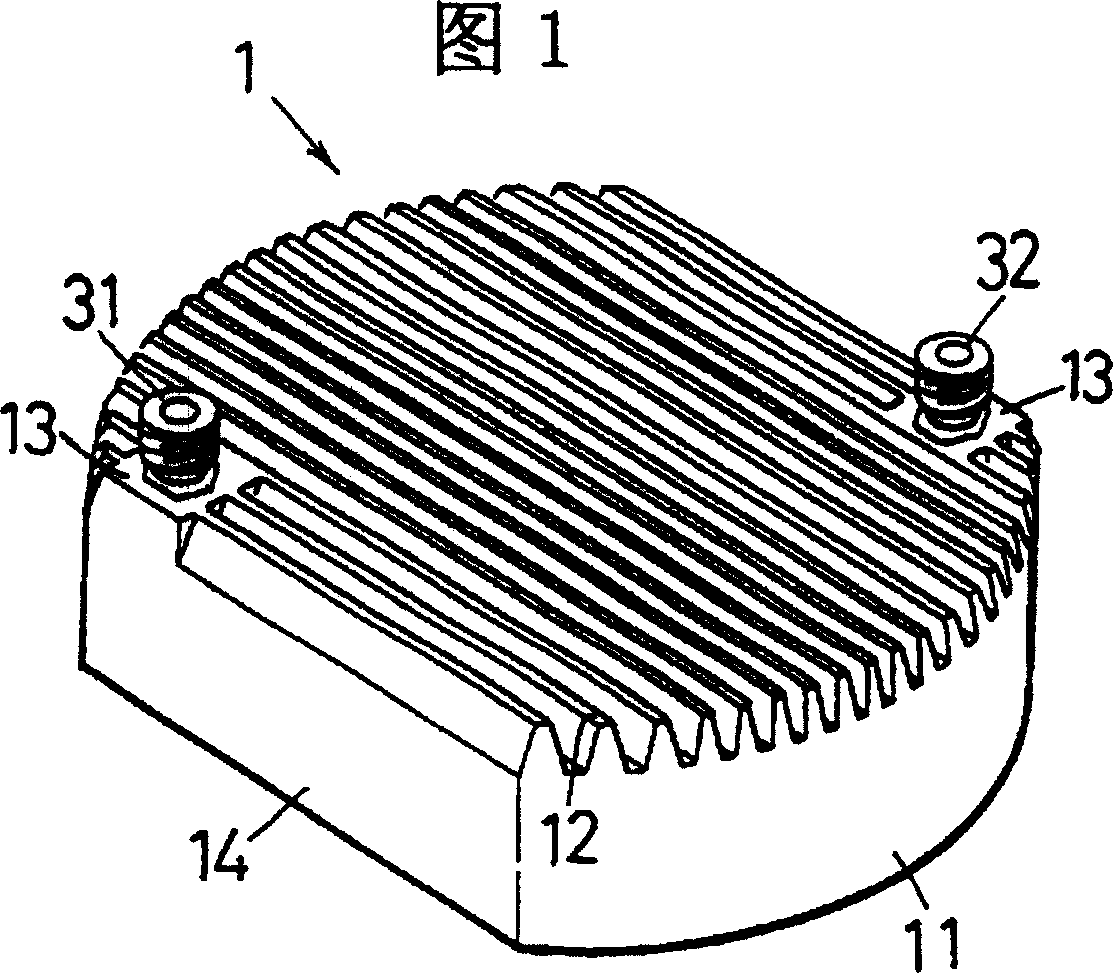

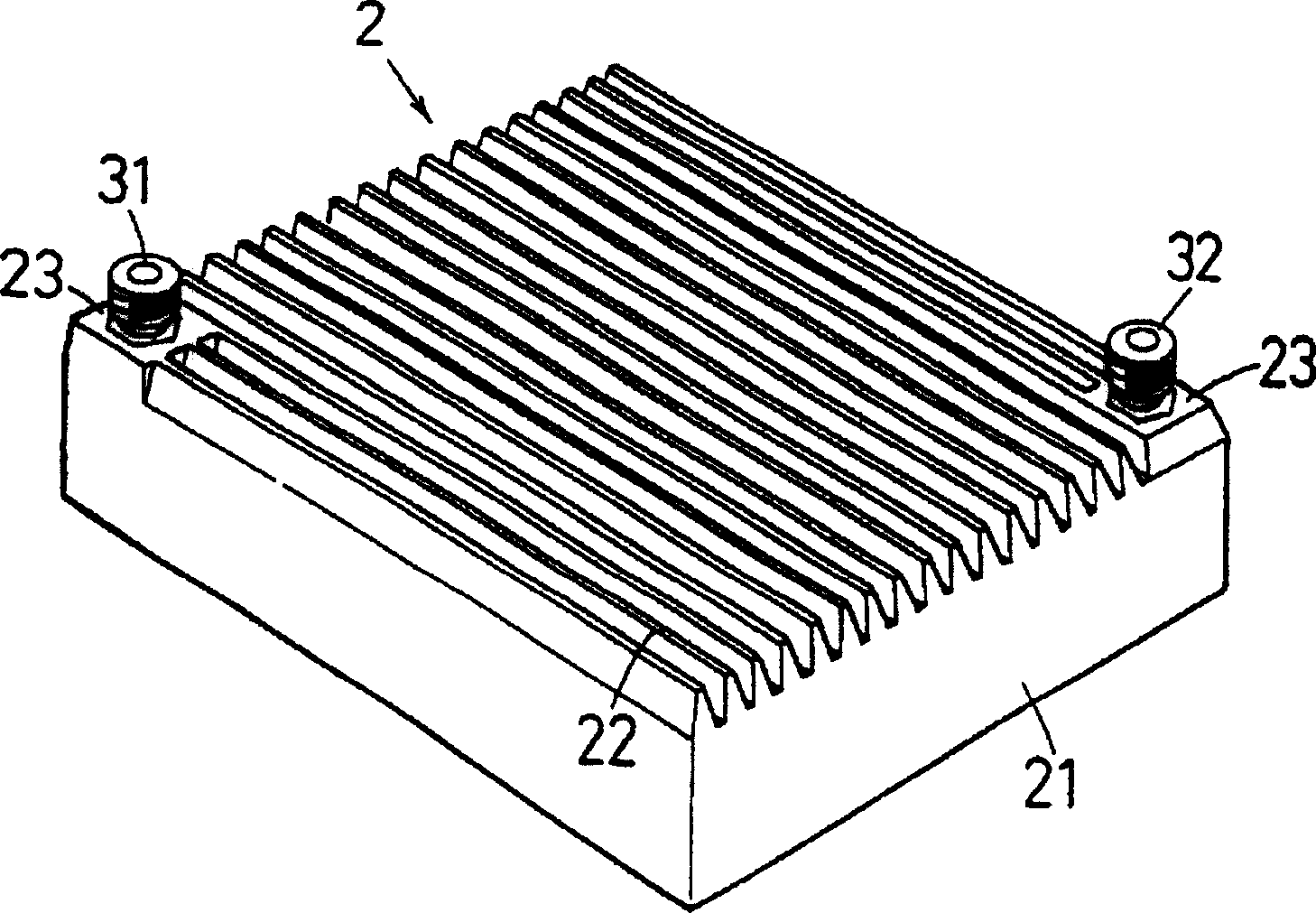

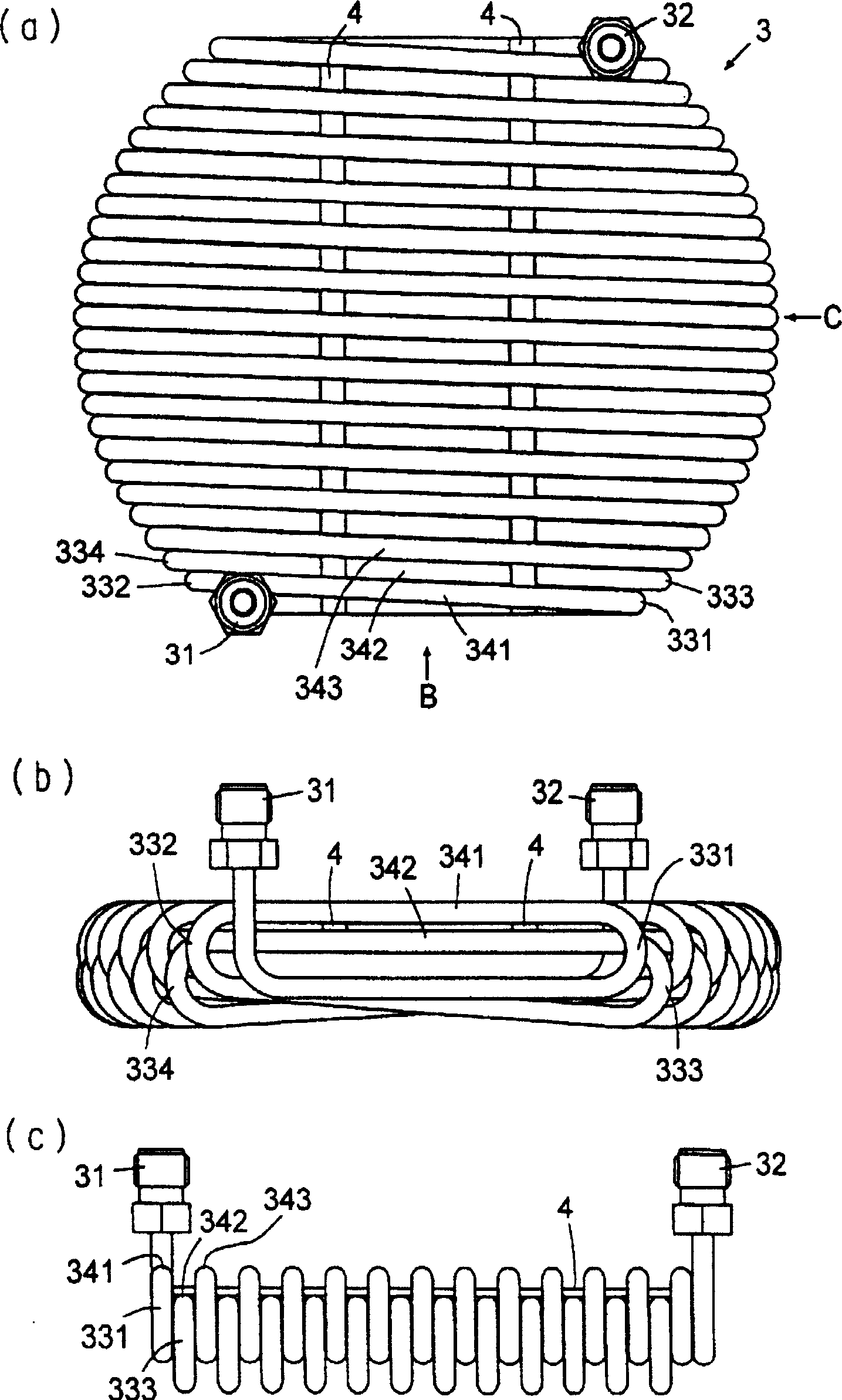

[0031] Embodiments of the present invention will be described below with reference to the drawings. Here, the beverage is taken as draft beer, and the beverage container is taken as a beer keg, and this will be described as an example. 1 and 2 are perspective views showing the appearance of cooling plates 1 and 2 of the present invention. Figure 1 shows a circular cooling plate. The plate main body 11 of the cooling plate 1 is substantially in the shape of a circular plate, and two flat outer peripheral planar portions 14 are formed at two positions facing each other on the circumference. When the cooling plate 1 is placed in a substantially cylindrical cooling container, the two outer peripheral flat parts 14 can be arranged so as to be easily grasped by hand. And when the cooling plate 1 is taken out from the cooling container, it is also easy to take it out by pinching the outer peripheral flat portion 14 .

[0032] The cooling plate 1 is formed by casting a cooling pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com