Thermal-stacking infrared sensor and mfg. method thereof

An infrared sensor, thermopile technology, applied in instruments, scientific instruments, photometric methods, etc., can solve the problems of unoptimized impurity concentration, reduced S/N ratio, high resistivity, etc., to expand infrared absorption rate or Absorbable wavelength range, excellent S/N ratio, effect of improving S/N ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

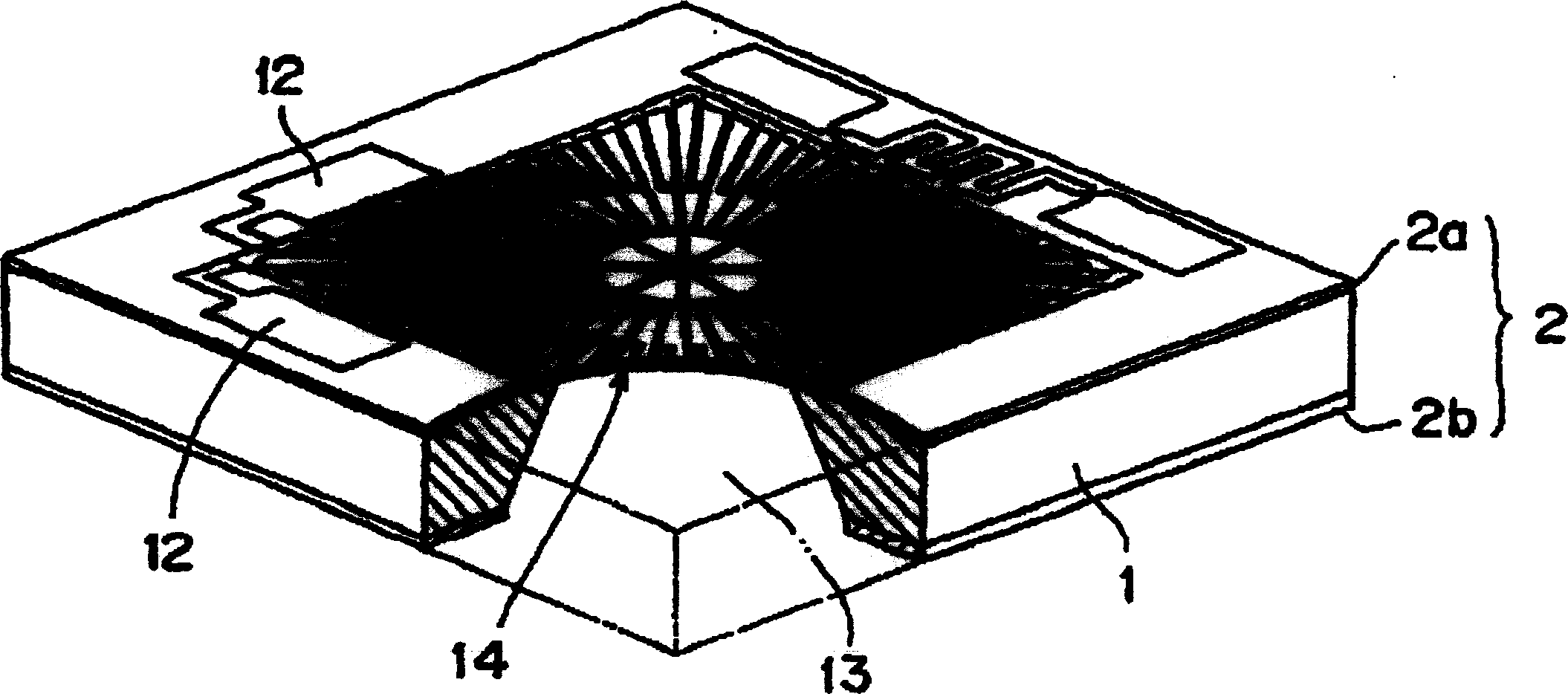

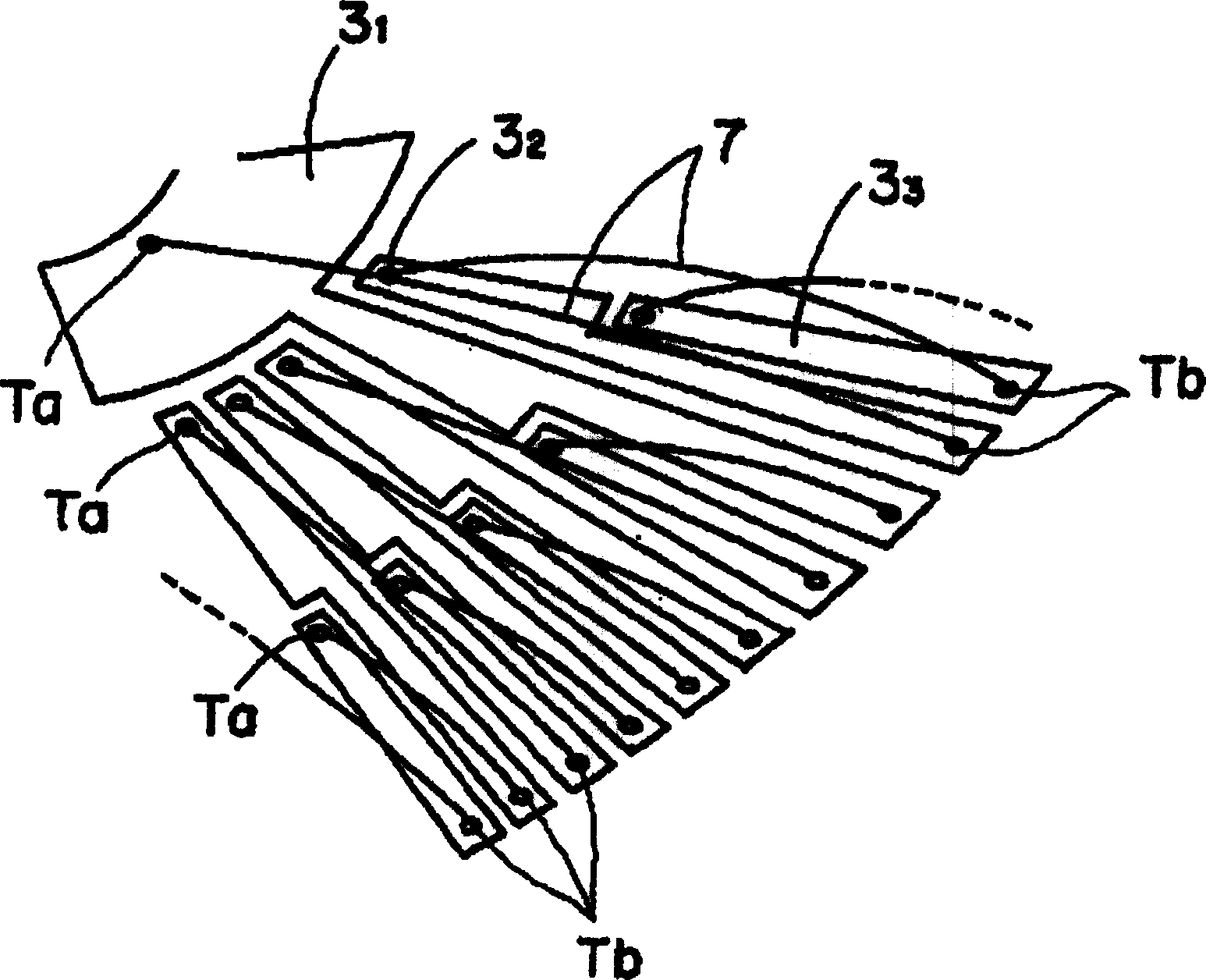

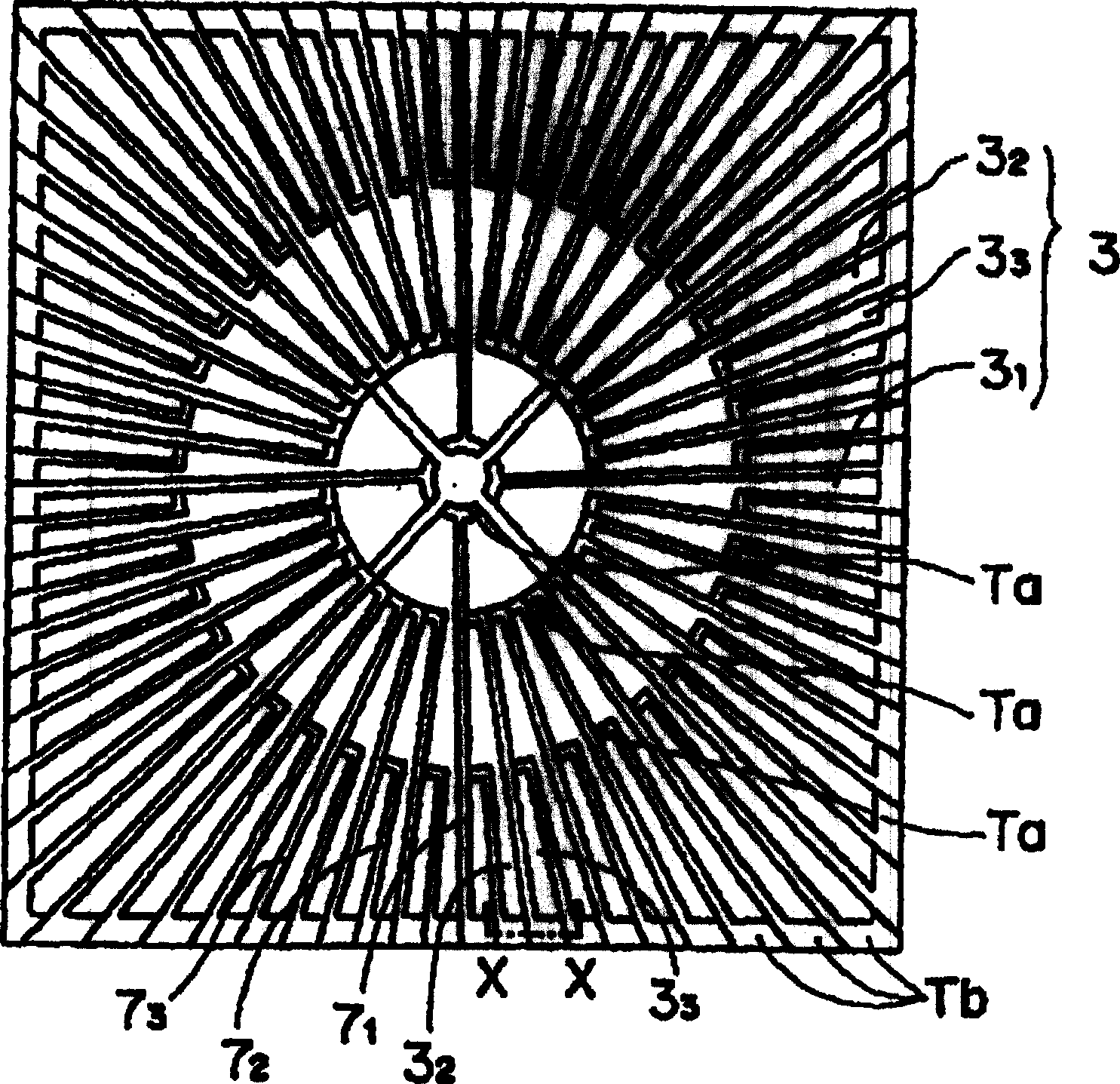

[0180] refer to figure 1 ~ Fig. 6 illustrates Embodiment 1 of the present invention. figure 1 The oblique view of the partial cutout in FIG. 2 shows the thermal pile element (chip) of the thermal pile infrared sensor of the present invention. figure 2 It is an explanatory drawing for explaining the thermal-pile infrared sensor of the present invention. Figure 3(a) is figure 1 The plan view of the polysilicon layer, omits the illustration of the insulating film, passivation film and resin absorbing film, etc., Fig. 3(b) is the X-X sectional view of Fig. 3(a) when the insulating film has been formed. Figure 4 A partial plan view of is showing the outline of the thermal-pile infrared sensor of this embodiment. Figure 5 is the case where the insulating film has been formed Figure 4 Partial floor plans shown in. 6( a ), ( b ) are schematic cross-sectional views of forming a passivation film or an infrared absorption film on a thermopile infrared sensor.

[0181] exist ...

Embodiment 2

[0212] refer to Figure 7 ˜ FIG. 9 illustrates Embodiment 2 of the thermal-pile infrared sensor of the present invention. Figure 7 The schematic diagram shows half of the diagram of a thermopile infrared sensor. Figure 8 It is an enlarged key part schematic showing 1 / 4 of the whole figure. In addition, in Figure 7 , Figure 8 In , the insulating film or passivation layer etc. are omitted. Figure 9(a)~(d) is Figure 8 The film configuration of the A-A, B-B, C-C, and D-D cross-sections shown.

[0213] The purpose of this embodiment is to make the n-type polysilicon layer 3 of embodiment 1 1 ~3 3 The resistance decreases and the S / N ratio is improved, so the film thickness of the n-type polysilicon layer is formed thicker, Figure 7 Its graph is shown. In this embodiment, as in Embodiment 1, a single crystal silicon substrate having a cavity portion is used, and insulating films are formed on both surfaces thereof. As the n-type polysilicon layer of the thermoelectri...

Embodiment 3

[0220] refer to Figure 10 An embodiment of the thermal-pile infrared sensor of the present invention will be described with reference to FIG. 11 . Figure 10 shows the outline of the 1 / 4 figure of this embodiment, and Fig. 11 shows Figure 10 The film composition of A-A, B-B, C-C, D-D, E-E surface. In this example, if Figure 10 , as shown in FIG. 11, adopting the method of disposing the metal thin film layer 7 on the insulating film 2a, it is no longer necessary to cover the patterned n-type polysilicon layer described above with the insulating film 4, and form a polysilicon layer on the insulating film 4. Manufacturing process of the opening portion 15 . Therefore, the manufacturing method of Example 3 is a manufacturing process in which the insulating film 4 forming the opening portion is removed from the manufacturing method of Example 1, and thus detailed description thereof will be omitted.

[0221] exist Figure 10 As in FIG. 11, in this embodiment, on the insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com