Waste-liquid treatment method for straw pulp paper-making

A paper-making sewage and straw pulp technology, applied in the regeneration of lye, etc., can solve the problems of high treatment and operation costs, paper-making enterprises cannot operate normally and stably, and wastewater cannot be discharged stably up to the standard, so as to achieve thorough treatment, low operating costs, and good governance The effect of small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method for straw pulp papermaking sewage treatment of the present invention, comprises the steps:

[0029] ① Feed straw pulp papermaking raw materials into the steaming ball, add sodium sulfite accounting for 13-15% of the weight of straw pulp, formaldehyde accounting for 1.3-1.4% of the weight of straw pulp and anthraquinone accounting for 0.03-0.05% of the weight of straw pulp in the steaming ball , mix them, and heat to 160-175°C, react for 3 hours to make a puree;

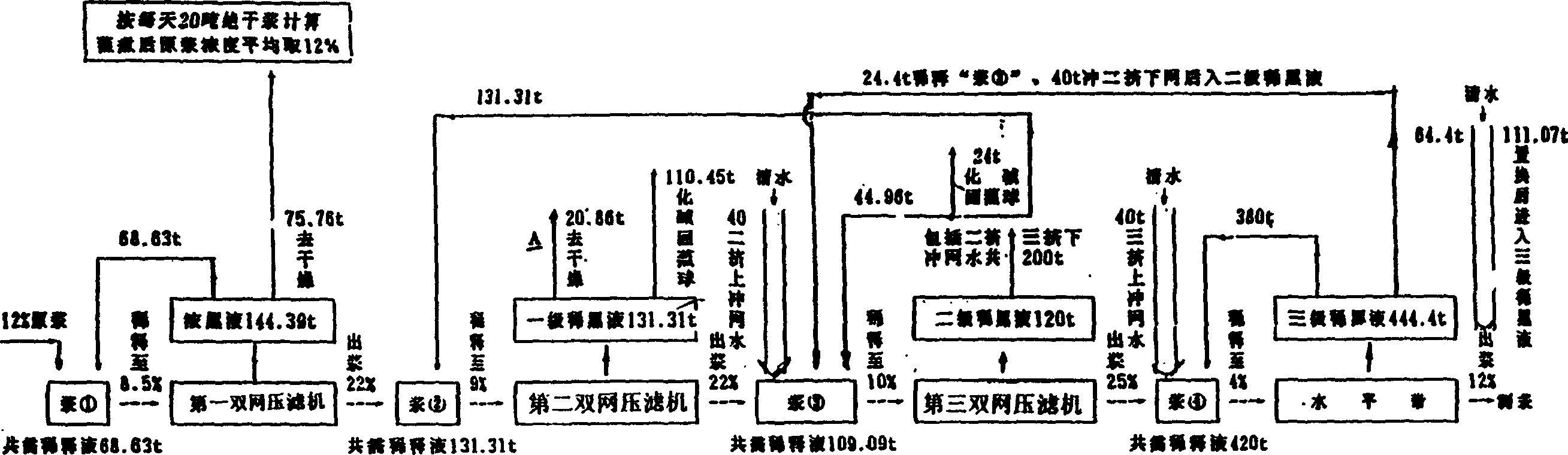

[0030] ② The raw pulp is extracted through extrusion equipment for three times to extract black liquor;

[0031] Dilute the raw pulp sprayed from the steaming ball to 8-9%. After passing through the screener, it is sent to the first black liquor extraction equipment for extrusion. 50-60% of the extruded thick black liquor is sent to dry, and the rest Return to stock for dilution;

[0032] Dilute the slurry from the first black liquor extraction equipment to 8-9%, then pump it into the second black ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com