Long cellosilk high-speed filter

A long-fiber filament and filter technology, applied in the direction of gravity filter, loose filter material filter, filtration separation, etc., can solve the problems of difficulty in effective cleaning, affecting the continuous effect of filtration, and small specific surface area of the filter material. It is convenient for long-term stable operation, easy equipment installation and maintenance, and the effect of prolonging the backwash cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

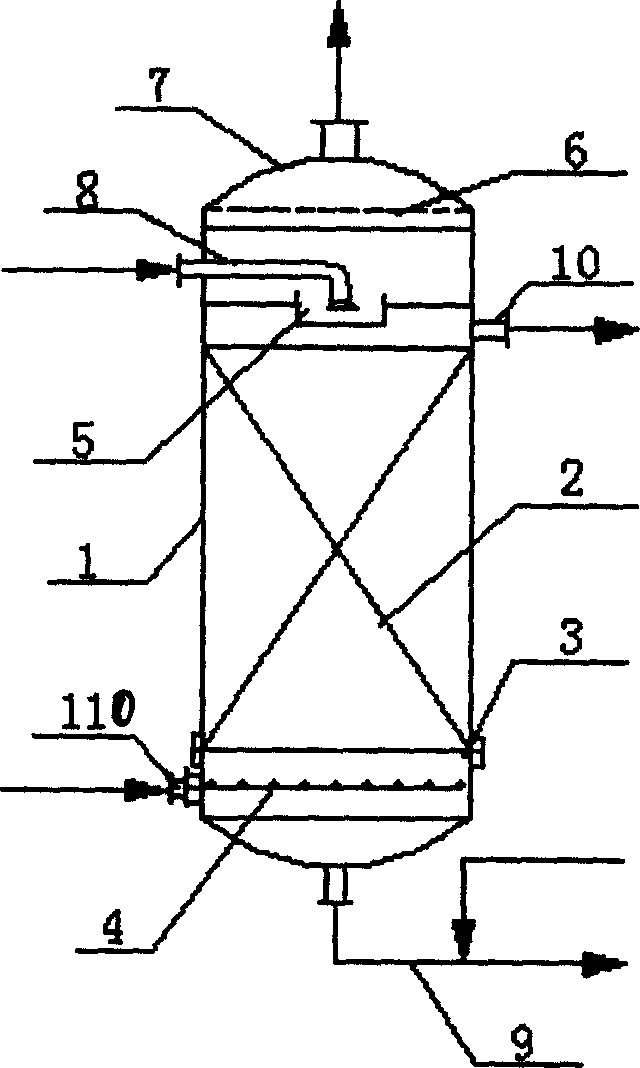

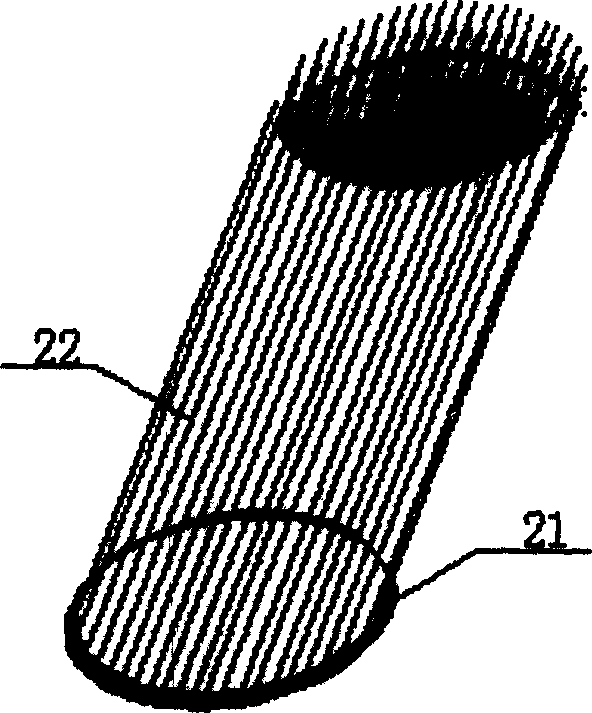

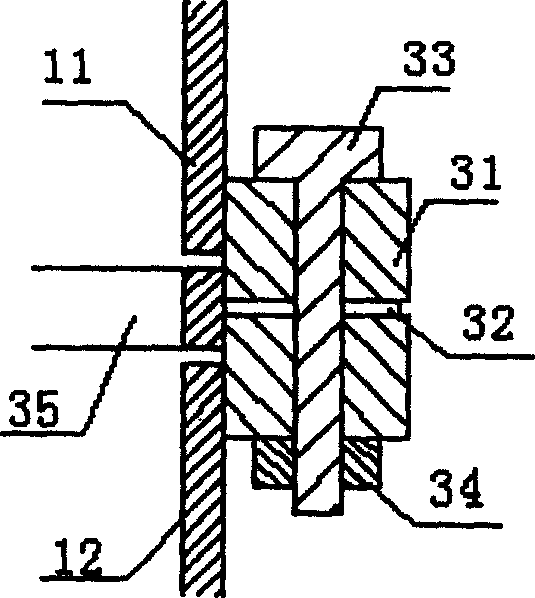

[0021] The long-fiber high-speed filter of the present invention is composed of a filter assembly and external equipment. The filter mainly includes a filter cylinder 1, a long-fiber high-speed filter assembly 2, an embedded flange connection device 3, a direct-connected Ring perforated pipe gas distributor 4, axisymmetric water inlet distributor 5 with central water inlet and peripheral water outlet, grid type gas and water separator 6, etc., wherein long fiber high-speed filter assembly 2 is arranged in filter cylinder 1 , the gas distributor 4 is arranged at the bottom of the long-fiber high-speed filter assembly 2, and the backwash inlet pipe 110 is directly communicated with the gas distributor 4; the filtered water and the backwash water inlet pipe 9 are arranged at the bottom of the lower cylinder 12; 1 The upper part of the inner long fiber filter assembly 2 is provided with a water inlet distributor 5, the water outlet end of the water inlet pipe 8 is located in the ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com