Image sensor single-layer conductor rest secondary semi-etching mfg. method

A technology of image sensor and lead frame, which is applied in semiconductor/solid-state device manufacturing, electric solid-state device, semiconductor device, etc. It can solve the problems that affect the transmission effect of micro-sensing signals, it is not easy to ensure good product quality, and the preparation process is difficult. , to avoid the mechanical stamping production process, the practical effect is ideal, and the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

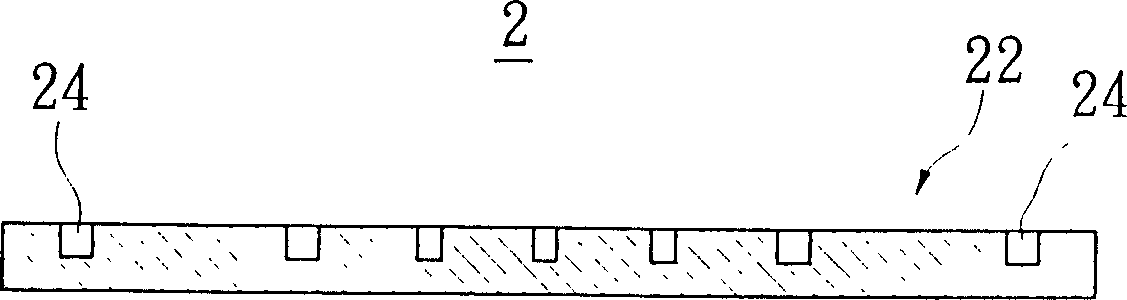

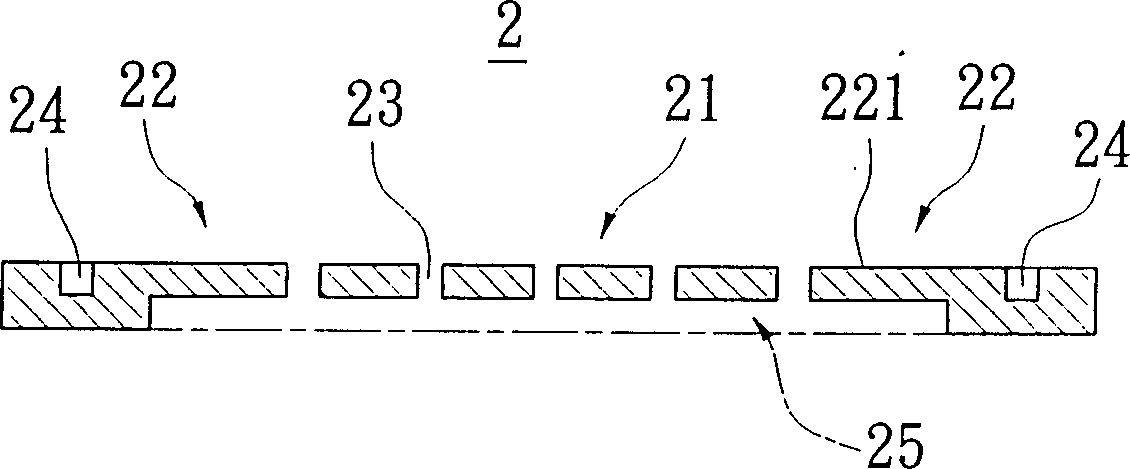

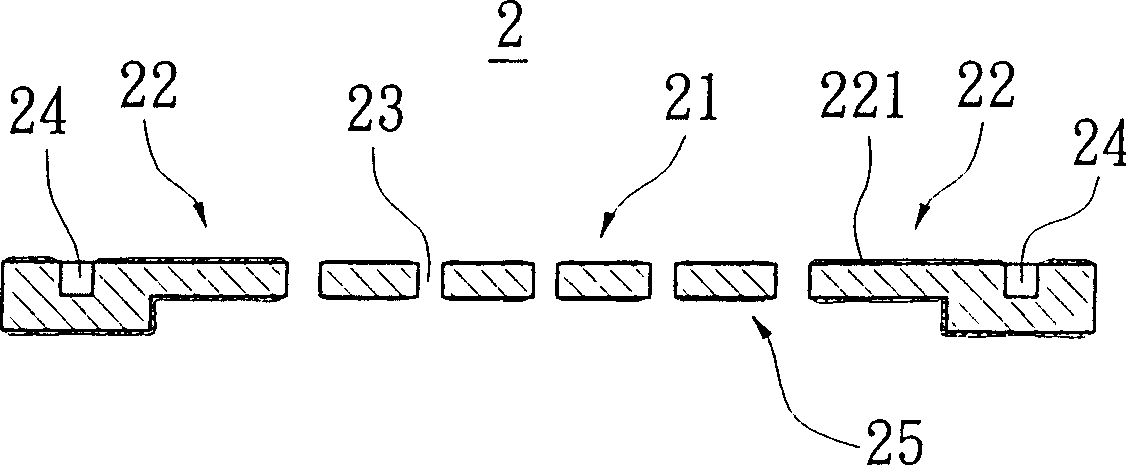

[0025] refer to Figure 1 to Figure 5 As shown, the present invention relates to a second half-etching preparation method of a single-layer lead frame of an image sensor.

[0026] Such as Figure 5 As shown, the structure of the image sensor of the present invention includes: a sensing chip 1, a single-layer lead frame 2 and a glass cover 4; the lead frame is provided with a chip holder 21 and several pins 22, and each pin 22 is surrounded inside The periphery of the chip holder 21 is defined as an inner lead 221, which is used to connect the signal contact of the sensing chip 1, and each lead 22 extends outside to the lower edge of the package to define an outer lead 222, which It is a surface mount technology pin used for soldering an external printed circuit board to transmit electrical signals; the sensing chip 1 is pasted on the top surface of the chip holder 21, and is connected to the top surface of each inner pin 221 with a metal wire 11, so that the sensing chip 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com