Implanting machine in paddy field

A technology for working machines and paddy fields, applied in agricultural machinery and implements, chassis of agricultural implements, agriculture, etc., can solve problems such as rising costs and complicated structures, and achieve cost reduction, sufficient lubricating oil, and restraint oil temperature. rising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, the description of the present invention will be made with reference to the accompanying drawings showing a rice transplanter as an example of a paddy field operation machine.

[0036] Examples will be described.

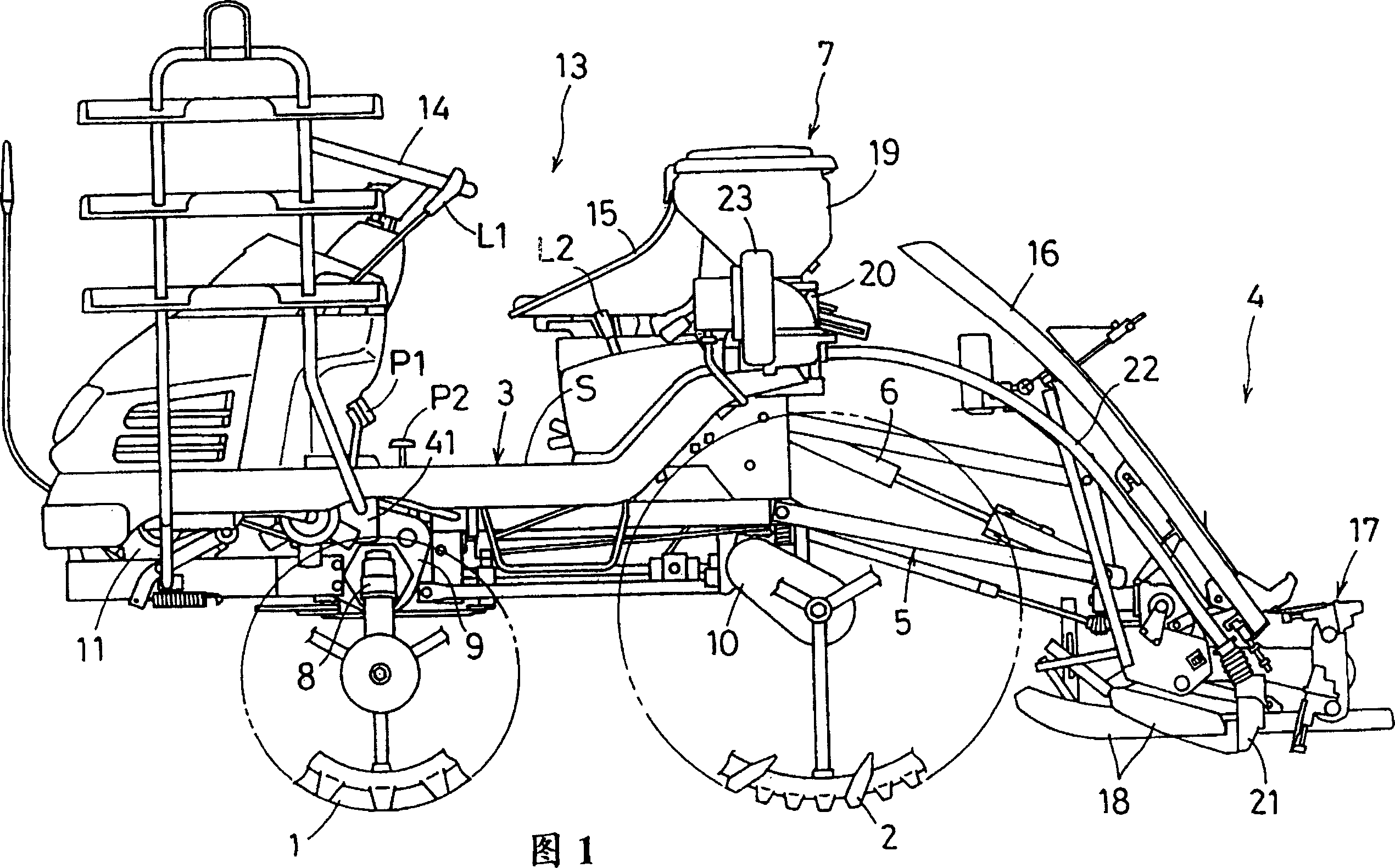

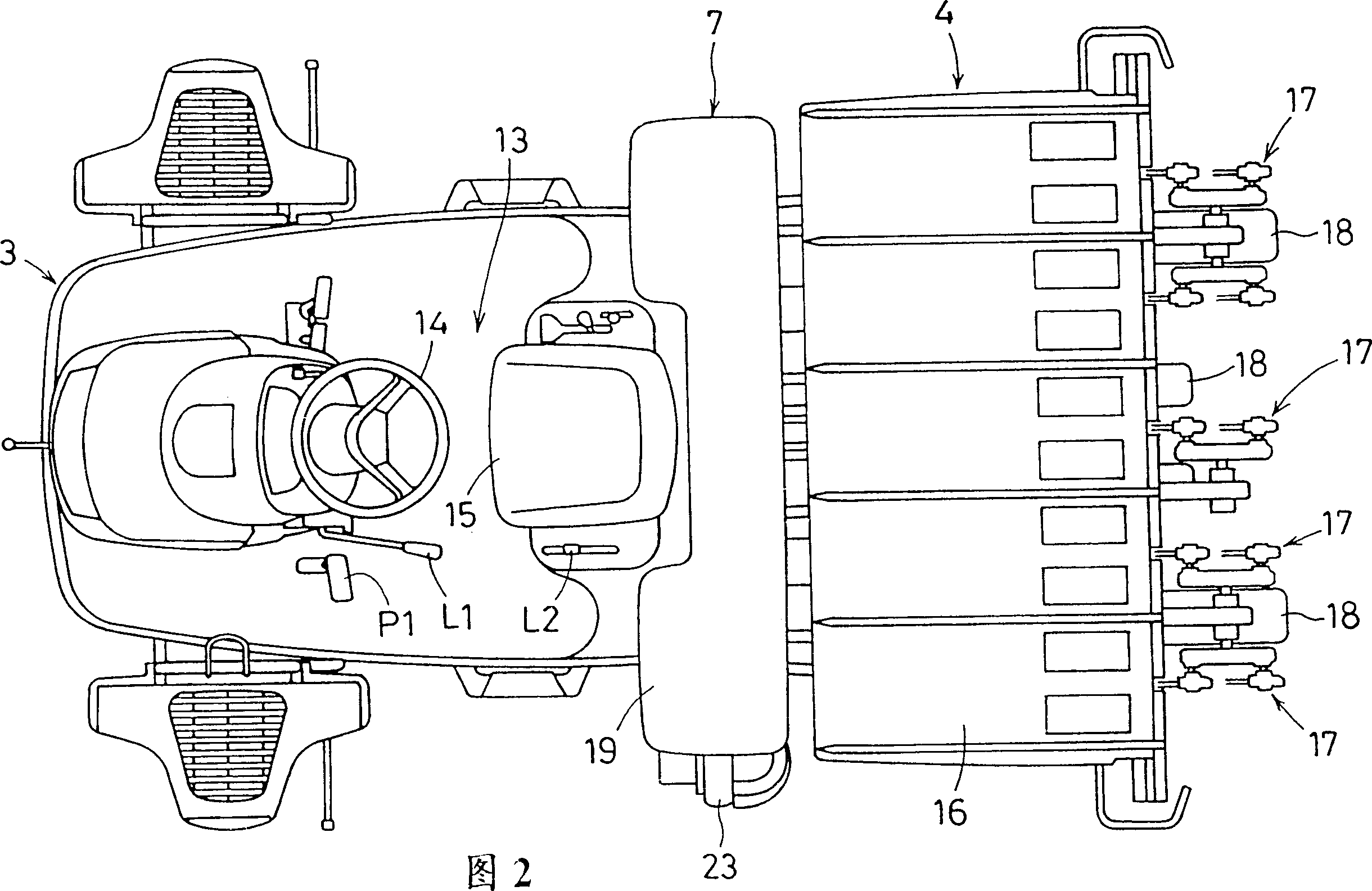

[0037] As shown in Figure 1 and Figure 2, this rice transplanter has a left and right pair of driving front wheels (equivalent to front wheels) 1 and a left and right pair of driving rear wheels (equivalent to rear wheels) 2. The rear part of the planting device 4 is connected with a multi-row planting type planting device 4 as an example of a paddy field operation device through a four-bar linkage 5. It is also provided with a lifting hydraulic cylinder 6 and a fertilizing device that utilizes an oil cylinder to lift the planting device 4. 7.

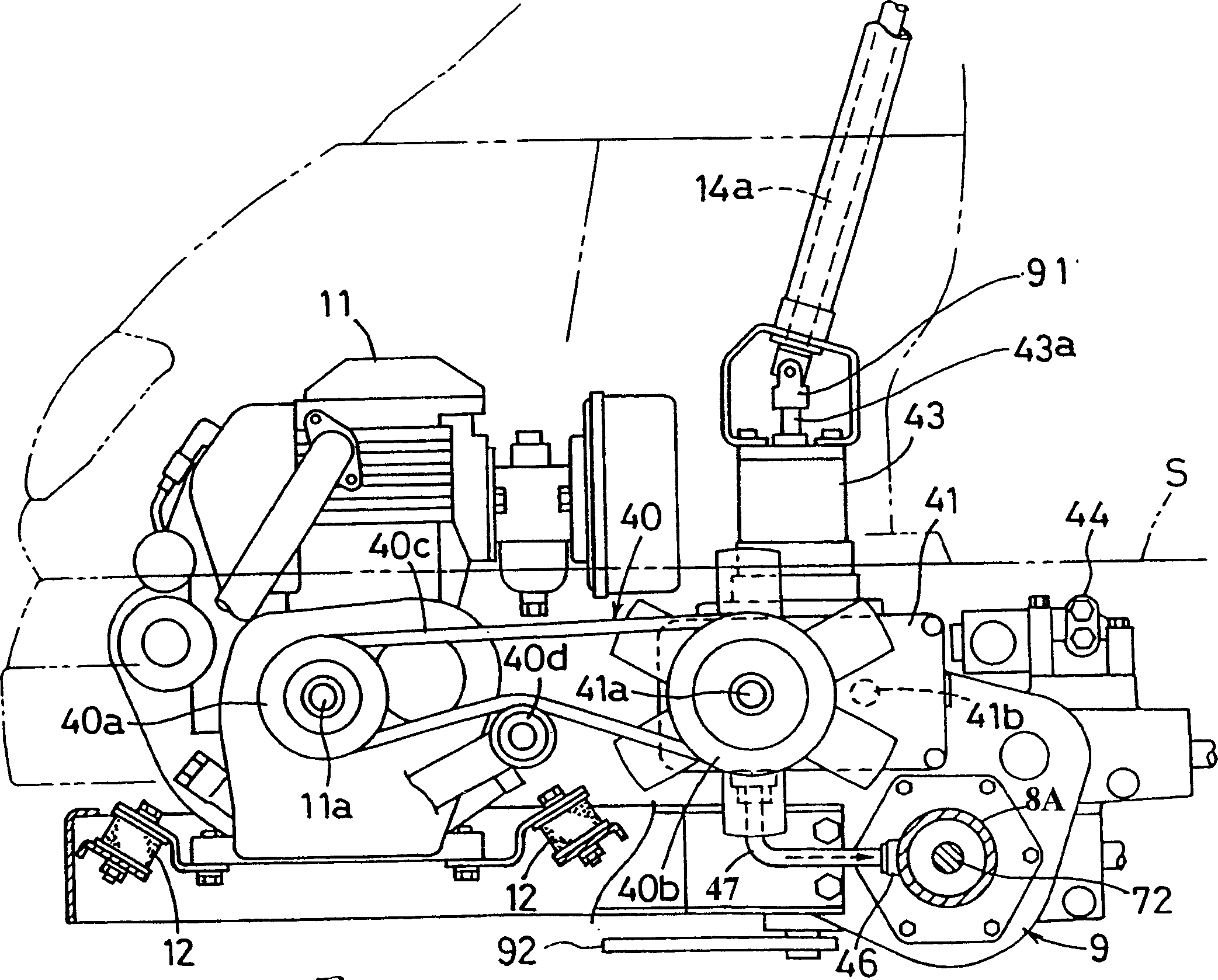

[0038] self-propelled body 3 as image 3 , Figure 4 As shown, there is a gearbox 9 that drives the front wheels 1 through the front axle box 8. At the same time, in the body frame that drives the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com