Hydraulic pressure supply device for industrial vehicle

A technology for hydraulic supply and industrial use, applied in transmission, fluid transmission, transmission control, etc., can solve the problem of not effectively suppressing the rise of oil temperature, oil temperature rise, etc., and achieve the effect of suppressing the rise of oil temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

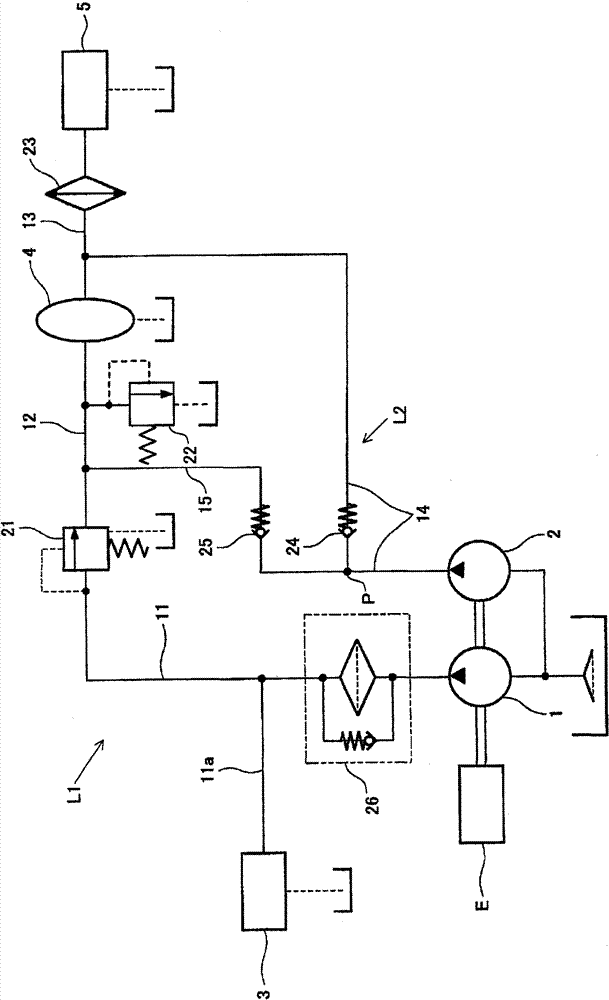

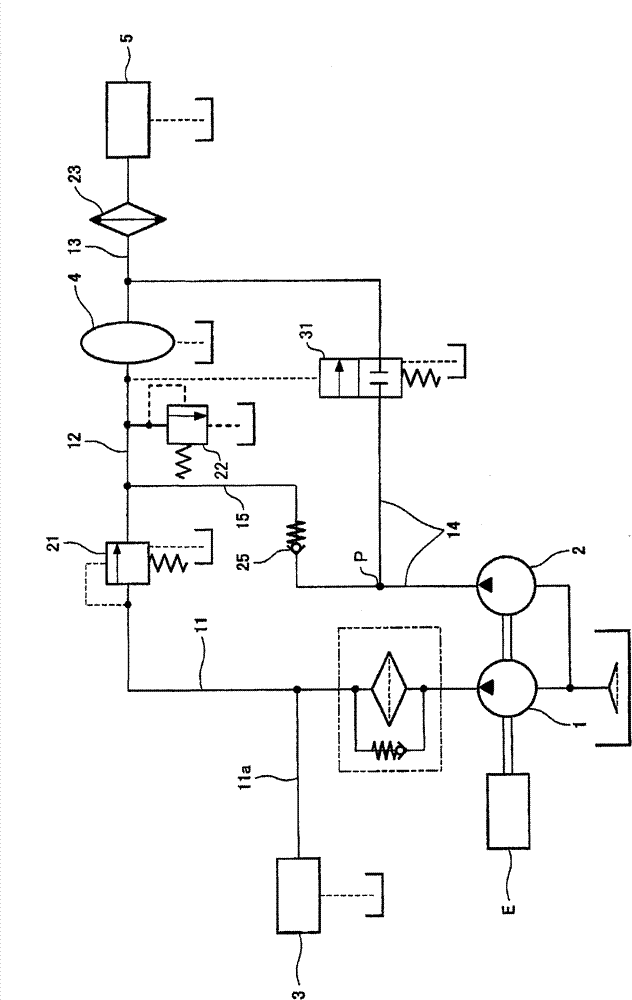

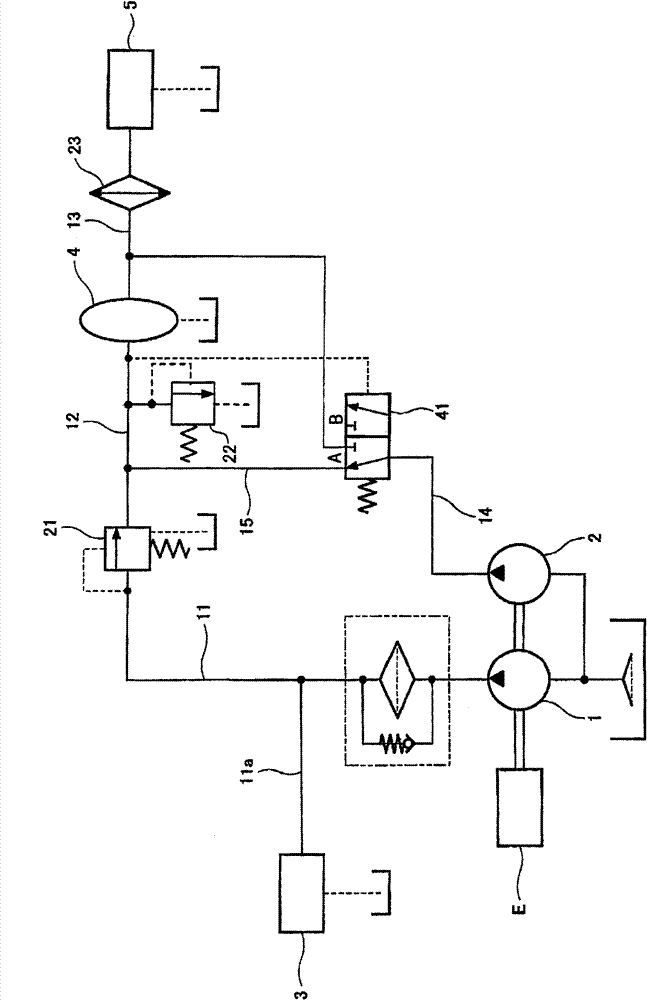

[0019] Hereinafter, a hydraulic pressure supply device for an industrial vehicle according to an embodiment of the present invention will be described with reference to the drawings.

[0020] Figure 4 It is a side view of a wheel loader which is an example of an industrial vehicle to which the hydraulic pressure supply device in this embodiment is applied. The wheel loader 100 is composed of a front body 110 having an arm 111 , a bucket 112 , tires 113 and the like, and a rear body 120 having a cab 121 , an engine compartment 122 , tires 123 and the like. The arm 111 is rotated vertically (pitching) by the drive of the arm hydraulic cylinder 114 , and the bucket 112 is rotated vertically by the drive of the bucket hydraulic cylinder 115 (unloading or loading). The front body 110 and the rear body 120 are rotatably connected to each other by a center pin 101 , and the front body 110 bends left and right relative to the rear body 120 by extending and contracting a steering cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com