Method and device for static sensitization of emulsion explosives

An emulsified explosive, static technology, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of long initial sensitization time, easy blockage and shutdown, complex device structure, etc., to achieve easy workshop process layout and strong production matching ability , Easy to install, disassemble and wash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

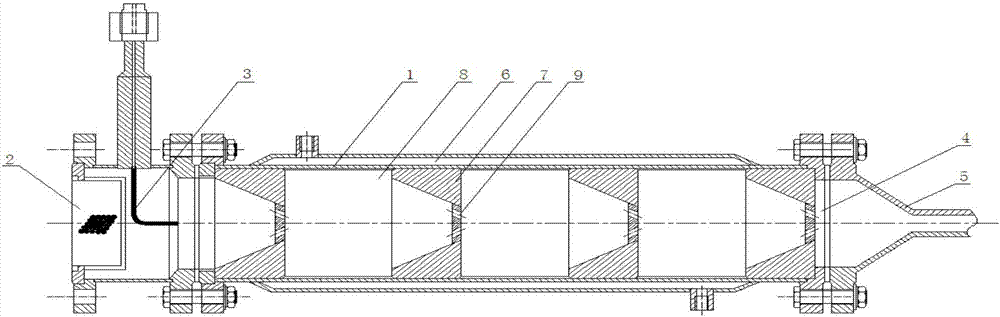

[0053] Attached below figure 1 The present invention will be further described in detail with specific embodiments. as the picture shows:

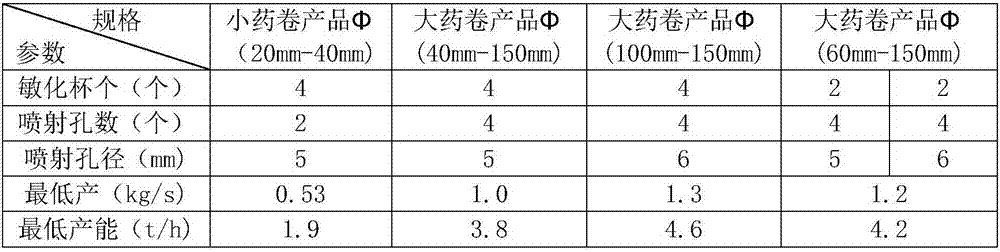

[0054] The static sensitization technology, method and device of the emulsion explosive of the present invention, through a pipe-type sensitization tube with interlayer, the front end is connected with the emulsification matrix and the sensitizer delivery pipeline, and the rear end is connected with the charging machine of a certain length. The injection pipes are connected, and the sensitization pipes are installed in a certain order in a certain order, with 2 to 6 conical sensitization cups with holes and 1 to 5 mixers. The production capacity is 2t / h to 8t / h, and the temperature is 50°C to 70°C. , Under the joint action of pressure 0.8MPa~1.5MPa and foaming agents A and B, the emulsified matrix is continuously mixed and sensitized to form a stable emulsified explosive. It is characterized in that: the emulsifying base and the sensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com