Gasifying method and device for treating low thermal value fuel

A gasification device and low calorific value technology, which is applied in waste treatment, solid waste removal, etc., can solve the problems of gasification efficiency, low calorific value of gas, small range of fuel utilization, low economic benefits, etc., and achieve environmental purification , Inhibit the formation of NOx and dioxin, and reduce the effect of air coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

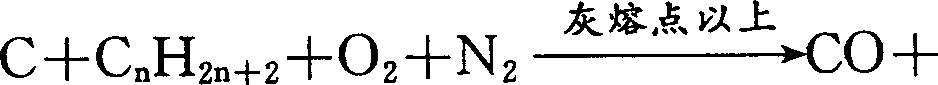

Method used

Image

Examples

Embodiment Construction

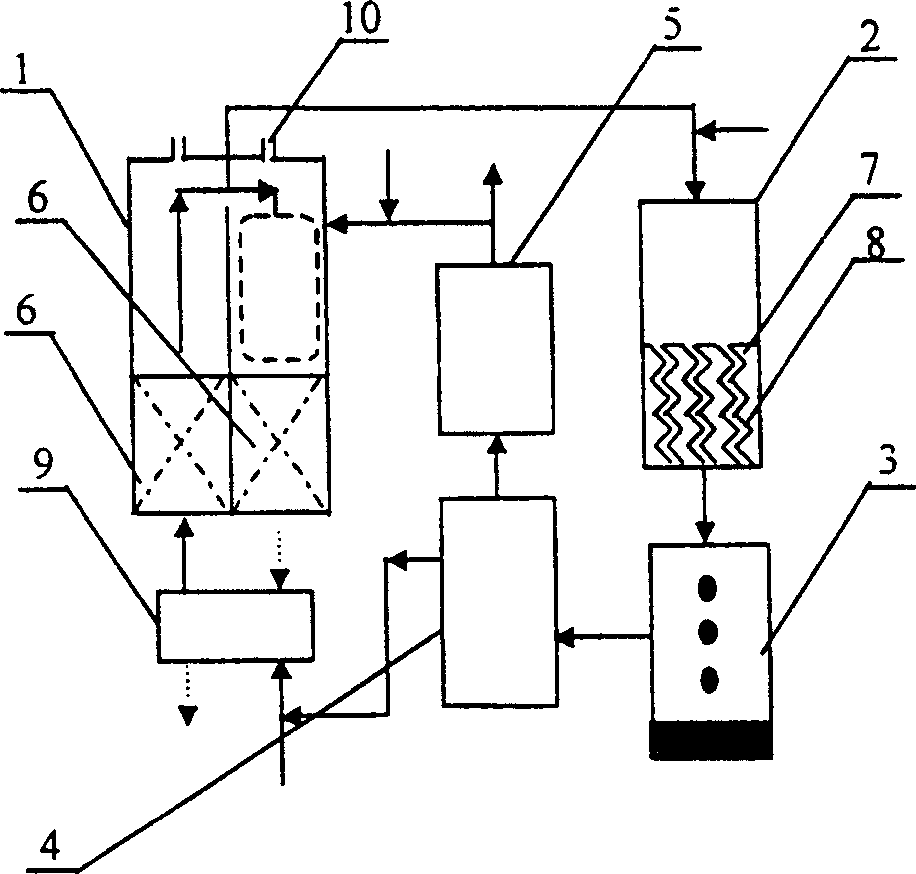

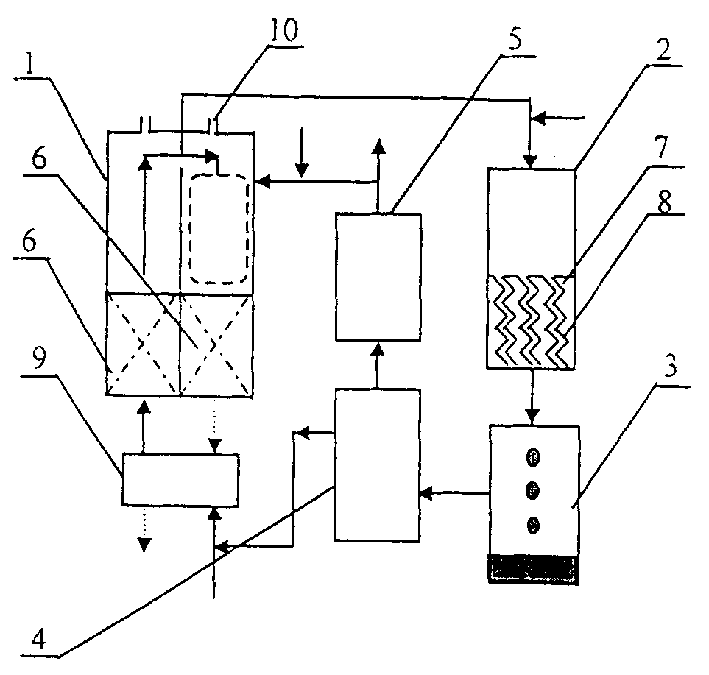

[0021] attached figure 1 It also shows the gasification working process of the present invention for processing low calorific value fuels.

[0022] The air preheater 1 is provided with two cavities on the left and right, which are respectively used as the mixed gasification agent flow channel and the combustion zone; the flue gas waste heat limit recovery devices 6 are arranged in pairs, and the passage of compressed air and low-temperature flue gas is controlled by a switching valve 9 to carry out Periodic switching, alternately passing through the flue gas waste heat limit recovery device 6; the flue gas waste heat limit recovery device 6 can preheat the normal temperature air to a level close to the airflow temperature of the combustion zone (only 100-200 °C difference); a waste heat recovery device 6 discharges When it is hot, the normal temperature air rises from room temperature to a temperature above 800°C; most of the preheated air enters the gasifier 2 from the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com