Rotary magnetic rheological liquid damper

A magneto-rheological fluid and damper technology, which is applied in the field of damping devices, can solve problems such as difficult dissipation of energy consumption and heat, increase in axial size, and complex structure, and achieve simple structure, reduced power consumption and calorific value, and compact system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

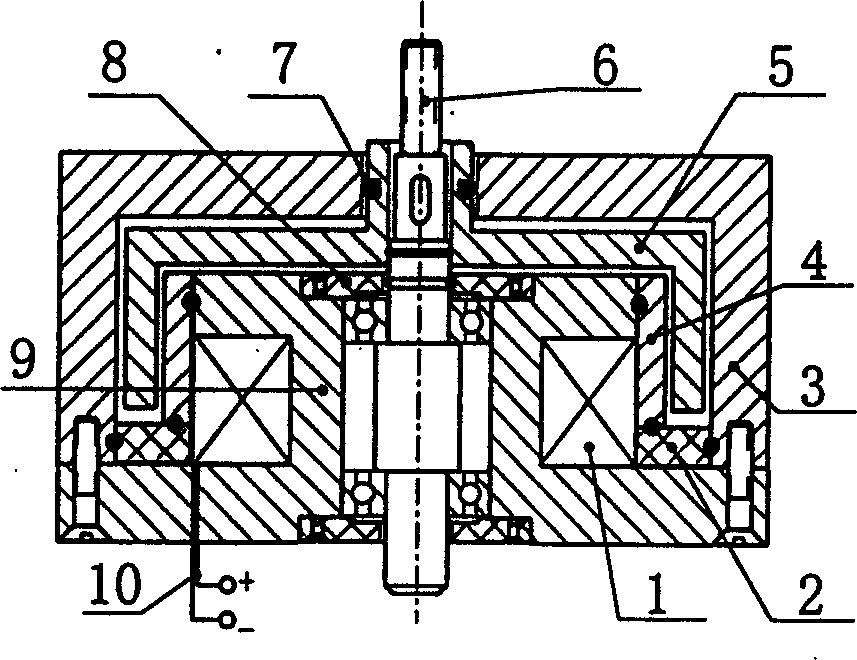

[0012] The embodiment of the present invention is as follows: the outer diameter of the damper is 116 mm, the height is 70 mm, and the diameter of the rotating shaft is 10 mm. The outer diameter of the damping barrel is 98mm, the height of the barrel is 35mm, and the wall thickness is 5mm. The electromagnetic coil is wound with 0.6mm enameled wire, the winding is 800-1000 turns, and the inner diameter is 40mm. The resistance is 6Ω. The maximum working current is 2A, and the maximum input power is 24W. Magnetorheological fluid from Lord Company of the United States is used. The damping torque provided is: 0.6Nm at zero field and 30Nm at maximum current. The magnetic field utilization rate is high, and there is almost no magnetic field leakage (under the excitation current of 2A, the magnetic field strength on the outer surface of the device is less than 0.6mT).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com