Bionic, non-smooth and abrasion-resistant roller

A non-smooth, roll technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of low production efficiency, poor wear resistance, high cost, etc., and achieve small hardness drop, good wear resistance, high The effect of cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

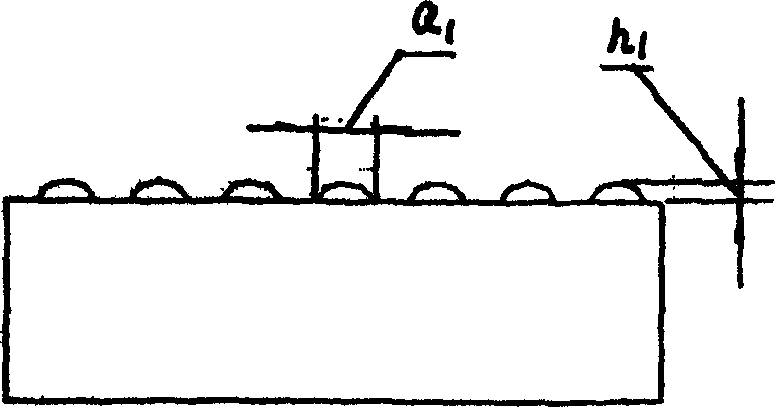

[0014] Bionic non-smooth wear-resistant roll, the core is low-carbon steel or ductile iron, the roll skin is high-carbon, high-vanadium high-speed steel composed of the above technical solutions, the surface of the roll skin is convex, refer to figure 2 , its diameter: a 1 = 50 microns, height: h 1 =25 microns, and its distribution density is 2000 pieces / 100 square millimeters.

Embodiment 2

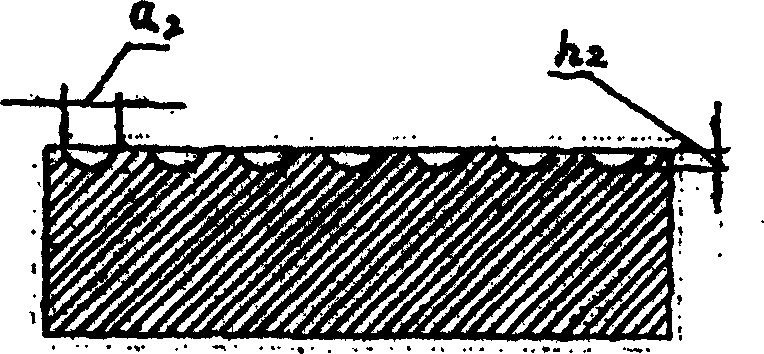

[0016] Bionic non-smooth wear-resistant roll, the core is low-carbon steel or ductile iron, the roll skin is high-carbon, high-vanadium high-speed steel composed of the above technical solutions, and the surface of the roll skin is pitted, refer to image 3 , its diameter: a 2 = 120 microns, height h 2 =50 microns, the distribution density is 1000 pieces / 100 square millimeters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com