Hand-held grinding machine

An abrasive belt grinding, hand-held technology, used in abrasive belt grinders, portable grinding machines, grinding/polishing equipment, etc., can solve the problems of shortened life of abrasive belts and drive wheels, side sliding out, and high cost. Achieve the effect of saving purchase and installation, increasing grinding allowance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

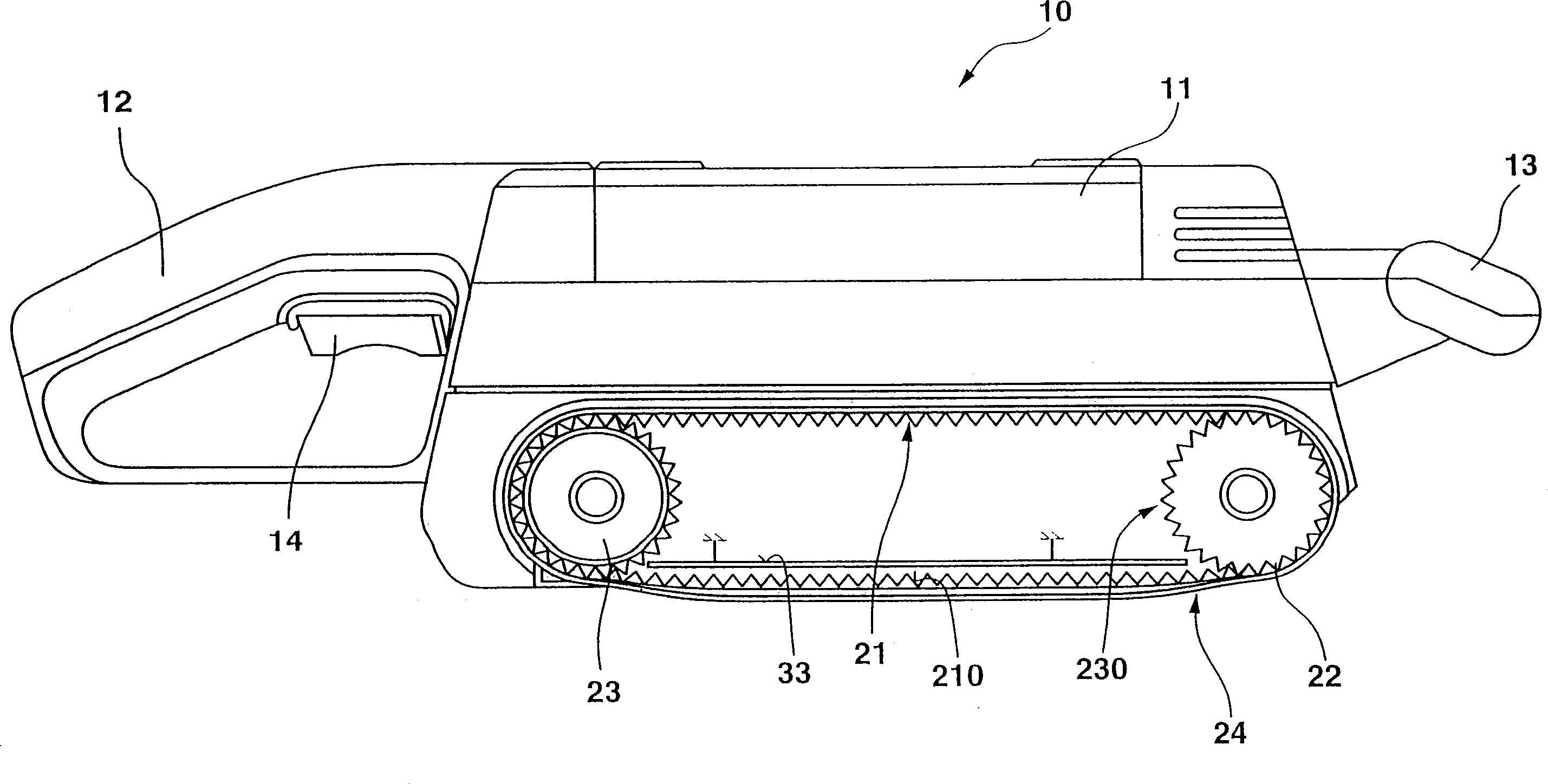

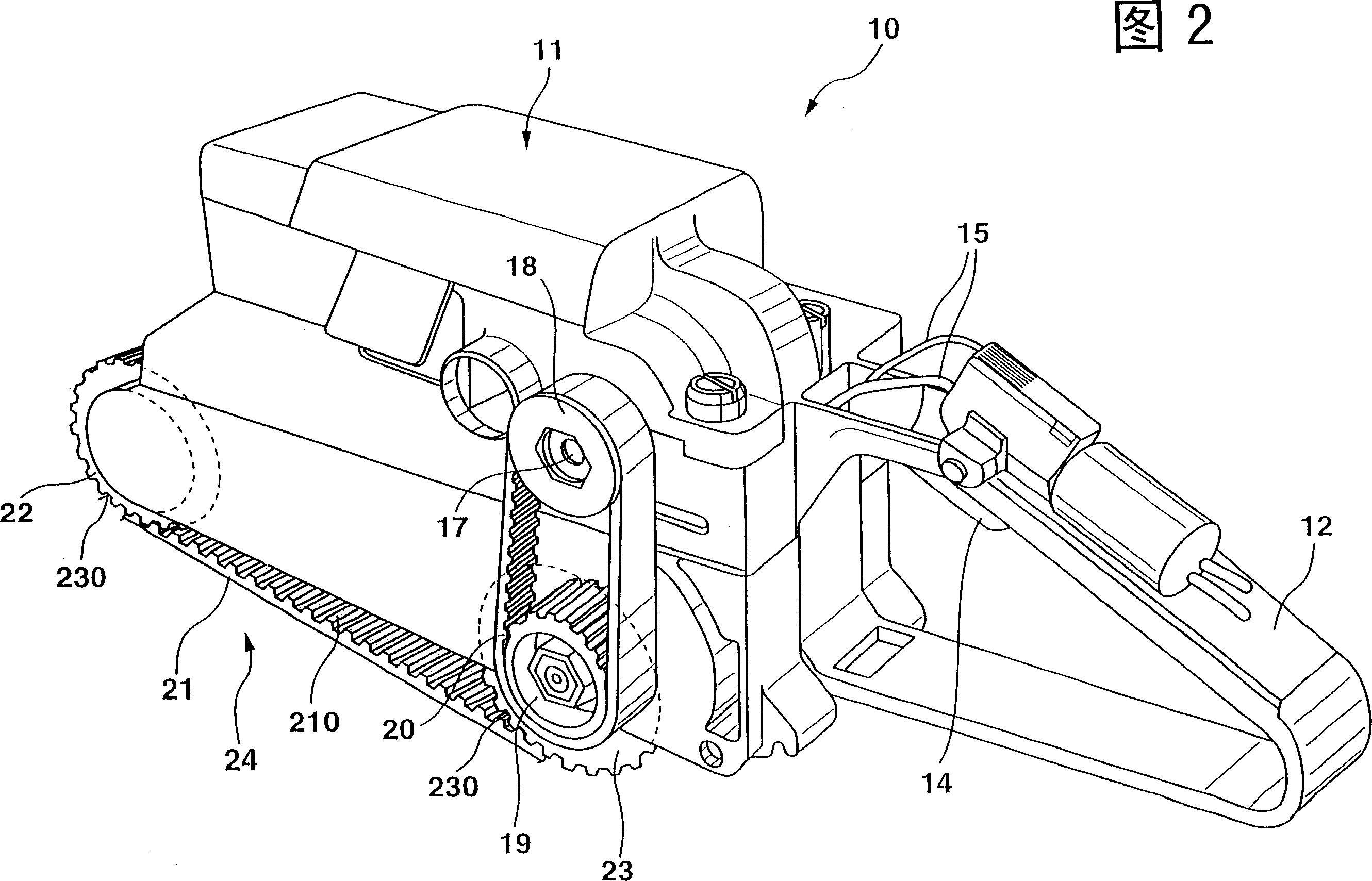

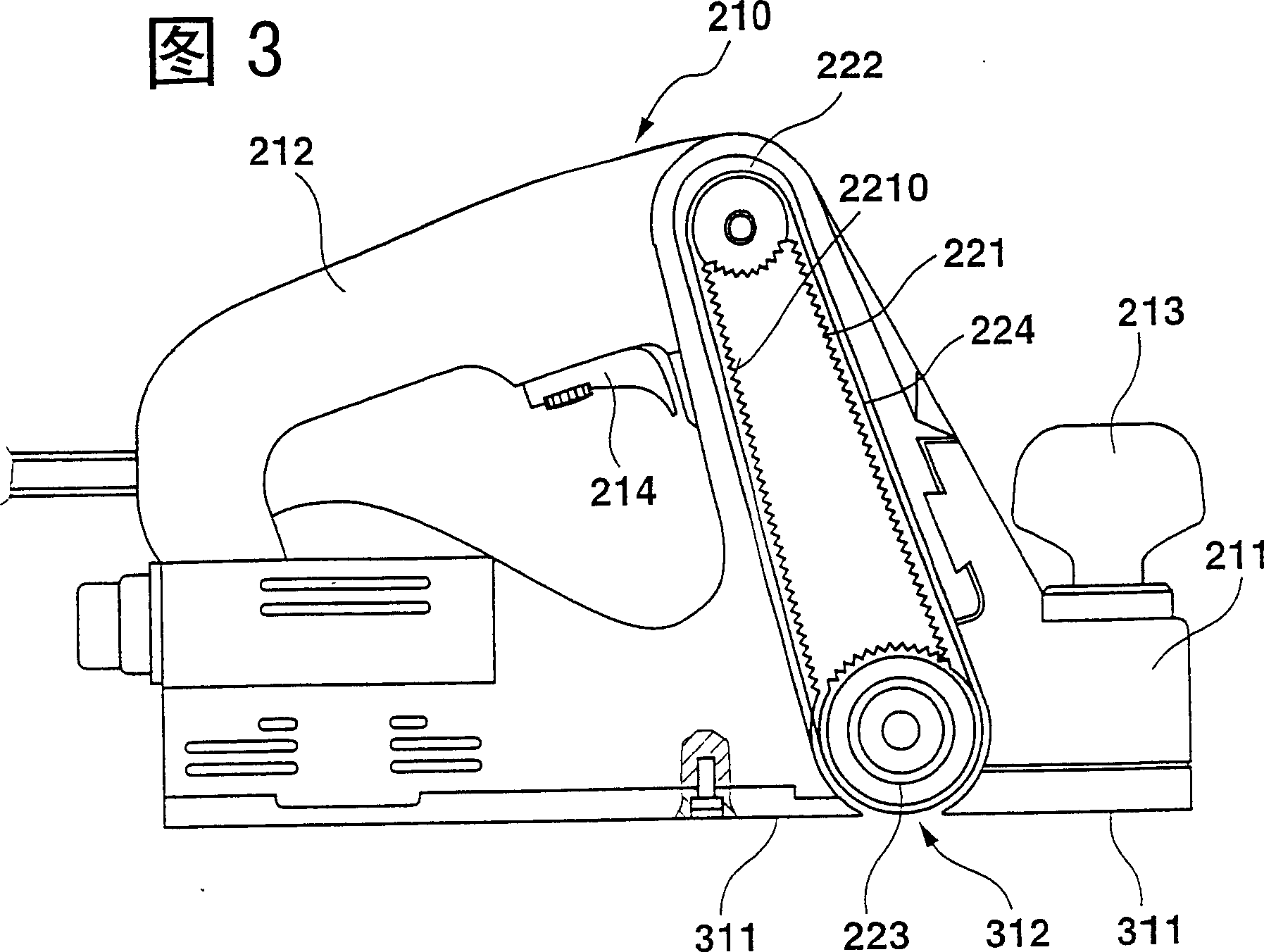

[0026] figure 1 The shown side view of a hand-held belt grinder 10 shows its housing 11 and a rear handle 12 with a switch button 14 and a front handle 13 . Furthermore, guide and drive toothed pulleys 22 , 23 arranged below the hand-held belt grinder 10 and which carry an endless toothed belt 21 in circulation can be seen.

[0027] The endless toothed belt 21 has small sticky hooks 31 on its side facing away from the teeth 21, which catch the velvet layer 32 on the back side of the abrasive belt 24, ie the opposite side of the abrasive layer 30 (FIG. 7). The hook / velvet system 31 , 32 fixes the sanding belt 24 on the endless toothed belt 21 against relative movement. The endless toothed belt forms a positive connection when its teeth 219 engage in corresponding teeth 230 of the guide and drive wheels 22 , 23 and therefore only slips to a minimum.

[0028] The abrasive belt 24 and the endless toothed belt 21 are supported with their rear sides on a shoe 33, so that the abras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com