Red fluorescent materials for electroluminescent device and its preparing process

An electroluminescence device and red fluorescence technology, which is applied in the field of optoelectronics, can solve the problems of low fluorescence efficiency and poor color purity, and achieve the effects of high fluorescence efficiency, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

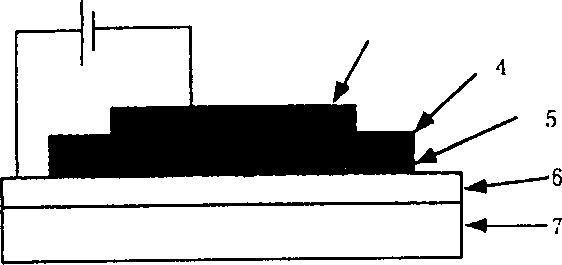

Method used

Image

Examples

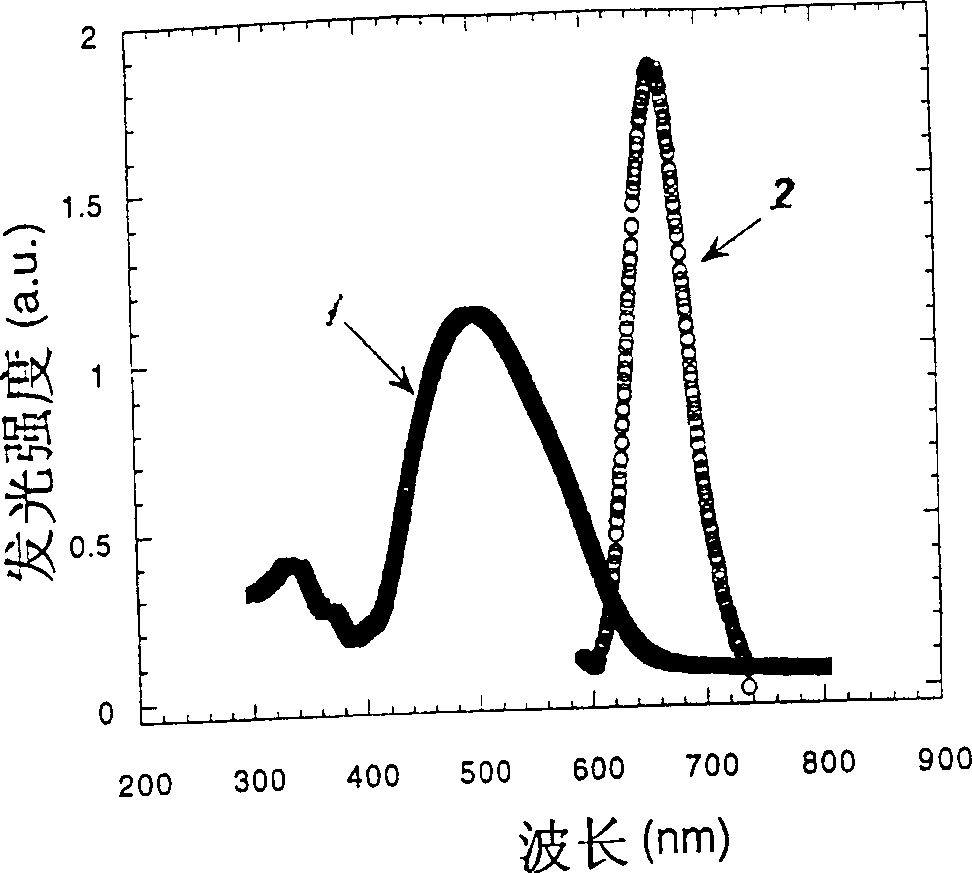

Embodiment 1

[0019] 3,5,5-trimethyl-2-cyclohexene-1 (110mmol, 15.2g) and malononitrile (100mmol, 6.6g) were dissolved in dimethylformamide (50ml) solution, and then added to the solution Add piperidine (1.5g), glacial acetic acid (0.3g) and acetic anhydride (0.2g), and stir the mixture at 80°C for 60 minutes, mix well, and then distill the mixture under reduced pressure to drive off excess dimethylformaldehyde Amide; treat the obtained product with concentrated hydrochloric acid (about 3ml) and hot water (about 100ml), and filter the obtained precipitate after treatment; add 2-propanol (15ml) and water (2ml) to the precipitate and grind thoroughly , The solid and the liquid were separated and dried to obtain a crude product. To the crude product, a mixed solution of methylene chloride and hexane with a volume ratio of 8:2 was added, and after flash chromatography, about 14 g of a red powdery solid was finally obtained. See figure 1 .

Embodiment 2

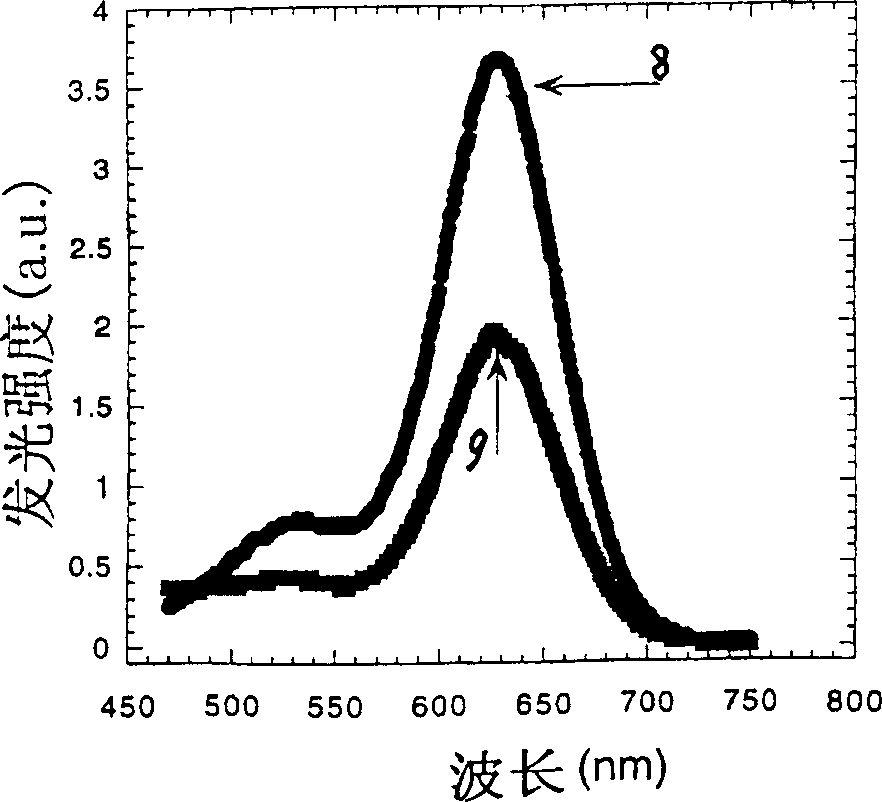

[0021] 3,5,5-Trimethyl-2-cyclohexene-1 (220mmol, 30.4g) and malononitrile (200mmol, 13.2g) were dissolved in dimethylformamide (100ml), then piperidine was added (3.0g), glacial acetic acid (0.6g) and acetic anhydride (0.4g), the mixture was stirred at 85°C for 50 minutes, then the mixture was distilled under reduced pressure to remove excess dimethylformamide, and the obtained product was concentrated Treat with hydrochloric acid (about 6ml) and hot water (about 200ml), and filter after treatment; add 2-propanol (30ml) and water (4ml) to the filtered precipitate, grind thoroughly, separate the solid and liquid, and dry; To obtain a crude product, a mixed solution of dichloromethane and hexane with a volume ratio of 8:2 was added to the crude product, and after rapid chromatographic separation, about 28 g of a red powdery solid was finally obtained. The electroluminescent spectra of the double-layer device made of the material of the present invention under different bias volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com