Tire mold laser cleaning equipment

A technology for laser cleaning and tire molds, applied to tires, household appliances, and other household appliances, can solve problems such as low work efficiency and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

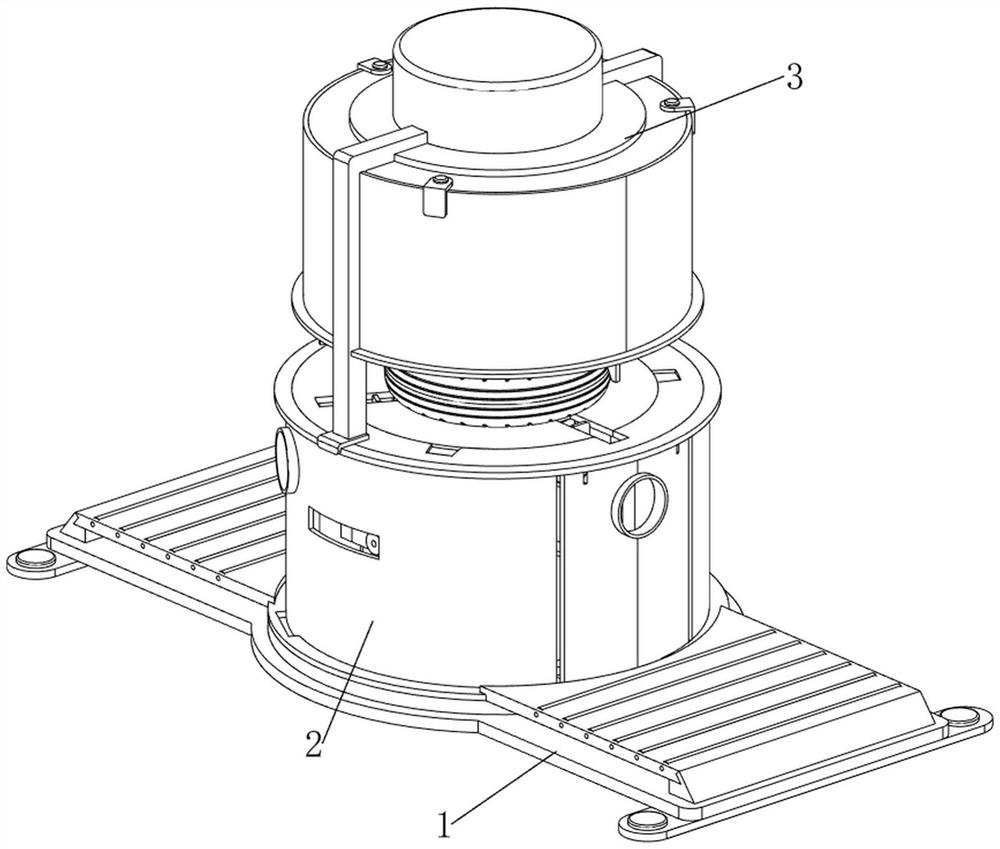

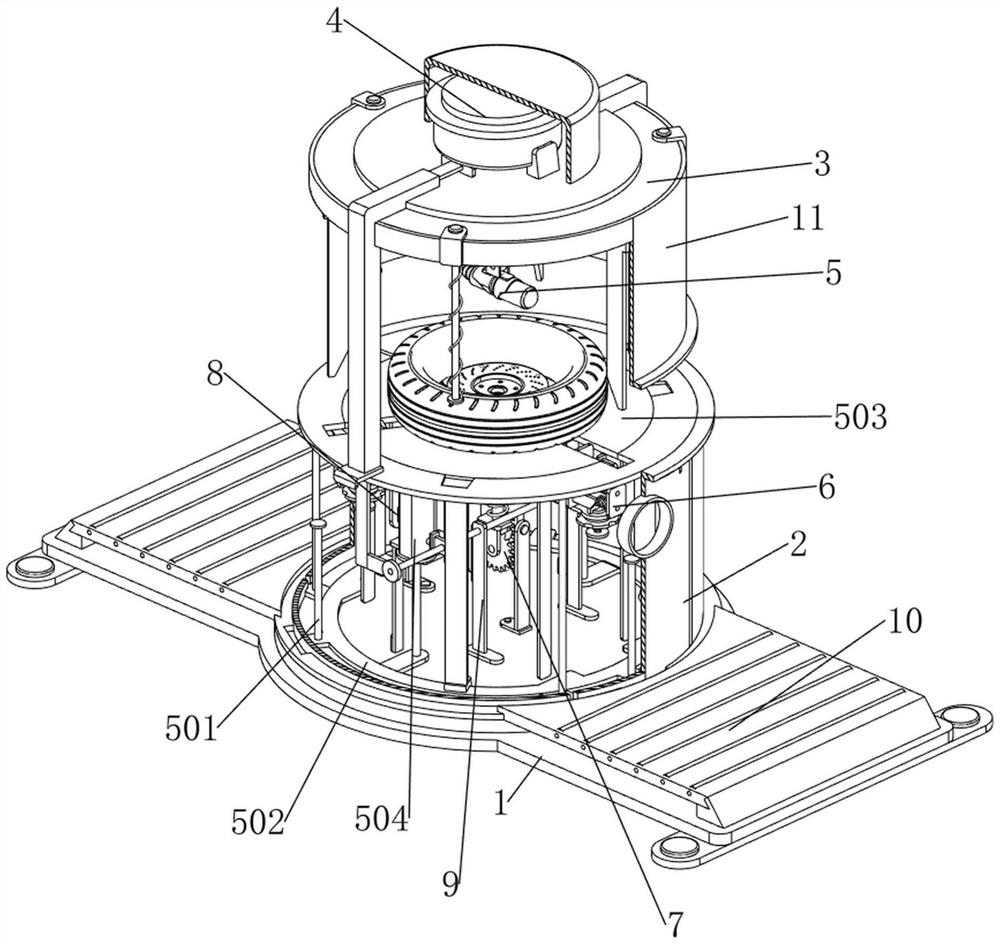

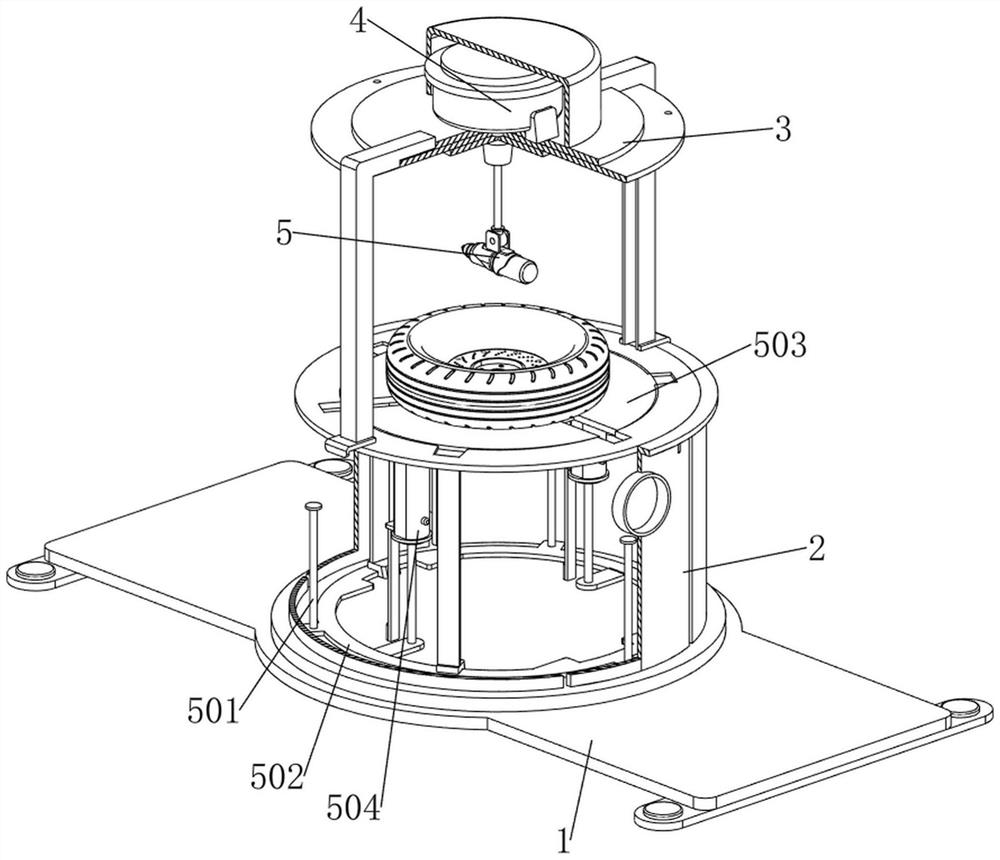

[0037] A tire mold laser cleaning equipment, such as Figure 1-3 As shown, it includes a bottom plate 1, a connecting lower frame 2, a connecting assembly 3, a motor 4, a laser 5, a first connecting rod 501, a sliding frame 502, a carrying plate 503, a cylinder 504, a centering mechanism 6 and a lifting mechanism 7, the bottom plate 1. The middle part is connected with the lower frame 2 by bolts, the top of the lower frame 2 is connected by bolts with the connection component 3, the middle of the connection component 3 is connected with the motor 4 by bolts, and the lower part of the output shaft of the motor 4 is connected with the laser instrument 5 by bolts, The laser instrument 5 can perform laser cleaning on the tire mold. The top of the bottom plate 1 is uniformly welded with first connecting rods 501 along the circumferential direction. The sliding frame 502, the sliding frame 502 can slide up and down on the first connecting rod 501, the upper part of the sliding frame...

Embodiment 2

[0042] On the basis of Example 1, as figure 2 , Figure 9 and Figure 10 As shown, it also includes a stabilization mechanism 8, which can clamp the connection plate 63, thereby improving the stability of the connection plate 63. The stabilization mechanism 8 includes an unlocking driving plate 81, a second sliding sleeve plate 82, a first clamping plate 83, an inclined surface The driving plate 84 and the third spring 85, the unlocking driving plate 81 is connected to the top left side of the bottom plate 1 by bolts, the second sliding sleeve plate 82 is connected to the bottom left side of the bearing plate 503 by bolts, and the second sliding sleeve plate 82 is slidably connected There is a first card plate 83, the first card plate 83 can slide on the second sliding sleeve plate 82, when the connecting plate 63 moves upward and contacts the first card plate 83, it will push the first card plate 83 to the left, and the first card plate 83 is pushed to the left. The left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com