Technological method for fixing safety belt for working on machine body

A process method and technology of seat belts, applied in the direction of seat belts, life-saving equipment, etc., can solve problems such as hidden safety hazards, and achieve the effects of improving work efficiency, increasing adaptability, and increasing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

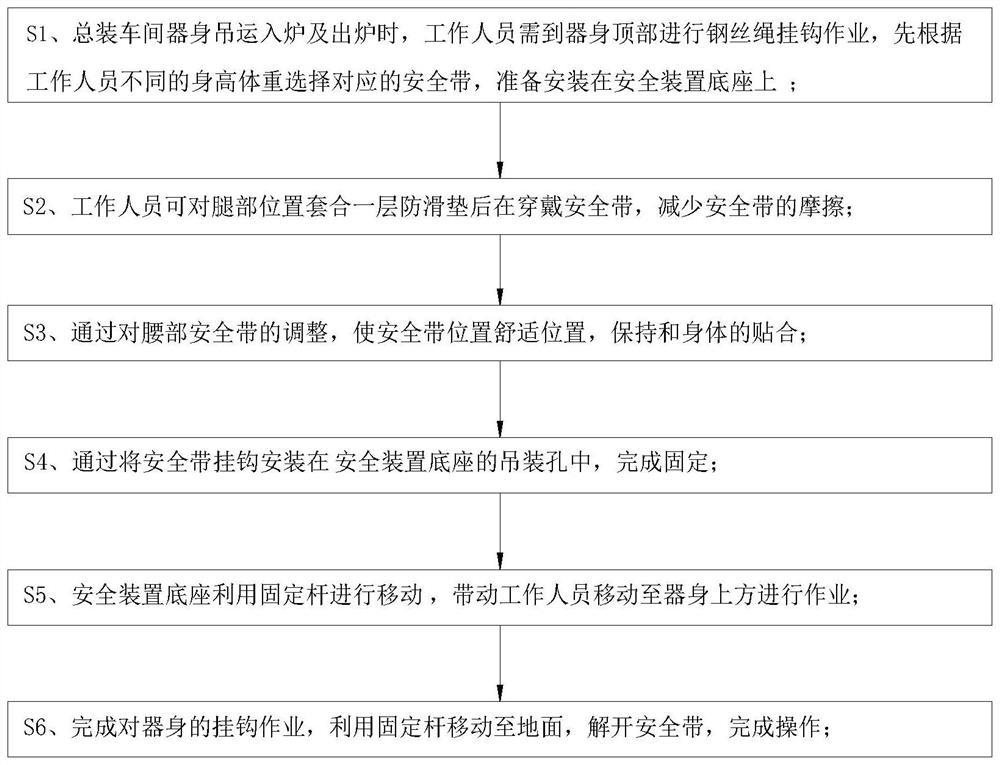

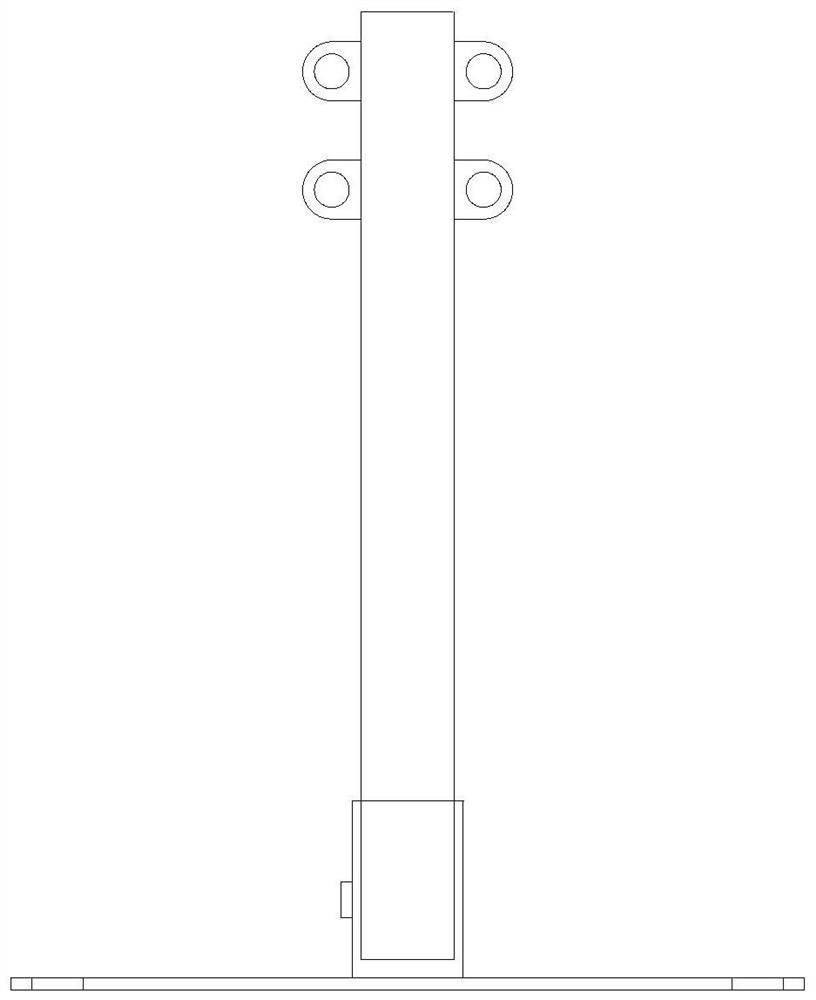

[0028] see Figure 1-2 As shown in the figure, a method for fixing a seat belt on a body, the following steps:

[0029] S1: When the body of the assembly workshop is hoisted into and out of the furnace, the staff needs to go to the top of the body to carry out the wire rope hooking operation. First, select the corresponding seat belt according to the different height and weight of the staff, and prepare to install it on the base of the safety device; use safety The belt protects the installation work of the staff. At the same time, the safety belts of different specifications can also adapt to the employees of different heights and sizes, increasing the adaptability of the safety belts in work.

[0030] S2: The staff can put a layer of anti-friction pads on the legs and then wear the seat belts to reduce the friction of the seat belts; the use of anti-friction pads can reduce the friction between the seat belts and the skin of the staff, and reduce the scratches caused to the ...

Embodiment 2

[0043] A process method for fixing a safety belt on the body of the device. Comparative Example 1, as another embodiment of the present invention, the base of the safety device in S1 adopts a steel plate welded steel pipe structure, and the surface is treated with colorless spray plastic, and sprayed at the same time. Fluorescent material; the use of fluorescent material can remind the staff of the position of the base of the safety device when the staff walks at night, reducing the risk of tripping or bumping.

[0044]Working principle: When the body of the assembly workshop is hoisted into and out of the furnace, the staff needs to go to the top of the body to carry out the wire rope hooking operation. First, select the corresponding seat belt according to the different height and weight of the staff, and prepare to install it on the base of the safety device. Then the staff can put a layer of anti-friction pads on the legs and wear the seat belts to reduce the friction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com