Starch-based nanoparticles of double-embedded beta-carotene as well as preparation method and application of starch-based nanoparticles

A carotene and nanoparticle technology, applied in the field of emulsification, can solve problems such as protein instability, easy aggregation, and unsatisfactory emulsification performance of a single protein, and achieve the effects of wide sources, simple preparation process, and high stability against environmental stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Specifically, as an aspect of the technical solution of the present invention, a method for preparing starch-based nanoparticles with double-embedded β-carotene involved includes:

[0024] The starch is subjected to enzymatic hydrolysis treatment, precipitation and classification treatment to obtain dextrin;

[0025] Dextrin is acylated with butyric anhydride to obtain butyrylated dextrin;

[0026] By adopting a co-precipitation method, the butyrylated dextrin and β-carotene are embedded to obtain a butyrylated dextrin / β-carotene inclusion complex;

[0027] Ultrasonic modification of gliadin is carried out to obtain ultrasonically modified gliadin;

[0028] The pH value of the alkaline mixed system comprising the butyrylated dextrin / β-carotene inclusion complex, ultrasonically modified gliadin and β-carotene is adjusted to 7.5 and self-assembly occurs to prepare a double The starch-based nanoparticles embedded with beta-carotene, wherein the pH value of the alkaline m...

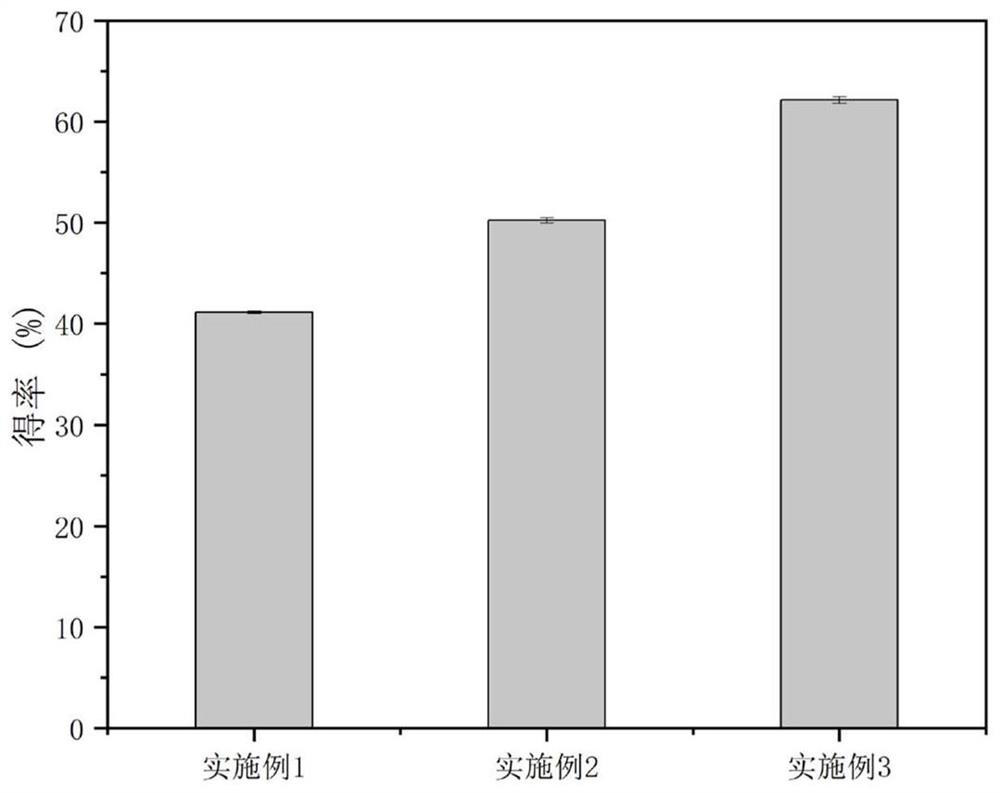

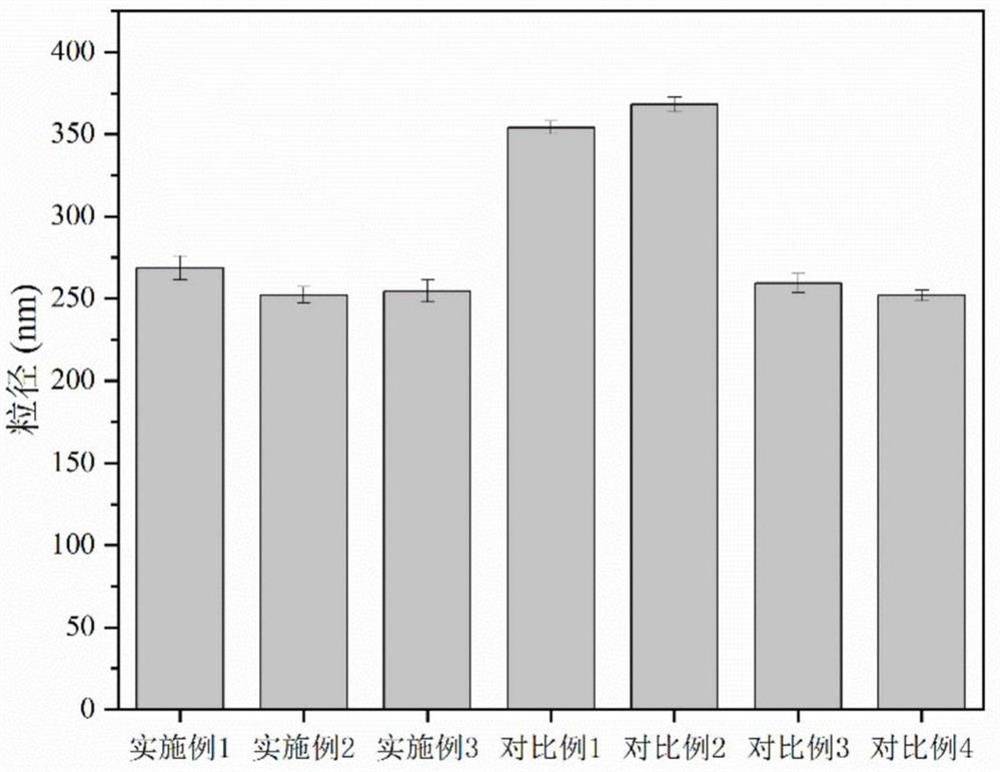

Embodiment 1

[0069] (1) Preparation of corn dextrin

[0070] Using 0.01 mol / L disodium hydrogen phosphate-sodium dihydrogen phosphate buffer with pH 5, corn starch was prepared into a starch suspension with a mass fraction of 5%, and then placed in a boiling water bath and stirred for 1 h until the starch was completely gelatinized. After the gelatinized starch is cooled to 45°C, pullulanase is added for hydrolysis reaction, the time is 22h, the pH value of the hydrolysis reaction system is 5, and the addition amount of pullulanase is 100U / g (calculated on the dry basis of starch); After the hydrolysis treatment was completed, the product was centrifuged (4500 g, 20 min), and the supernatant was rotary-evaporated at 55° C. and lyophilized to obtain crude dextrin.

[0071] The crude dextrin suspension with a concentration of 5% was prepared using an ethanol solution with a volume ratio of ethanol and deionized water of 1:1, stirred in a water bath at 60 °C for 4 h, and then centrifuged at 4...

Embodiment 2

[0084] (1) Preparation of corn dextrin

[0085] Using 0.01 mol / L disodium hydrogen phosphate-sodium dihydrogen phosphate buffer with pH 5.5, corn starch was prepared into a starch suspension with a mass fraction of 5%, and then placed in a boiling water bath and stirred for 1 h until the starch was completely gelatinized. After the gelatinized starch is cooled to 50°C, pullulanase is added for hydrolysis reaction, the time is 23h, the pH value of the hydrolysis reaction system is 5.5, and the addition amount of pullulanase is 125U / g (calculated on the dry basis of starch); After the hydrolysis treatment was completed, the product was centrifuged (4500 g, 20 min), and the supernatant was rotary-evaporated at 55° C. and lyophilized to obtain crude dextrin.

[0086] The crude dextrin suspension with a concentration of 5% was prepared by using an ethanol solution with a volume ratio of ethanol and deionized water of 1:1, stirred in a water bath at 60 °C for 4 h, and then centrifuged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com