Device and method for testing fluidity of candy processed product

A technology for processing products and testing devices, which is applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of testing equipment without temperature control, easy sticking of sugar products, and difficult cleaning, etc., to achieve a wide range of testing, Easy to operate, avoid the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

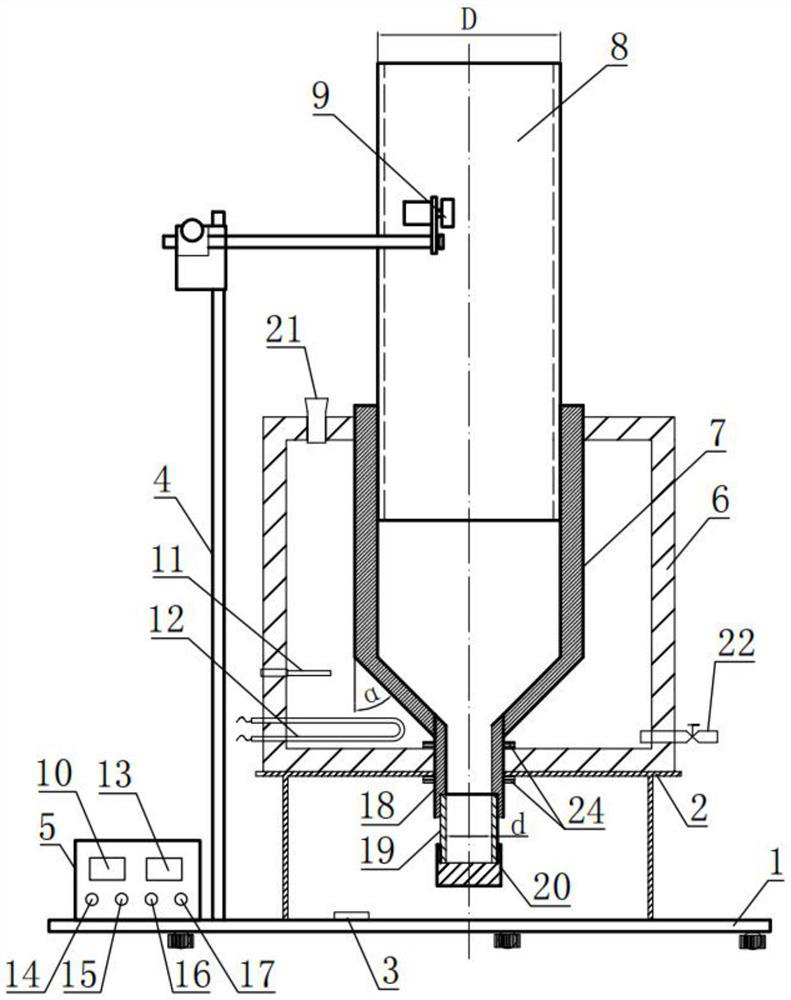

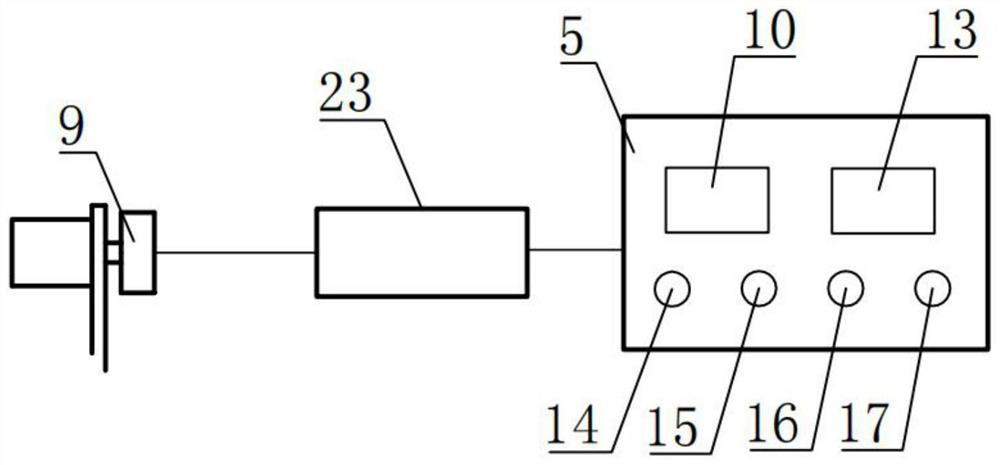

[0053] Embodiment 1: The method for testing the fluidity of sugar material after the low-intensity aerated candy simmering process utilizes the above-mentioned fluidity testing device for processed candy products, comprising the following steps:

[0054] S1: Test preparation: adjust the test table to be in a horizontal state according to the spirit level 3, check the constant temperature heating box 6, put the plunger 8 into the plunger sleeve 7, turn on the power switch 15 on the electrical control box 5, and manually rotate the encoder 9 The stroke sensor of the encoder, the encoder stroke measuring instrument 10 is in a normal working state, press the measurement reset button 17 to reset;

[0055] S2: Select the discharge pipe 19 with an inner hole diameter of 20.00mm;

[0056] S3: Set the measured temperature value on the temperature controller 13 to 122°C, turn on the heating switch 14, and after the measured temperature reaches 122°C, keep it for more than 60 minutes, so...

Embodiment 2

[0064] Embodiment 2: The method for testing the fluidity of sugar material after the gel candy simmering process utilizes the above-mentioned fluidity testing device for processed confectionery products, comprising the following steps:

[0065] S1: Test preparation: adjust the test table to be in a horizontal state according to the spirit level 3, check the constant temperature heating box 6, put the plunger 8 into the plunger sleeve 7, turn on the power switch 15 on the electrical control box 5, and manually rotate the encoder 9 The stroke sensor of the encoder, the encoder stroke measuring instrument 10 is in a normal working state, press the measurement reset button 17 to reset;

[0066] S2: Select the discharge pipe 19 with an inner hole diameter of 13.33mm;

[0067] S3: Set the measured temperature value on the temperature controller 13 to 108°C, and turn on the heating switch 14. After the measured temperature reaches 108°C, keep it for more than 60 minutes, so that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com