Direct-current variable-frequency air conditioner compressor capable of automatically releasing pressure and using method

An air-conditioning compressor, DC frequency conversion technology, which is applied in the direction of machines/engines, liquid variable-capacity machinery, mechanical equipment, etc. In order to achieve the effect of thermal insulation transmission, improve production efficiency, and prevent heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

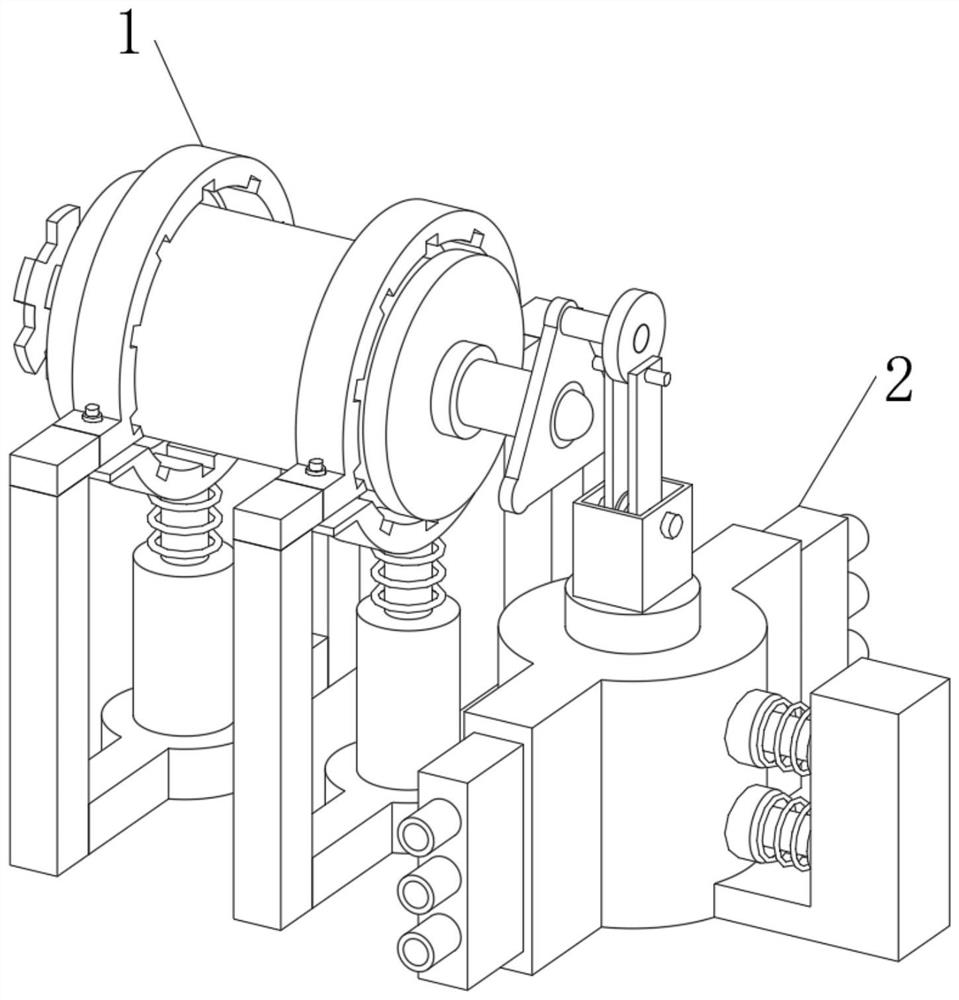

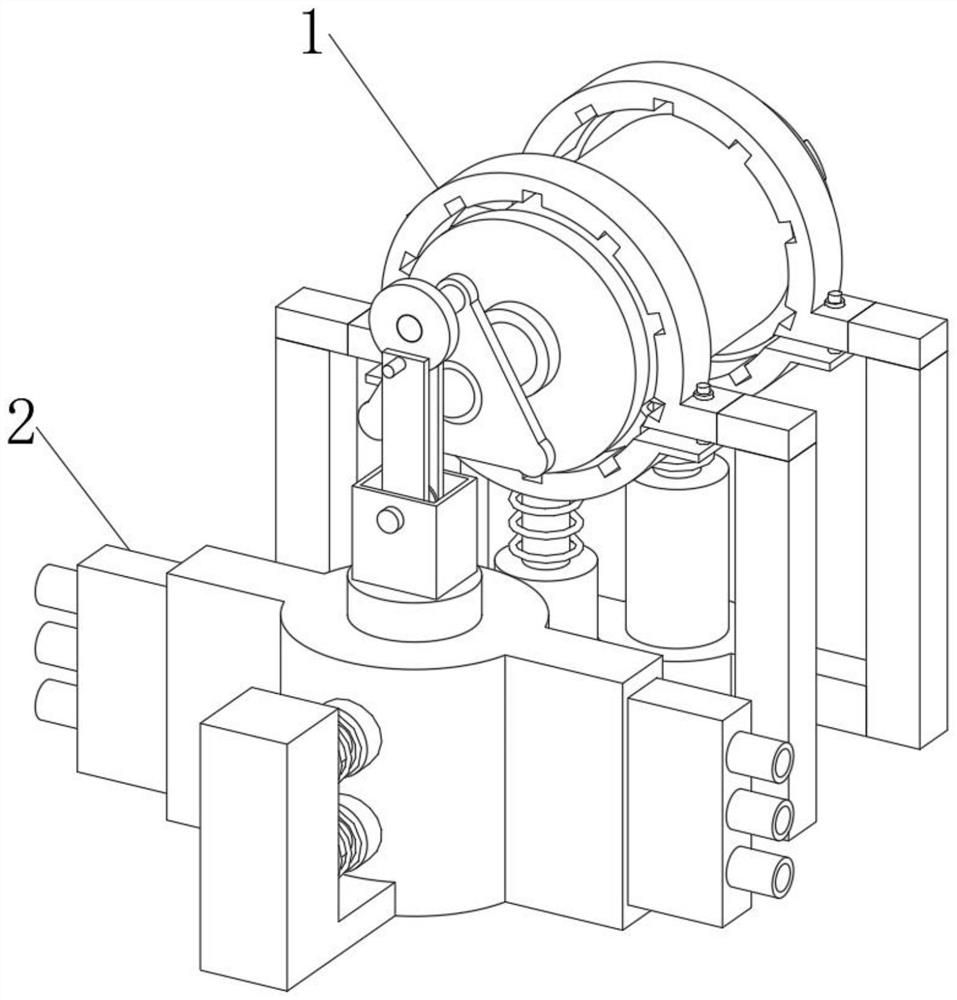

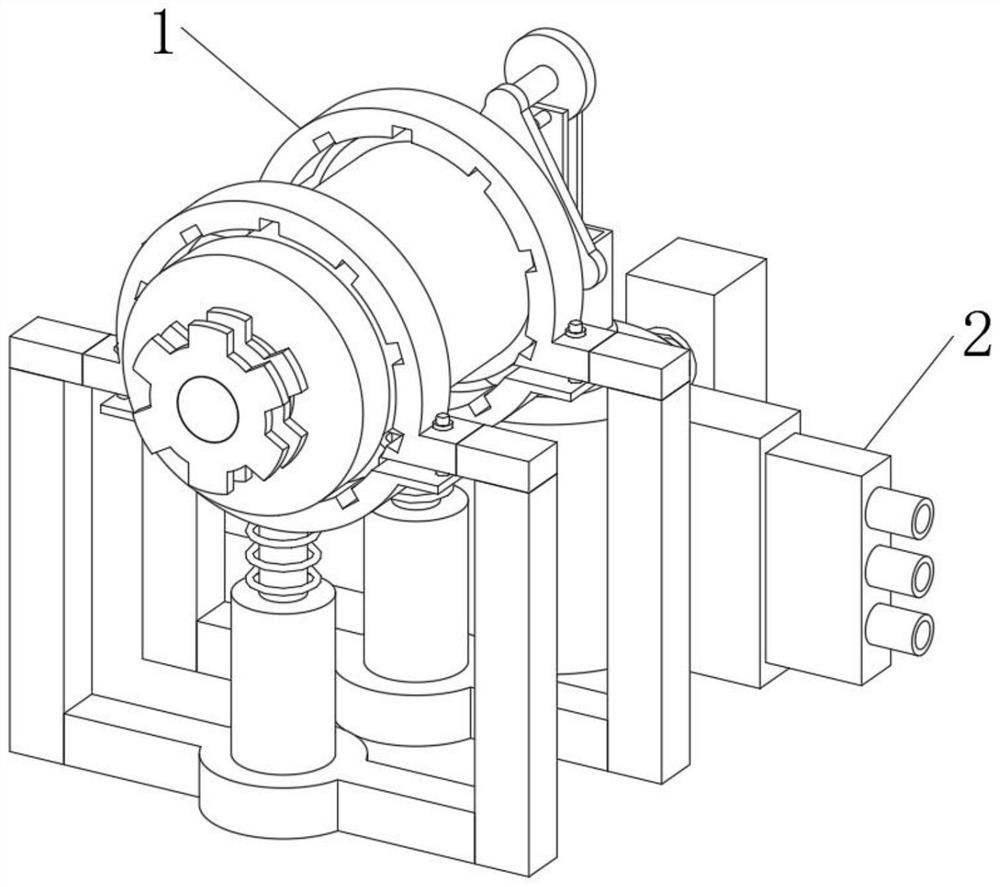

[0040] see figure 1 , figure 2 , image 3 , an embodiment provided by the present invention: a DC variable frequency air conditioner compressor that can automatically relieve pressure, including a drive conduction structure 1 and a compression extrusion structure 2, the side end position of the drive conduction structure 1 and the compression extrusion structure 2 The phase-rotating connection is arranged, and the connection and installation work is facilitated by the setting of the driving conduction structure 1 and the compression extrusion structure 2;

[0041] see Figure 4 , the drive transmission structure 1 includes a protective sleeve frame 3, a drive connection member 4, a spring seat 5, a guide rod frame 6, a rotating hinge frame 7, a transmission link 8, a rotating hinge plate 9 and a hinged column frame 10, and the drive connection member 4 is provided with At the center of the inner end of the drive conduction structure 1, the center of the drive connection pa...

Embodiment 2

[0048] On the basis of Example 1, as Figure 8 As shown, the side end of the compression extrusion structure 2 is wrapped and connected with a second protective thermal insulation layer 25, the center of the second protective thermal insulation layer 25 is provided with a first protective thermal insulation layer 24, a first protective thermal insulation layer 24, a second protective thermal insulation layer 25 A third protective and thermal insulation layer 26 is fixedly connected to the top of 25 .

[0049] In the implementation of this embodiment, the user installs the first protective insulation layer 24, the second protective insulation layer 25 and the third protective insulation layer 26 to achieve the purpose of heat preservation, prevent the heat loss of the compressed gas, and realize the internal heat preservation function , and the first protection and insulation layer 24, the second protection and insulation layer 25, the third protection and insulation layer 26 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com