Catalyst for producing hydrogen through large-current electro-catalysis water decomposition as well as preparation method and application of catalyst

An electrocatalytic, high-current technology, applied in electrolysis components, electrolysis process, electrodes, etc., can solve the problems of low current density of hydrogen evolution reaction, limited application prospects, single catalytic site, etc., to achieve process controllable, excellent electrochemistry Performance and stability of catalytic water splitting for hydrogen production, and the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Mix 15 mL of concentrated hydrochloric acid with a mass fraction of 36.0% and 30 mL of anhydrous ethanol, and stir evenly, then immerse a piece of 2cm×4cm×1.5mm foam nickel current collector in it, and ultrasonically treat it for 30min to remove the metal oxides and organic substances on the surface. . The nickel foam was taken out, washed three times with deionized water, and placed in 45 mL of deionized water for 30 min to sonicate to remove residual hydrochloric acid and ethanol, and set aside.

[0095] Dissolve 0.6 mmol of ammonium molybdate tetrahydrate and 2.4 mmol of cobalt nitrate hexahydrate in 60 mL of deionized water, and stir well to dissolve. The mixed solution was transferred to a 100 mL reaction kettle, the pretreated nickel foam was added, and the reaction was heated to 150 °C for 6 h. After the reaction, it was naturally cooled to room temperature, and the bulk material was taken out and washed three times with deionized water, and dried in an oven at ...

Embodiment 2

[0100] Using the metal precursor bulk material prepared in Example 1, it was placed in a vacuum tube furnace under 300mL / min H 2 Under the reducing atmosphere of / Ar mixed gas (hydrogen-argon volume ratio 1 / 9), the catalyst was heated to 400°C at a heating rate of 5°C / min, kept for 2 h, and then cooled to room temperature naturally. The obtained catalyst was recorded as CoO / CoMoO 4 . After calculation, based on the total weight of the catalyst, the total loading of active components in the catalyst prepared in this implementation is 66.10 wt %.

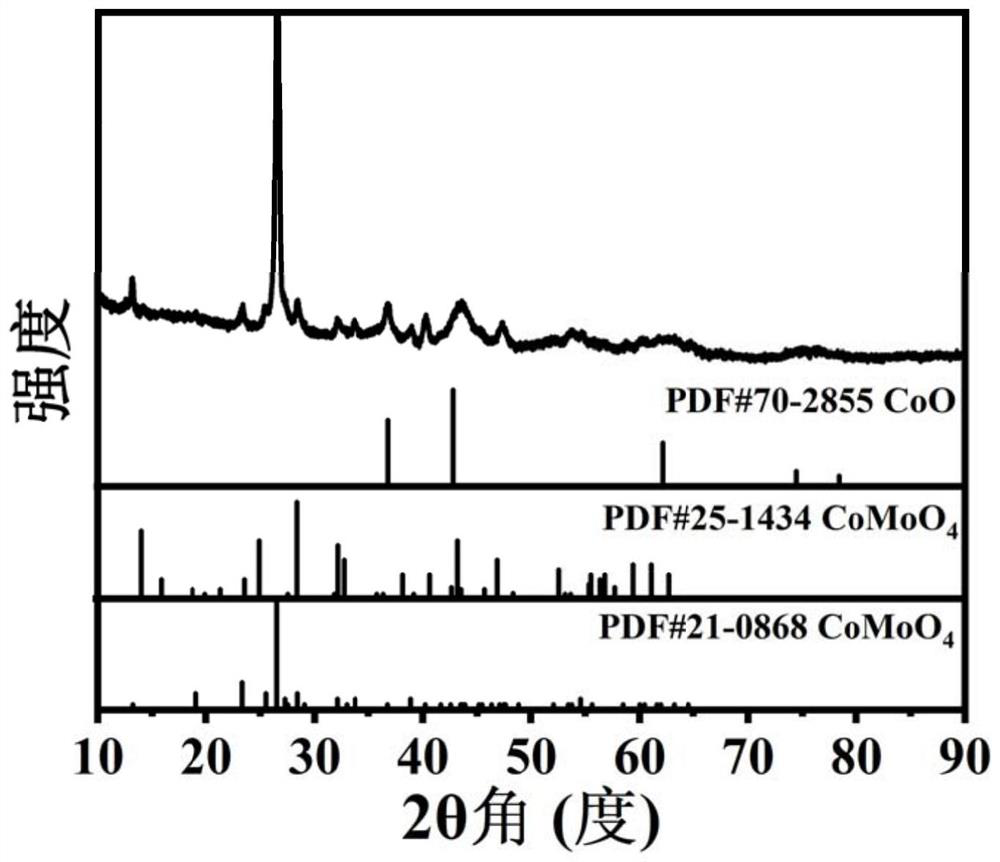

[0101] image 3 The XRD pattern of the catalyst prepared in this example is shown. It can be seen that the catalyst prepared in this example is composed of CoO and CoMoO 4 composition of two phases.

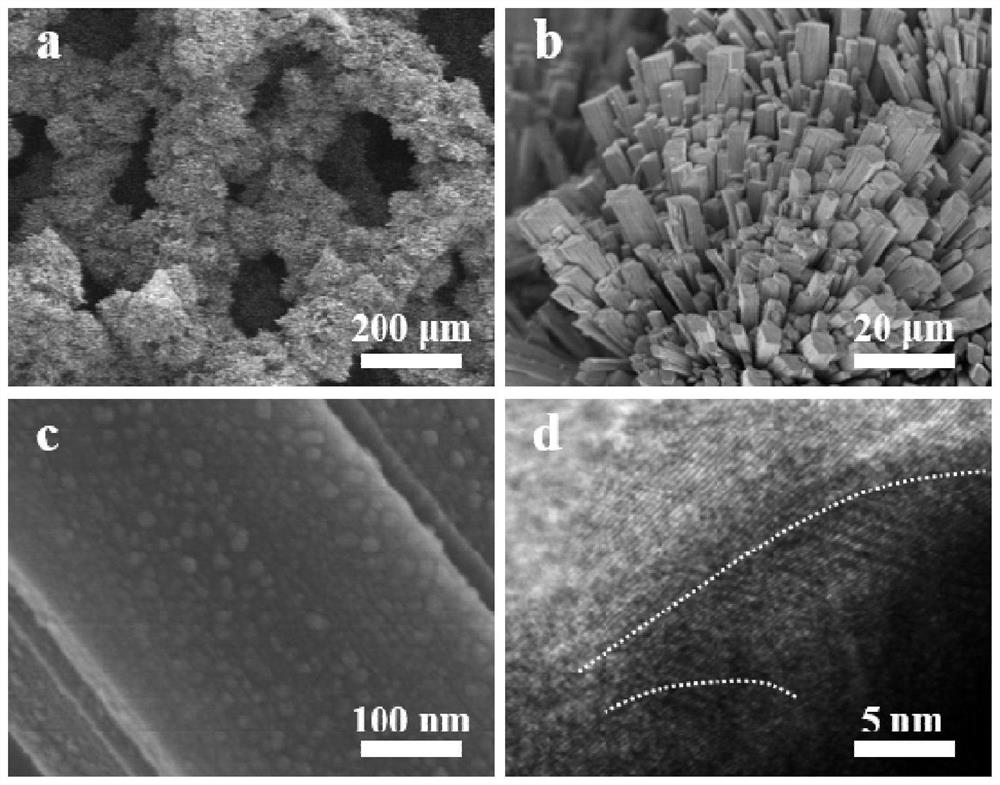

[0102] Figure 4 SEM images (a-c) and HRTEM images (d) of the catalyst prepared in this example. It can be seen that CoO / CoMoO 4 The main structure is also composed of rod-like CoMoO 4 The composition of CoO particles on its surf...

Embodiment 3

[0104] The metal precursor bulk material prepared in Example 1 was placed in a vacuum tube furnace, and was heated at 300 mL / min of H 2 / Ar mixed gas (hydrogen-argon volume ratio 1 / 9) in a reducing atmosphere, heated to 600 °C at a heating rate of 5 °C / min, kept for 2 h, and then cooled to room temperature naturally, the obtained catalyst was recorded as CoMo / CoO / CoMoO 3 . After calculation, based on the total weight of the catalyst, the total loading of the active components in the catalyst prepared in this implementation is 59.20 wt %.

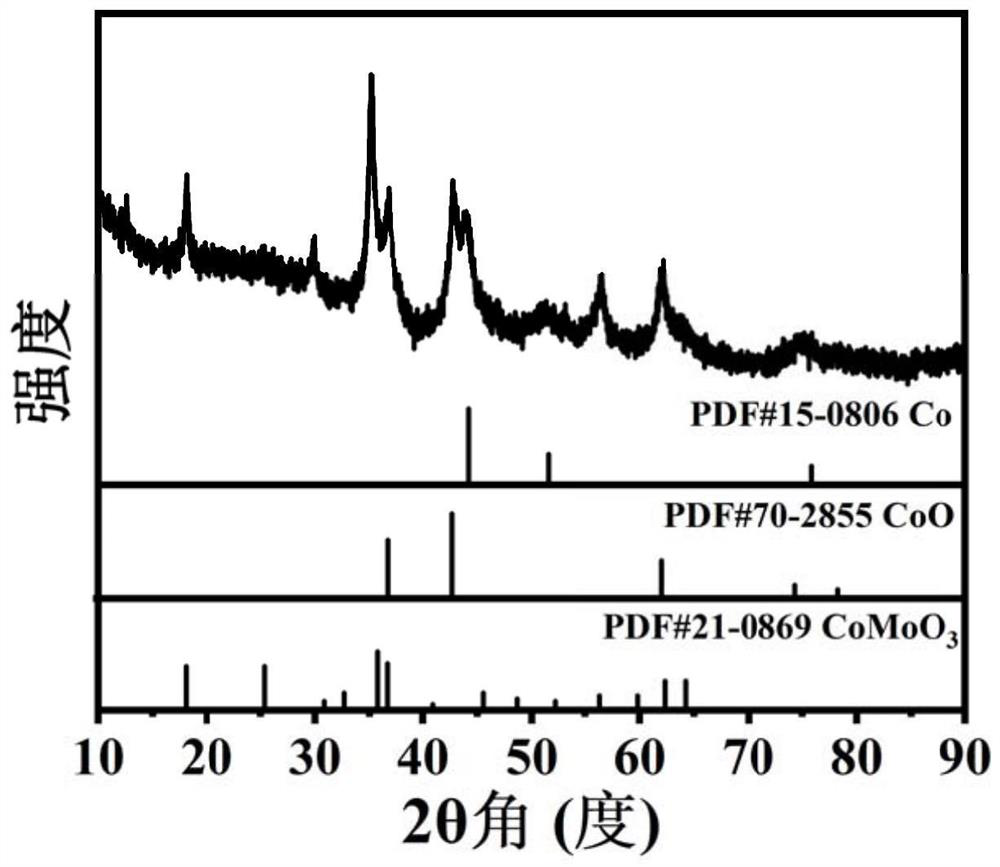

[0105] Figure 5 The XRD pattern of the catalyst prepared in this example is shown. It can be seen that the catalyst prepared in this example is composed of CoMo, CoO and CoMoO 3 composed of three phases.

[0106] Image 6 SEM images (a-c) and HRTEM images (d-f) of the catalyst prepared in this example. It can be seen that CoMo / CoO / CoMoO 3 It consists of a rod-like structure and its surface particles, but the particle size increases s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com