Polypeptide synthesizer for preparing thymalfasin raw material

A new technology of peptide synthesis and thymus method, which is applied to the preparation method of peptides, peptides, hormone peptides, etc., can solve the problems of low convenience, low use efficiency, and high cost of use, so as to increase the convenience of use, avoid the connection process, The effect of increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

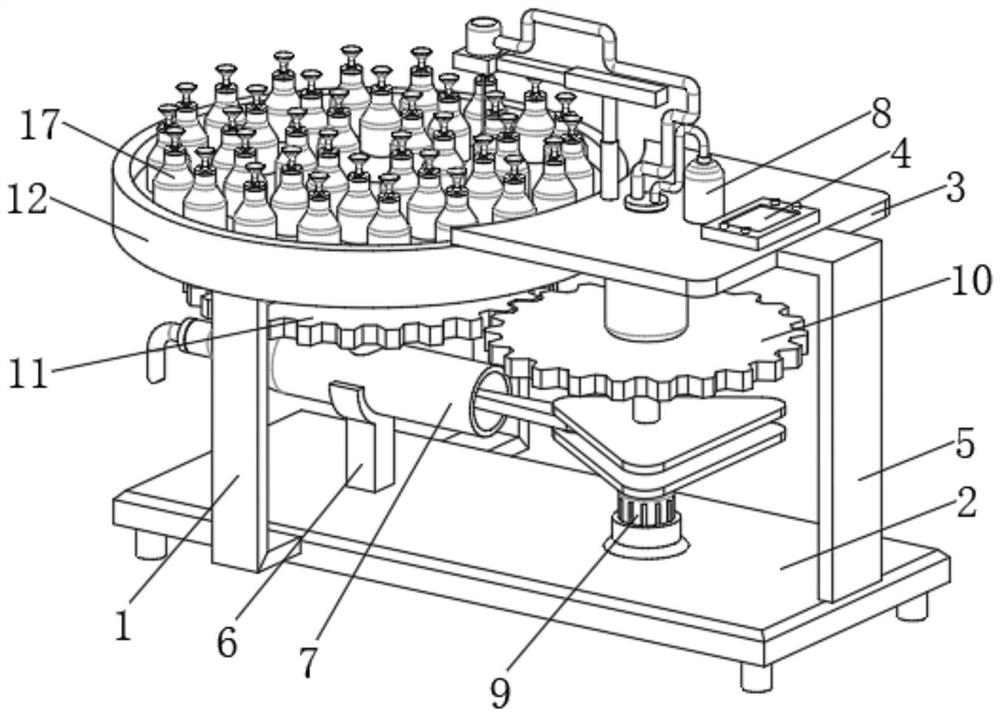

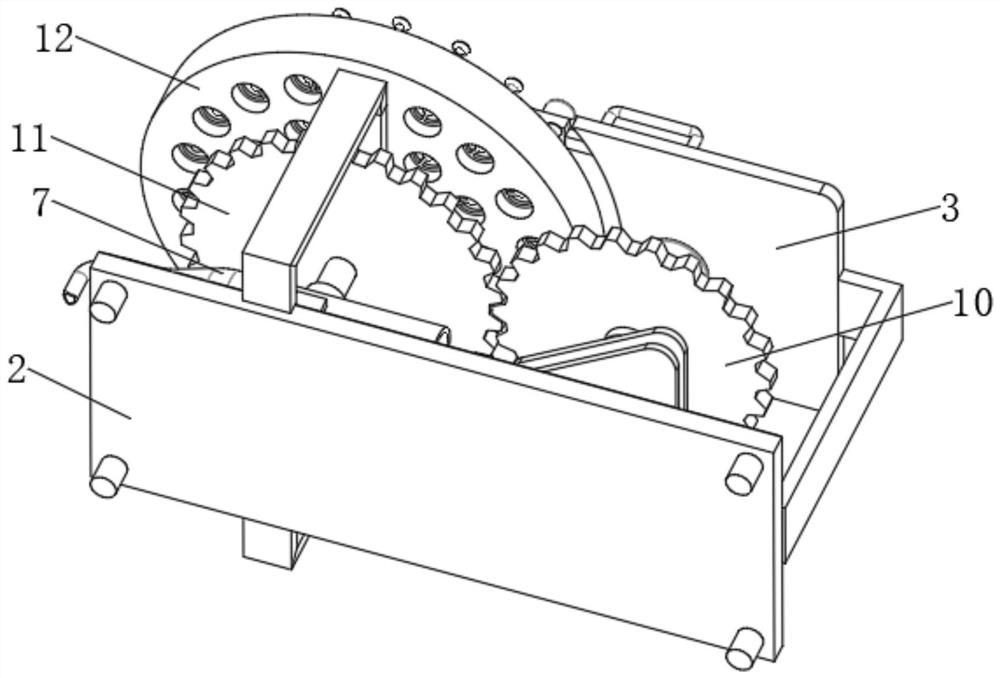

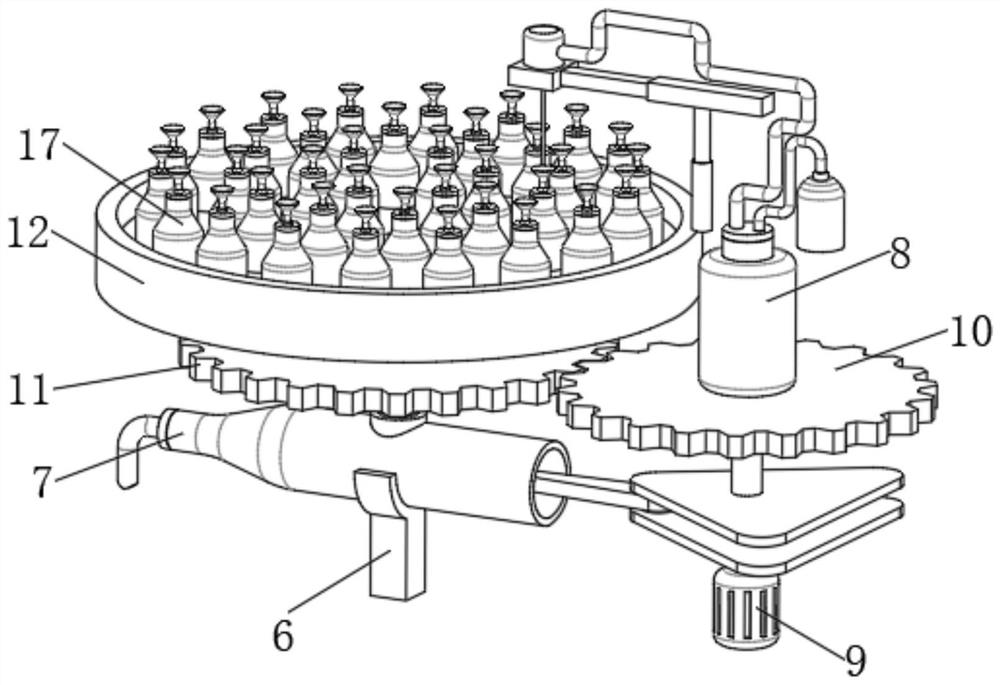

[0043] In the process of absorbing amino acids, the servo motor 9 can be activated to drive the upper driving gear 10 to rotate through one end of the waste discharge assembly 7, and the rotation of the driving gear 10 can be used to drive the relative rotation of the driven gear 11, and The rotation of the storage tray 12 can be driven by the driven gear 11 . At this time, the rotation angle of the storage tray 12 can be precisely controlled under the control of the servo driver, so that the amino acid storage device 17 to be added is located in the positive direction of the injection assembly 8 Below, the second telescopic rod 802 is activated at the same time to drive the relative displacement of the movable block 803 and the displacement of the suction pipe 804 below, so that the suction pipe 804 is located directly below the amino acid storage device 17 to be added. At this time, by controlling the first telescopic rod 801 The suction pipe 804 can be inserted into the inte...

no. 2 example

[0049] The waste liquid generated in the preparation process will enter the interior of the feed port 702 through the waste discharge pipe 15, and enter the waste discharge tank 701 to complete the temporary storage, and when the servo motor 9 is started, it will drive the upper drive shaft 708 without The regular rotation can drive the relative rotation of the movable block 707 at this time, and the relative rotation of the movable block 707 can drive the connecting rod 706 at the front end to swing. 705 can only move left and right relative to the waste discharge tank 701, which causes the other end of the connecting rod 706 to swing and drive the piston 705 to move left and right, and the piston 705 has an irregular left and right displacement. At this time, the waste liquid inside the waste discharge tank 701 is The pressure from the piston 705 can be applied to the one-way flap valve 703 to open the one-way flap valve 703 and discharge through the output pipe 704 to comple...

no. 3 example

[0054] In the process of absorbing amino acids, since the driving gear 10 can be rotated under the drive of the servo motor 9, the bottom end of the reaction tank 807 is connected with the bottom end of the driving gear 10. When the servo motor 9 drives the driving gear 10 When the random rotation of the reversing is performed, the reaction tank 807 located at the top of the driving gear 10 at this time performs reversing and irregular rotation, and at this time, various amino acids located in the reaction tank 807 can be under the action of the rotation of the reaction tank 807. After thorough mixing, the reaction is completed and the polypeptide is synthesized.

[0055] By using the random rotational motion of the servo motor 9 under its servo program, the reversing and variable-speed rotational motion of the reaction tank 807 can be realized. The use of uniform mixing in the device leads to the phenomenon of low mixing efficiency, and because the power source during mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com