Method for continuously modifying soybean protein isolate based on modified atmosphere assisted low-temperature plasma

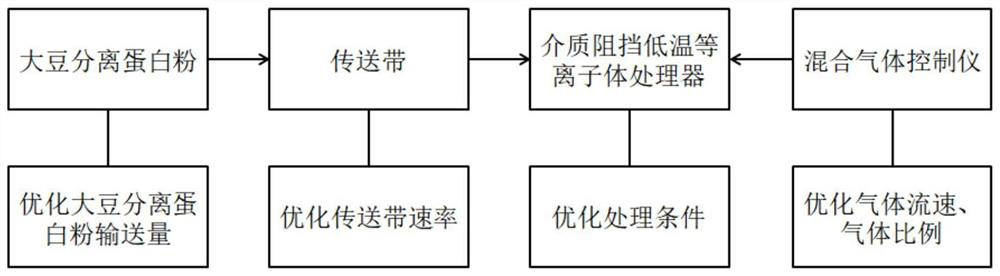

A low-temperature plasma and soybean protein isolate technology, which is applied in the field of soybean protein isolate modification, can solve the problems of undiscovered soybean protein isolate, cumbersome treatment process, and long processing time, so as to reduce the protein modification process and improve the modification effect , Reduce the effect of modification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

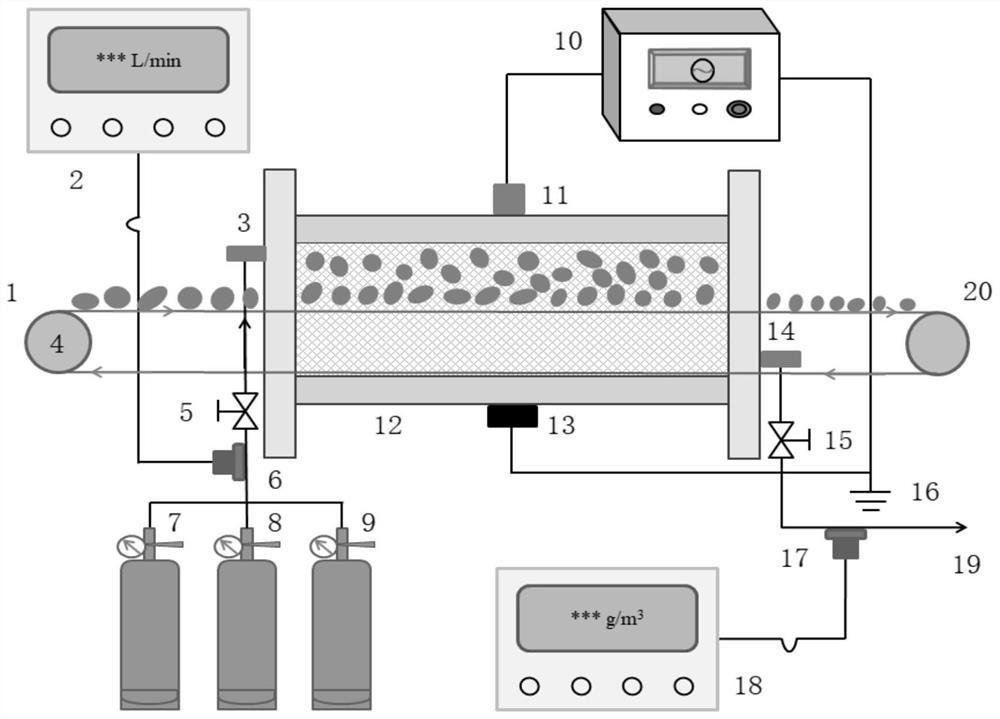

[0028] The method for continuous modification of soybean protein isolate based on modified atmosphere assisted low-temperature plasma in this embodiment is as follows:

[0029]The soybean protein isolate powder is fed into the dielectric barrier discharge low-temperature plasma generator at a load of 100g / min through a conveyor belt of 20cm / min, and then a certain proportion of nitrogen and oxygen are charged into the generator at a flow rate of 8L / min. Mixed gas with carbon dioxide (volume ratio is 30% O 2 +50%N 2 +20%CO 2 ); low-temperature plasma treats the mixed gas and soybean protein isolate in the generator, the treatment time is 120s, the treatment voltage is 40kV, and the treatment frequency is 75Hz; after the treatment, the gas in the plasma generator is discharged for analysis and treatment , the modified soybean protein isolate powder is sent out and packaged to obtain a modified commercial soybean protein isolate. It has been determined that the soy protein iso...

Embodiment 2

[0031] The soybean protein isolate powder is fed into the dielectric barrier discharge low-temperature plasma generator at a load of 80g / min through a conveyor belt of 40cm / min, and then a certain proportion of nitrogen and oxygen are charged into the generator at a flow rate of 20L / min. Mixed gas with carbon dioxide (volume ratio is 40% O 2 +40%N 2 +20%CO 2 ); low-temperature plasma processes the mixed gas and soybean protein isolate in the generator, the processing time is 180s, the processing voltage is 70kV, and the processing frequency is 90Hz; after the processing, the gas in the plasma generator is discharged for analysis and processing , the modified soybean protein isolate powder is sent out and packaged to obtain a modified commercial soybean protein isolate. It has been determined that the soy protein isolate powder of this embodiment has improved solubility, gelation, emulsifying and emulsifying stability, foaming and foaming stability by 12.6%, 7.7%, and 51.8%, ...

Embodiment 3

[0033] The soybean protein isolate powder was fed into the dielectric barrier discharge low-temperature plasma generator at a load of 30g / min through a conveyor belt of 50cm / min, and then a certain proportion of nitrogen and oxygen were charged into the generator at a flow rate of 15L / min. Mixed gas with carbon dioxide (50% O by volume 2 +30%N 2 +20%CO 2 ); low-temperature plasma processes the mixed gas and soybean protein isolate in the generator, the processing time is 300s, the processing voltage is 110kV, and the processing frequency is 135Hz; after the processing, the gas in the plasma generator is discharged for analysis and processing , the modified soybean protein isolate powder is sent out and packaged to obtain a modified commercial soybean protein isolate. It was determined that the solubility, gelatinity, emulsifying property, emulsifying stability, foaming property and foaming stability of the soybean protein isolate powder of this example were improved by 19.0%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com