Super-retarding durable concrete and preparation process thereof

A durable concrete and ultra-retarded technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems affecting the early strength and compressive strength of concrete, and affect the quality of finished concrete products, so as to promote Heat transfer, good retarding effect, and effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

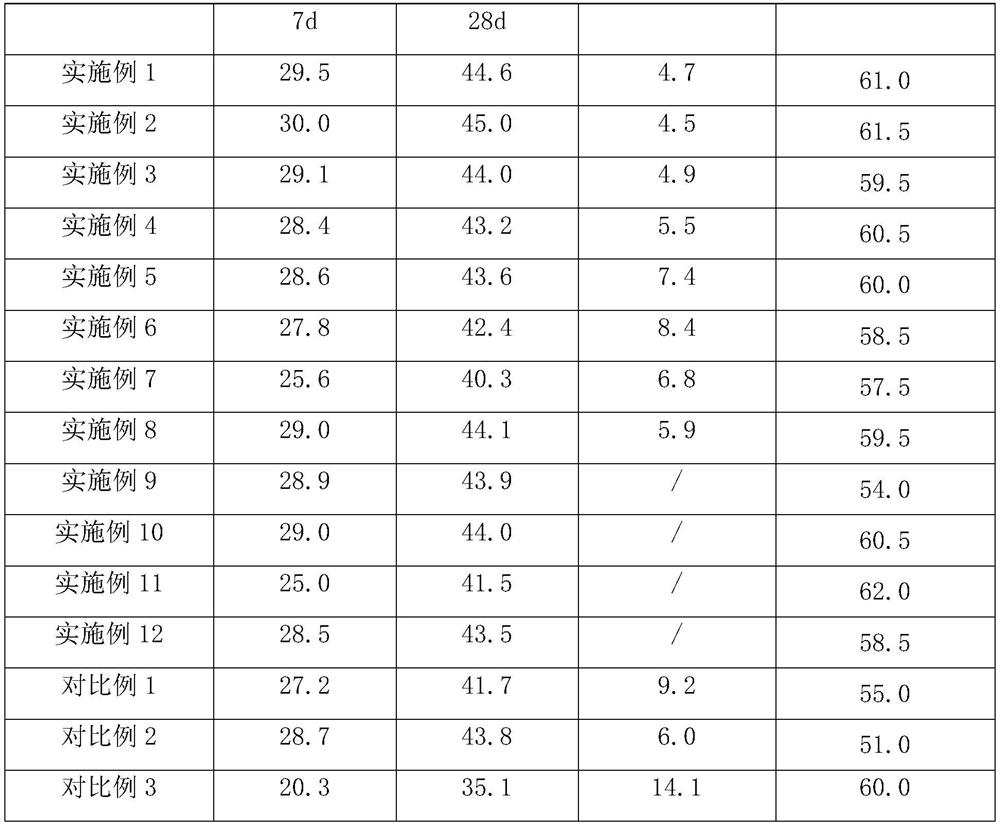

Examples

preparation example 1

[0042] Preparation Example 1: The composite fiber was prepared by the following method:

[0043] Weigh 0.4kg of sodium alginate solution and spray evenly on the surface of 1kg polypropylene fiber, the length of polypropylene fiber is 3mm, and the sodium alginate solution is an aqueous solution of sodium alginate with a mass fraction of 1%, then add 0.75kg of carbon fiber, the length of carbon fiber is 3mm, and stir well. Then, add 0.35kg of polyethylene glycol 8000, continue to stir evenly, the particle size of polyethylene glycol 8000 is 20 mesh, and after drying, it is dispersed into polypropylene fibers without large-area agglomeration, and the finished composite fiber is obtained, and the size of the composite fiber is less than 8mm.

preparation example 2

[0044] Preparation Example 2: The composite fiber was prepared by the following method:

[0045] Weigh 0.2kg of sodium alginate solution and spray evenly on the surface of 1kg polypropylene fiber, the length of polypropylene fiber is 3mm, and the sodium alginate solution is a sodium alginate aqueous solution with a mass fraction of 0.5%, then add 0.4kg of carbon fiber, the length of carbon fiber is 3mm, stir well Then, add 0.2kg of polyethylene glycol 8000, continue to stir evenly, the particle size of polyethylene glycol 8000 is 20 mesh, and after drying, it is dispersed into polypropylene fibers without large-area agglomeration, and the finished composite fiber is obtained, and the size of the composite fiber is less than 8mm.

preparation example 3

[0046] Preparation Example 3: The composite fiber was prepared by the following method:

[0047] Weigh 0.6kg of sodium alginate solution and spray evenly on the surface of 1kg polypropylene fiber, the length of polypropylene fiber is 3mm, the sodium alginate solution is a sodium alginate aqueous solution with a mass fraction of 2%, and then 1kg of carbon fiber is added, and the length of carbon fiber is 3mm. , add 0.5kg of polyethylene glycol 8000, continue to stir evenly, the particle size of polyethylene glycol 8000 is 20 mesh, and after drying, it is dispersed into polypropylene fibers without large-scale agglomeration, and the finished composite fiber is obtained, and the size of the composite fiber is less than 8mm .

[0048] Preparation example of hydroxycarboxylic acid modified filler

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com