Large-size two-dimensional amorphous metal oxide material and preparation method thereof

A technology of amorphous metals and oxides, applied in the direction of chromium oxide/hydrate, chemical instruments and methods, zirconia, etc., can solve problems such as difficulty in forming sheet-shaped amorphous metal oxides, complexity, etc., and achieve rapid reaction process Efficient, huge application space, pollution-free and macro-quantified preparation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

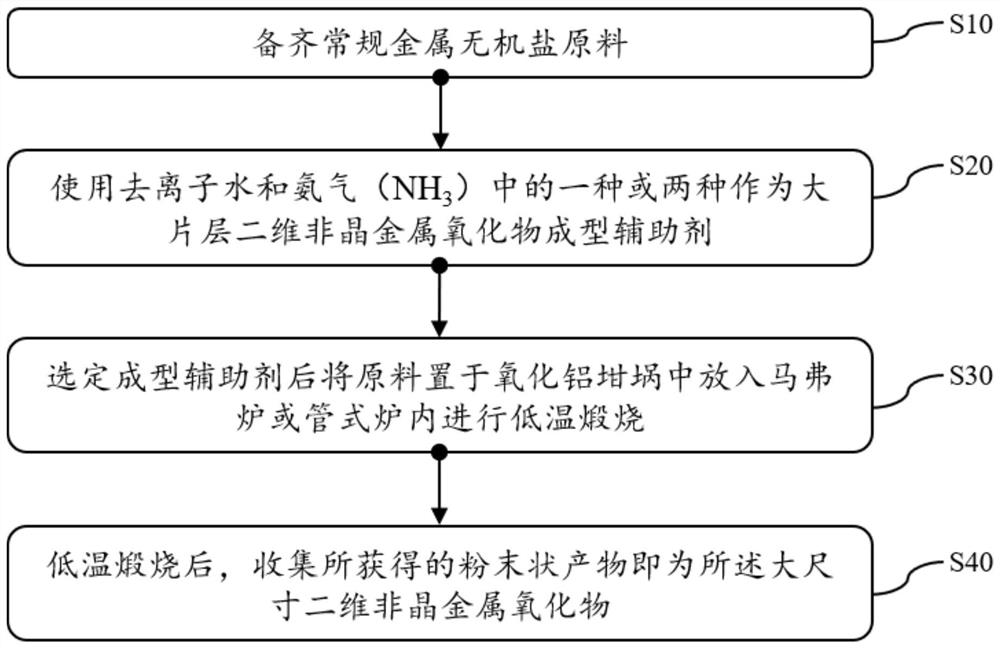

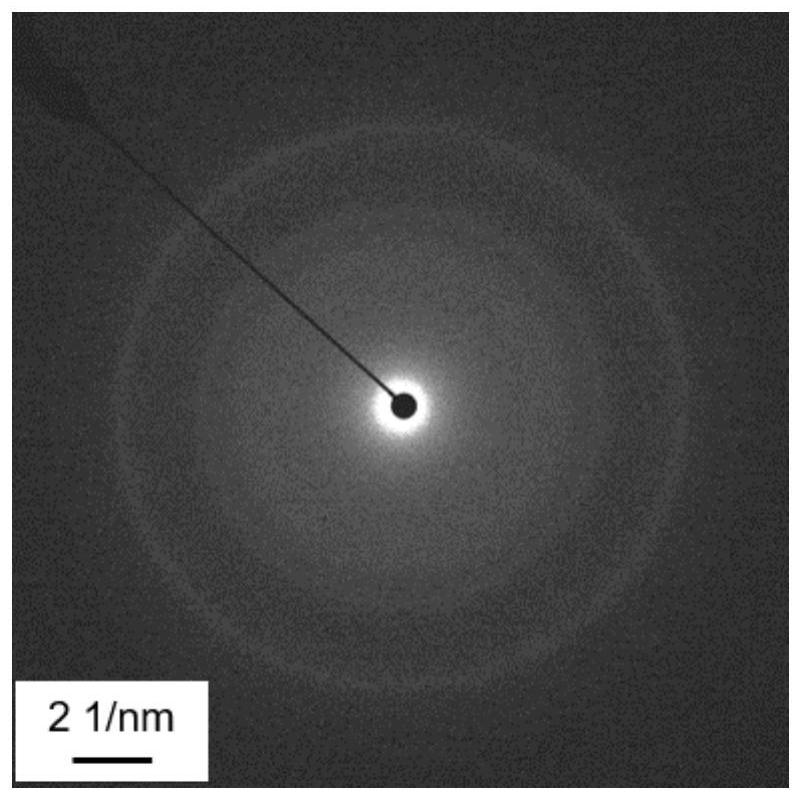

[0046] Example 1: A large-scale two-dimensional amorphous AlO x And preparation method thereof, comprises the steps:

[0047] (1), prepare Al (NO 3 ) 3 ·9H 2 O raw material;

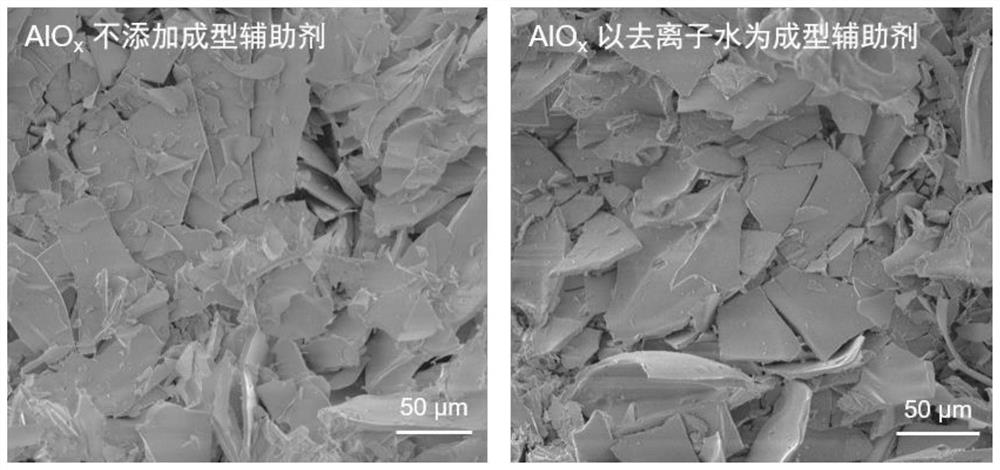

[0048] (2), using deionized water as a large lamella two-dimensional amorphous metal oxide forming auxiliary, and setting up a control experiment without adding deionized water forming auxiliary;

[0049] (3), according to Al (NO 3 ) 3 ·9H 2 The molar ratio between metal atoms in O and deionized water is 1:60 to prepare the mixture;

[0050] (4), the mixture material is gently stirred and placed in the alumina crucible and put into the muffle furnace to carry out low-temperature calcination, and the temperature in the muffle furnace is raised from room temperature to 800 ℃ with a temperature increase rate of 13 ℃ / min, and Keep warm for 90min;

[0051] (5), after calcination, the temperature in the muffle furnace is naturally cooled to room temperature, and the powdery product obtained by collect...

Embodiment 2

[0054] Embodiment 2: a large-size two-dimensional amorphous CrOx and a preparation method thereof, comprising the following steps:

[0055] (1), prepare Cr (NO 3 ) 3 ·9H 2 O raw material;

[0056] (2), the use of deionized water and deionized water and NH 3 As a large lamellar two-dimensional amorphous metal oxide forming aid, a control experiment without adding a forming aid was set at the same time;

[0057] (3) When deionized water is used as a molding aid, according to Cr(NO 3 ) 3 ·9H 2 The molar ratio between metal atoms in O and deionized water is 1:200 to prepare the mixture;

[0058] (4), with deionized water and NH 3 When used as a molding aid, deionized water is based on Cr (NO 3 ) 3 ·9H 2 The molar ratio between metal atoms in O and deionized water was 1:50 for addition, NH 3 The flux is related to the volume of the reaction chamber as follows:

[0059] Q=(10~30)·V

[0060] in:

[0061] Q stands for NH 3 Flux, in sccm;

[0062] V represents the volu...

Embodiment 3

[0068] Embodiment 3: a large-size two-dimensional amorphous ZrOx and preparation method thereof, comprising the following steps:

[0069] (1), prepare Zr (NO 3 ) 4 ·5H 2 O raw material;

[0070] (2), use deionized water and NH respectively 3As a large lamellar two-dimensional amorphous metal oxide forming aid, a control experiment without adding a forming aid was set at the same time;

[0071] (3) When deionized water is used as a molding aid, according to Zr (NO 3 ) 4 ·5H 2 The molar ratio between the metal atoms in O and deionized water was 1:75 to prepare the mixture; with NH 3 When used as a molding aid, NH 3 The flux is related to the volume of the reaction chamber as follows:

[0072] Q=(10~30)·V

[0073] in:

[0074] Q stands for NH 3 Flux, in sccm;

[0075] V represents the volume of the reaction chamber, in dm 3 or L.

[0076] The volume of the reaction chamber used in this experiment is 3.04L, and the corresponding NH can be determined from the above r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com