Sand blasting and paint spraying equipment for composite material colored artistic well lid and manufacturing process of sand blasting and paint spraying equipment

A composite material and painting equipment technology, which is applied in the direction of manufacturing tools, painting booths, abrasive jetting machine tools, etc., can solve problems such as inconvenient handling, blockage of sand collection ports, affecting spraying and debris collection operations, and achieves the goal of accelerating the drying rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

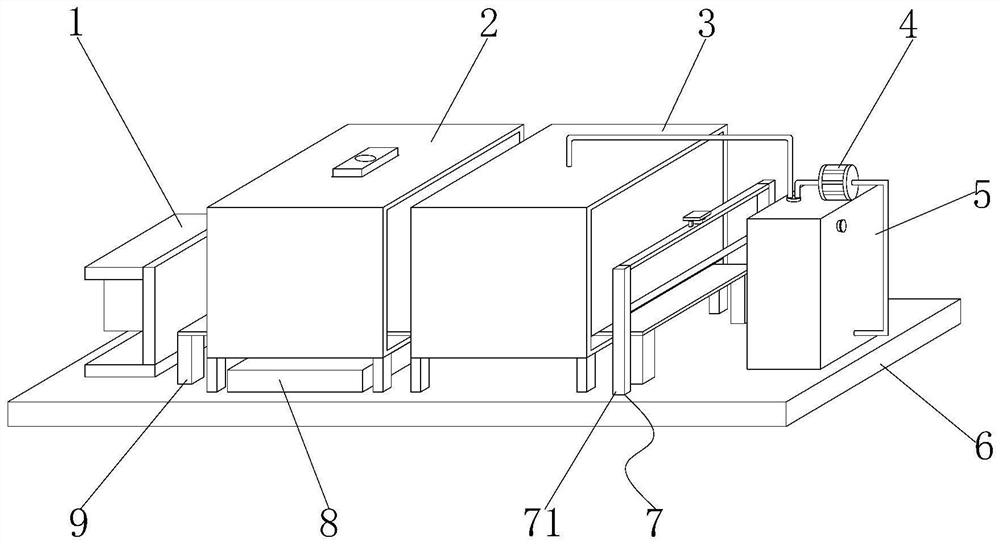

[0027] see Figure 1-6 , the present invention provides the following technical solutions: a kind of sandblasting and painting equipment for composite color art manhole covers, comprising a base 6, the upper end of the base 6 is connected with a sandblasting machine 1, and one side of the sandblasting machine 1 is provided with a roller 9, One end of the periphery of the drum machine 9 is provided with a sandblasting bin 2, a sand collecting port 11 is connected below the sandblasting bin 2, a storage box 8 is provided below the sand collecting port 11, and the other end of the periphery of the drum machine 9 is provided with a drying component 7 ;

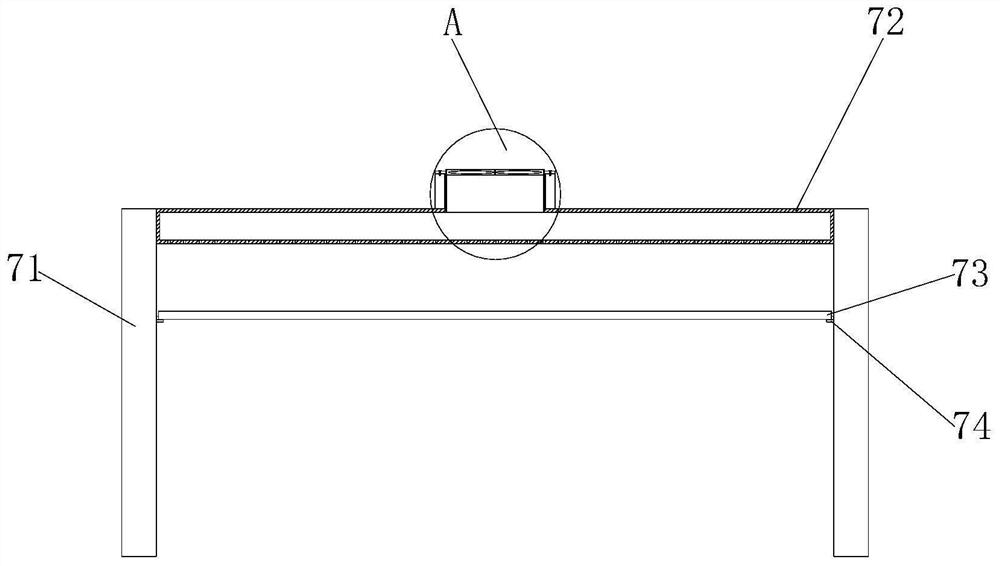

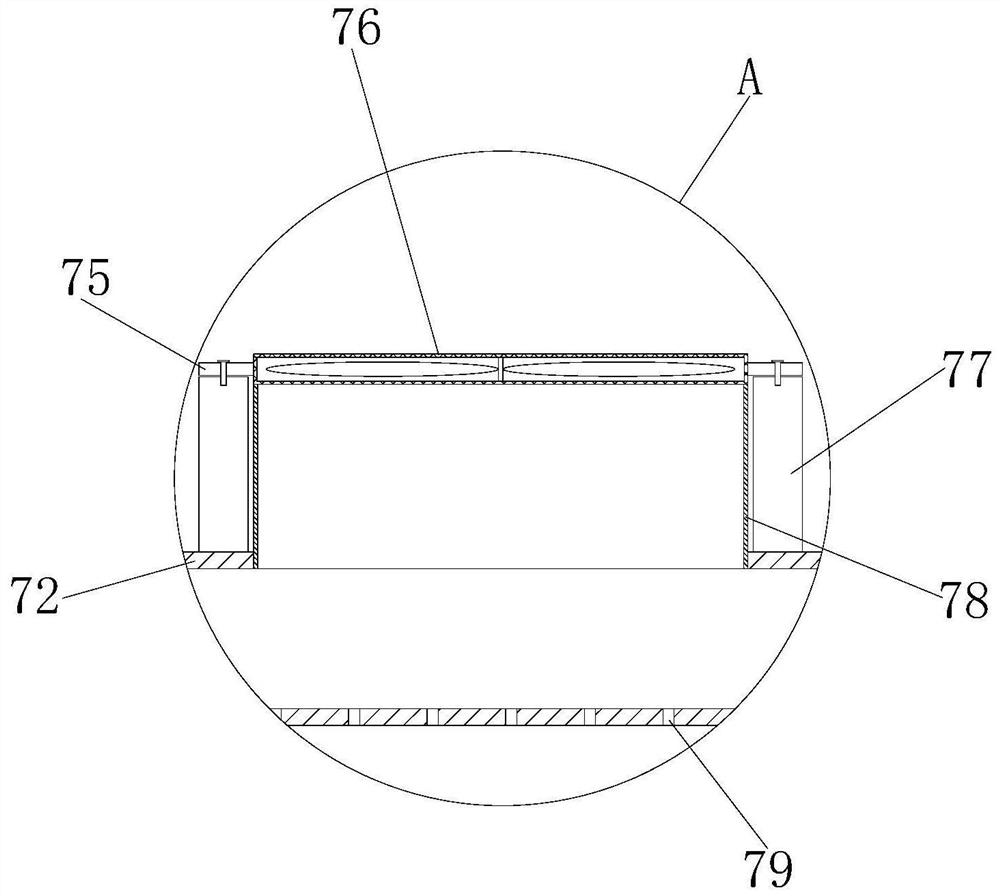

[0028] The drying assembly 7 includes a support rod 71, a hollow plate 72, a fan 76, an air guide hood 78 and an air outlet 79. A support rod 71 is connected on both sides of the top of the base 6 and at one end of the drum machine 9 away from the sandblasting chamber 2. A hollow plate 72 is connected between the two support rods...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that a rotating assembly 10 is provided inside the storage box 8 and at a position corresponding to the sand collecting port 11 , and the rotating assembly 10 includes a transmission rod 101 , a driving wheel 102 , a rotating rod 103 , and a driven wheel 104. The rotary motor 105 and the mounting plate 106, the inner side wall of the storage box 8 is connected with the mounting plate 106, the side of the mounting plate 106 away from the storage box 8 is connected with the rotary motor 105, and the output end of the rotary motor 105 is connected with the transmission rod 101 One end of the transmission rod 101 is connected with a driving wheel 102, and one end of the transmission rod 101 close to the driving wheel 102 is provided with a rotating rod 103, and a driven wheel 104 is connected on the outer side wall of the rotating rod 103 and at the position corresponding to the driving wheel 102,

[0036]Further in ...

Embodiment 3

[0040] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that a heat dissipation assembly 12 is provided on the side wall of the storage box 8 and at a position corresponding to the mounting plate 106 . The column 124 and the threaded hole 125, the side wall of the storage box 8 is provided with a mounting port 123, the interior of the mounting port 123 is provided with a heat sink 122, the heat sink 122 and the storage box 8 are connected by bolts, and the mounting port 123 and the mounting plate The side walls of 106 are provided with a number of threaded holes 125, and the interior of the corresponding two threaded holes 125 are threadedly connected with heat-conducting columns 124.

[0041] Further in the present invention, a dustproof net 121 is provided inside the installation port 123 and above the heat sink 122, and the dustproof net 121 and the storage box 8 are connected by bolts.

[0042] By adopting the above technical solution, impurities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com