Hollow nitrogen-doped carbon sphere supported metal catalyst as well as preparation method and application thereof

A metal-loaded, nitrogen-doped carbon technology, applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instruments and methods, can solve the problems of high catalyst consumption, long reaction time, low stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

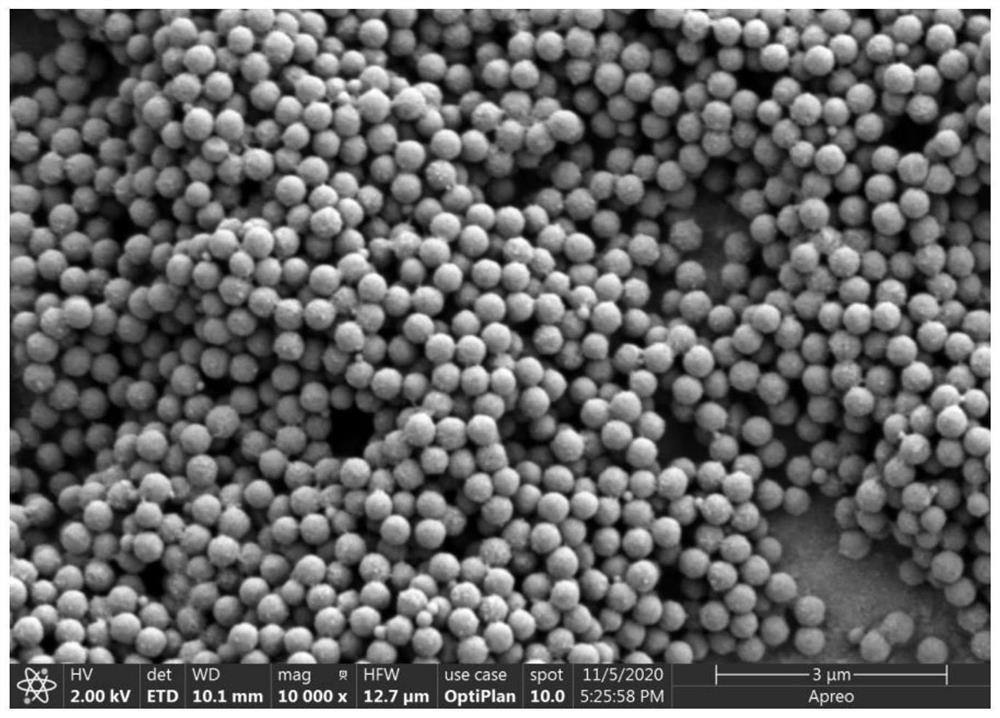

[0039] The embodiment of the present invention provides a preparation method of a catalyst applied to furfural reductive amination to prepare furfuryl amine. The preparation method includes the following processes: (1) preparation of a hard template; (2) carbon source and nitrogen source precursors in the hard The surface of the template is polymerized to form a composite; (3) metal precursor is added; (4) high temperature calcination. The steps of (3) and (4) can be reversed according to the sequence of loading the metal precursors.

[0040] The embodiment of the present invention provides a nitrogen-doped hollow carbon sphere-loaded noble metal-based nanocatalyst applied to furfural reductive amination to prepare furfurylamine, the specific steps of which include:

[0041] 1. Preparation of hard template:

[0042] Preparation of polystyrene hard template: 21 mL of styrene, 1.1 mL of methyl methacrylate, 0.92 mL of acrylic acid, and 0.49 g of ammonium bicarbonate were added ...

Embodiment 1

[0064] Direct synthesis, preparation of Ru@NHCS-1-500-3 catalyst

[0065] Add 0.1g of hard template (polystyrene nanospheres) to 50mL of deionized water, after sonicating for 30min, put it into an oil bath and stir, after stirring for 30min, add 0.1g of dopamine (add multiple times), add 17.6mg RuCl 3 , after stirring for 30 min, 0.30285 g of trisaminomethane and 61.5 microliters of concentrated hydrochloric acid were added, and the pH value of the entire mixed system was 8.5. After stirring for 22 h, it was centrifuged and washed, and then placed in a refrigerator for freezing, followed by freeze-drying. The frozen samples were ground into powder and then roasted in a mixture of nitrogen and hydrogen. The firing temperature was 500 °C, the heating rate was 10 °C / min, and the holding time was 2 h. After the roasting, nitrogen-doped hollow carbon was obtained. Ball-supported Ru nanocatalysts.

Embodiment 2

[0067] Direct synthesis, preparation of Ru@NHCS-1-600-3 catalyst

[0068] Add 0.1 g of hard template (polystyrene beads) into 50 mL of deionized water, and after sonicating for 30 min, put it into an oil bath and stir, after stirring for 30 min, add 0.1 g of dopamine (multiple additions), add 17.6 g of dopamine mg RuCl 3 , after stirring for 30 min, 0.30285 g of trisaminomethane and 61.5 microliters of concentrated hydrochloric acid were added, and the pH value of the entire mixed system was 8.5. After stirring for 22 h, it was centrifuged and washed, and then placed in a refrigerator for freezing, followed by freeze-drying. The frozen samples were ground into powder and then roasted in a mixture of nitrogen and hydrogen. The firing temperature was 600 °C, the heating rate was 10 °C / min, and the holding time was 2 h. After the roasting, nitrogen-doped hollow carbon was obtained. Ball-supported Ru nanocatalysts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com