Double gel capable of printing protein network as well as preparation method and application of double gel

A double gel and network technology, which is applied in the field of printable protein network double gel and its preparation, can solve the problems of oil-in-water double gel that have not been reported, and achieve excellent printing properties, good rheological properties, The effect of high printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Accurately weigh a certain amount of rice bran protein, locust bean gum and carrageenan, and dissolve them in a phosphate buffer solution with a pH of 5.0 to prepare: the mass concentration of rice bran protein is 1%, and the mass concentration of carrageenan and locust bean gum are both 0.75%. The mixed solution was added with rapeseed oil with a mass concentration of 15% beeswax at a water-oil volume ratio of 1:3, and then the system was emulsified by shearing for 4min at a shearing speed of 9000rmp under a water bath of 70°C using a shear emulsifier. , and cooled for 24 hours to make the system fully gel to obtain double gel.

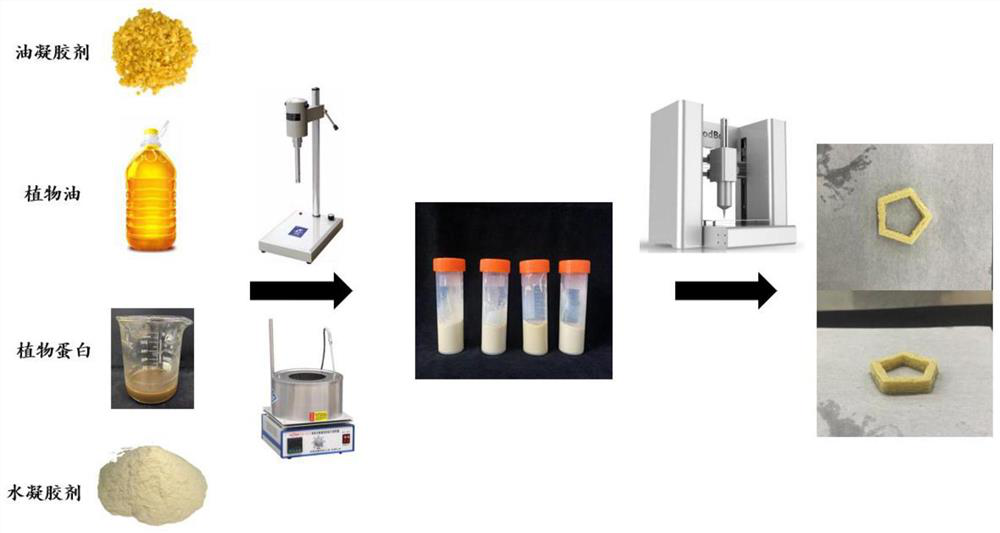

[0040] like figure 1 shown, figure 1 The preparation process of the present invention is described. First, the protein and the hydrogel agent are mixed to prepare a mixed solution, which is mixed with the vegetable oil containing the gel agent under the condition of a water bath for high-speed shearing (thermal preparation method). Due to the...

Embodiment 2

[0042] Accurately weigh a certain amount of rice bran protein and konjac gum, dissolve it in a phosphate buffer solution with a pH of 5.0 to prepare a mixed solution with a protein concentration and a mass concentration of konjac gum of 1.5%, and add a water-oil volume ratio of 1:3 with a mass concentration of 1.5%. It is rapeseed oil with 10% beeswax, and then the system is emulsified by shearing emulsifier at a shear rate of 9000rmp for 4min under a water bath of 80°C, and cooled for 24 hours to make the system fully gel to obtain a double gel.

Embodiment 3

[0044] Accurately weigh a certain amount of peanut protein and flaxseed gum, dissolve it in a phosphate buffer solution with a pH of 7.0 to prepare a mixed solution with a protein concentration of 1% and a mass concentration of flaxseed gum. The peanut oil with a mass concentration of 4% monoglyceride was then emulsified by shearing at a shear rate of 9000 rmp for 4 min under a 70°C water bath with a shear emulsifier, and cooled for 24 hours to fully gel to obtain a double gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com