Long-circulation lithium ion battery

A lithium-ion battery, long-cycle technology, applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of easy peeling off of graphite layers, degradation of lithium-ion battery cycle performance, etc., to reduce the occurrence of solvation co-embedding, inhibit Formation of Li+- solvent structure, effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

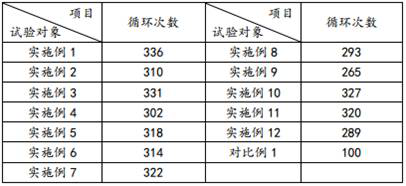

Examples

preparation example 1

[0030] Preparation Example 1, a negative electrode material, weighed D50 as 17 ± 2 microns, ratio table 2.5 ± 0.5 m 2 / g, 1kg of natural graphite with a deduction capacity of ≥360mAh / g, added to the ball mill, and then weighed 0.03kg of Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 (lithium superion conductor). Using small balls with a diameter of 5 mm and a ball-to-material ratio of 10:1, ball milled at a speed of 300 r / min for 2 hours to obtain natural graphite coated with fast ion conductors, and the coating thickness of the fast ion conductors is 100 nm.

preparation example 2

[0031] Preparation Example 2, a negative electrode material, weighed D50 as 17 ± 2 microns, ratio table 2.5 ± 0.5m 2 / g, 1kg of natural graphite with a deduction capacity of ≥360mAh / g, added to the ball mill, and then weighed 0.1kg of Li 7-x La 3+x Zr 2 O 12 (0.5≥x≥0.1) (garnet type ionic conductor). Using small balls with a diameter of 8 mm and a ball-to-material ratio of 15:1, ball milled at a speed of 400 r / min for 2 hours to obtain natural graphite coated with fast ion conductors, and the coating thickness of the fast ion conductors is 300 nm.

preparation example 3

[0032] Preparation Example 3, a negative electrode material, weighed D50 as 17 ± 2 microns, 2.5 ± 0.5 m from the table 2 / g, 1kg of natural graphite with a deduction capacity of ≥360mAh / g, added to the ball mill, and then weighed 0.05kg of Li 3x La 2 / 3-x TiO 3 (0.5≥x≥0.1) (perovskite lithium lanthanum titanate). Using small balls with a diameter of 5 mm and a ball-to-material ratio of 10:1, ball milled at a speed of 260 r / min for 3 hours to obtain natural graphite coated with fast ion conductors, and the coating thickness of the fast ion conductors is 150 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com