Porous current collector and preparation method thereof

A technology of porous current collectors and metal substrates, applied in electrode manufacturing, electrode carriers/current collectors, electrical components, etc., can solve the problems of difficult control of hole size, influence on current collector performance, easy to tear metal foil, etc., to achieve Effect of improving surface wetting tension, low cost, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A preparation method of a porous current collector provided by the present application comprises the following steps:

[0041] S1. Provide metal base material;

[0042] The metal substrate of the present application is aluminum foil or copper foil, but is not limited thereto. In the present application, the thickness of the metal substrate is preferably 10 to 20 μm. In other embodiments of the present application, the thickness of the metal substrate may also be less than 10 μm or greater than 20 μm.

[0043] S2, convey the metal substrate to the extrusion roller for extrusion;

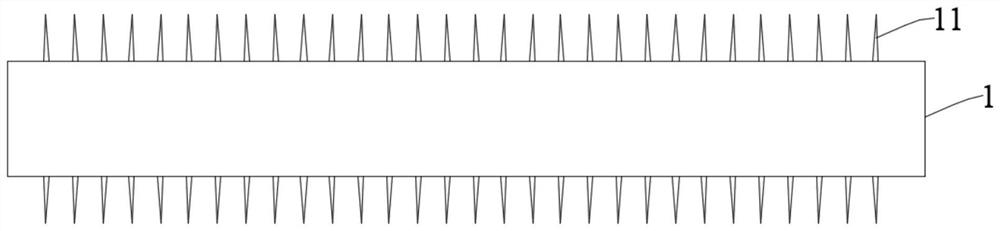

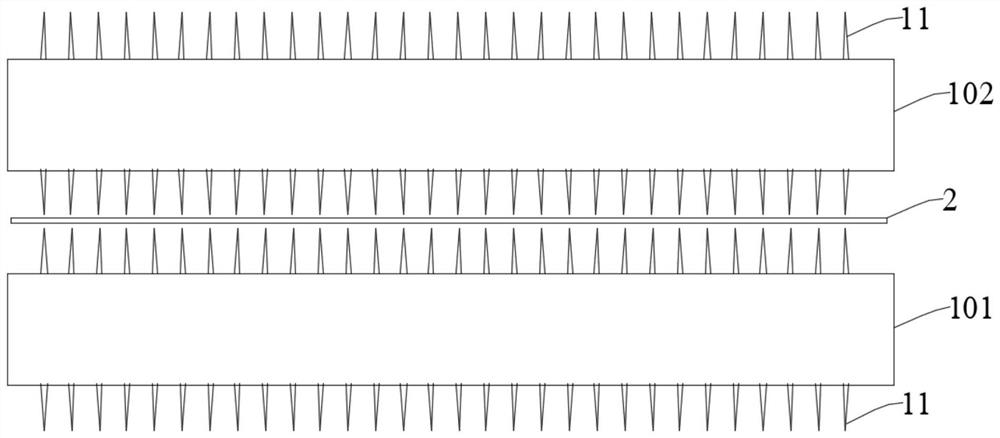

[0044] see figure 1 , the surface of the squeeze roller 1 of the present application is provided with a puncture needle 11, and the puncture needle 11 of the present application is used to pierce the metal substrate, so as to cause perforation or mechanical damage to the metal substrate.

[0045] Because the thickness of the metal substrate is very thin, after the rolled metal substrate is ...

Embodiment 1

[0067] A preparation method of a porous current collector, comprising the following steps:

[0068] S1. Provide a copper foil substrate with a thickness of 15 μm;

[0069] S2. The copper foil base material is transported to a squeezing roll for squeezing, and the squeezing roll is divided into a first squeezing roll and a second squeezing roll, wherein the first squeezing roll and the second squeezing roll are arranged in parallel, The metal substrate is transported between the first squeezing roller and the second squeezing roller for puncture treatment, and the surface of the squeezing roller is provided with a thorn with a diameter of 15 μm and a length of 16 μm;

[0070] S3. The extruded copper foil substrate is transported to a cleaning tank with a length of 1 m at a speed of 50 m / min. The cleaning tank contains an etching solution, and the etching solution includes 4 mol / L HCl and 0.6 mol / L Al2 ( SO4)3;

[0071] S4, drying the etched copper foil substrate at a drying t...

Embodiment 2

[0073] A preparation method of a porous current collector, comprising the following steps:

[0074] S1. Provide an aluminum foil substrate with a thickness of 20 μm;

[0075] S2. The aluminum foil base material is conveyed to the extrusion roller for extrusion, and the extrusion roller is divided into a first extrusion roller and a second extrusion roller, wherein the first extrusion roller and the second extrusion roller are arranged in parallel, and the metal The substrate is transported between the first squeezing roller and the second squeezing roller for puncture treatment, and the surface of the squeezing roller is provided with a needle with a diameter of 20 μm and a length of 22 μm;

[0076] S3. The extruded aluminum foil substrate is sequentially transported to the pickling tank, the alkaline cleaning tank and the etching tank, all of which are 1 m long, at a speed of 60 m / min. The pickling solution in the pickling tank includes HF and H 2 SO 4 , HF and H 2 SO 4 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com