Flexible conductive polyurethane fiber and preparation method thereof

A polyurethane fiber, flexible and conductive technology, applied in fiber processing, fiber chemical characteristics, stretch spinning and other directions, can solve the problems of loss of conductivity, loss, conductive particles easily fall off conductivity, etc., to improve the degree of curl, cortex structure Stable, well-aligned effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

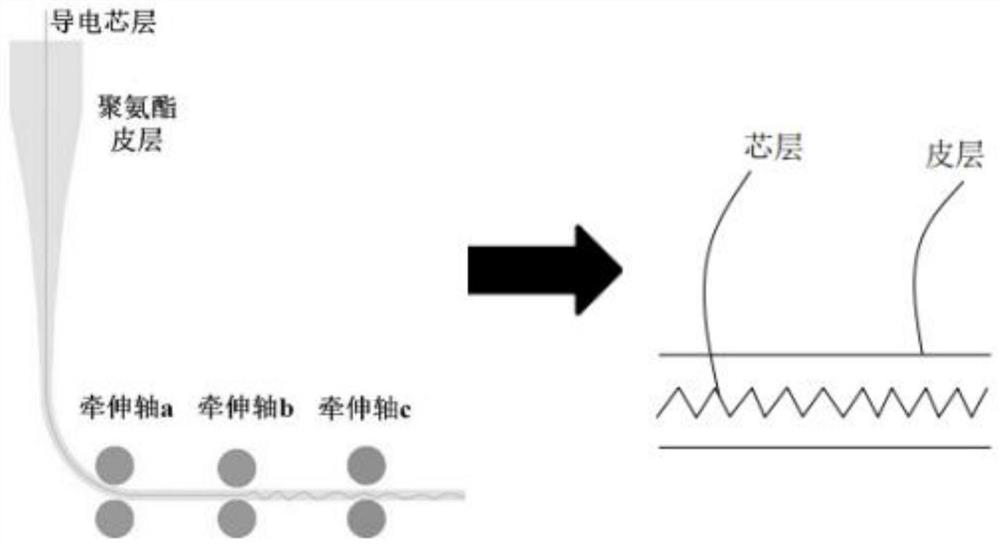

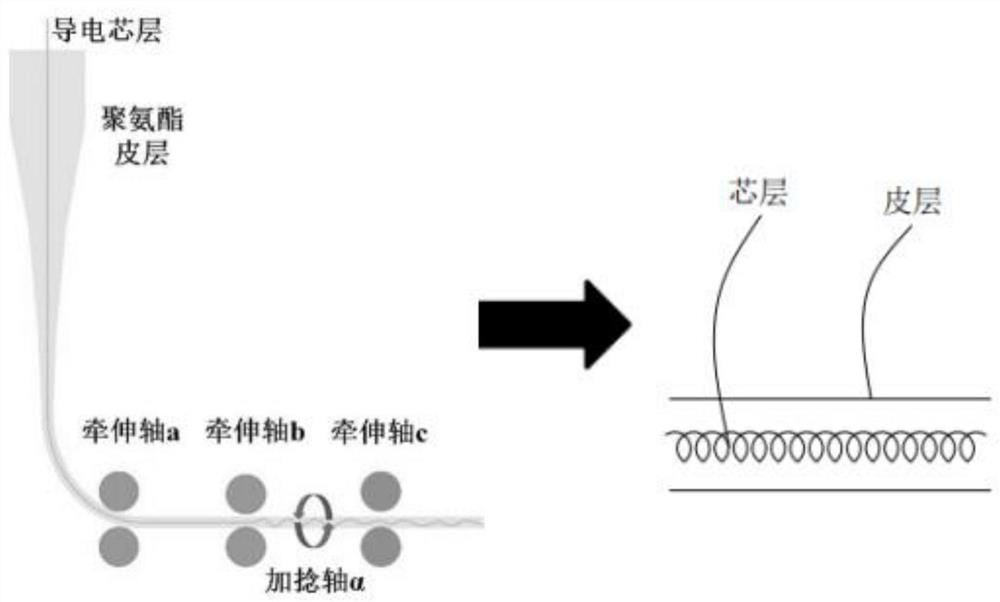

[0031] like figure 1 and figure 2 As shown, the present invention also provides a preparation method of the above-mentioned flexible conductive polyurethane fiber, comprising the following steps:

[0032] S1. Preparation of spinning dope:

[0033]Stir the polar solvent, and then add the polyurethane resin to the polar solvent according to the mass ratio of the polyurethane resin and the polar solvent as (20%-45%): (55%-80%), at 20-30 ° C mechanically Stirring for 100-140min, after the polyurethane resin is completely dissolved and the spinning solution is a homogeneous solution, the obtained solution is subjected to vacuum defoaming treatment at a temperature of 20-30°C to obtain a spinning solution.

[0034] Wherein, the polar solvent includes one or more of tetrahydrofuran, N,N, dimethylformamide, and N,N, dimethylacetamide.

[0035] S2. Preparation of flexible conductive polyurethane fibers:

[0036] (1) Preparation of two-dimensional flexible conductive polyurethane f...

Embodiment 1

[0048] A preparation method of flexible conductive polyurethane fiber, comprising the following steps:

[0049] S1. Preparation of spinning dope:

[0050] Stir the tetrahydrofuran, then add 30 g of the polyurethane resin to 70 g of the tetrahydrofuran solvent according to the mass ratio of the polyurethane resin and the tetrahydrofuran as 30%: 70%, and stir mechanically for 120 min at 25 ° C until the polyurethane resin is completely dissolved and the spinning solution is a homogeneous phase After the solution was obtained, the obtained solution was subjected to vacuum defoaming treatment at a temperature of 25 °C to obtain a spinning solution.

[0051] S2. Preparation of Flexible Conductive Polyurethane Fibers (2D):

[0052] Spinning was carried out by using a coaxial spinning nozzle, the nickel wire with a diameter of 10 μm was introduced into the core layer tunnel I, the spinning dope obtained in step S1 was loaded into the cortex tunnel II, and the nickel wire in the core...

Embodiment 2-5

[0055] A preparation method of flexible conductive polyurethane fiber, compared with Example 1, the difference is that in step S2, the drafting speed of the drafting axis a, the drafting axis b and the drafting axis c are different. Example 1 is roughly the same and will not be repeated here.

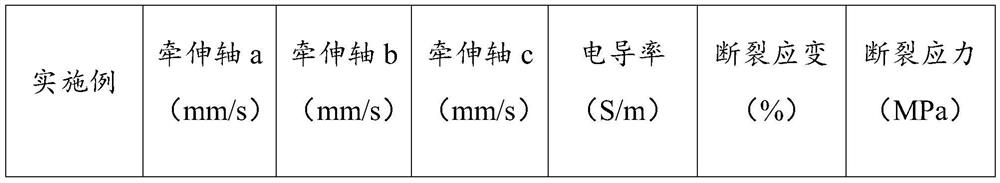

[0056] The preparation method of the flexible conductive polyurethane fibers (two-dimensional) prepared in Examples 1-5 was tested for performance. The results are shown in Table 1. The electrical conductivity refers to the electrical conductivity when the fiber is stretched by 1000%:

[0057] Table 1 Relevant properties of flexible conductive polyurethane fibers prepared in Examples 1-5

[0058]

[0059]

[0060] It can be seen from Table 1 that when the drafting speed of the drafting axis a and the drafting axis c is constant, as the drafting speed of the drafting axis b decreases (Examples 1, 2, 3, that is, as the drafting speed decreases With the increase of the ratio of draf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com