Method for preparing polypeptide by utilizing eggshell membrane, polypeptide prepared by method and application of polypeptide

An eggshell film and facial mask technology, applied in the field of peptides and applications, can solve the problems of low efficiency and time-consuming enzymatic hydrolysis, and achieve the effects of high efficiency, easy skin absorption, and small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also provides the preparation method of the above-mentioned facial mask, is characterized in that, comprises the steps:

[0054] S11, prepare each component according to the mass percentage;

[0055] S12, take the poloxamer 407 and part of the water to configure the poloxamer 407 aqueous solution, take the polyvinyl alcohol and the remaining water to configure the polyvinyl alcohol solution, and mix the poloxamer 407 aqueous solution and the polyvinyl alcohol solution in the Mix uniformly at 1-6° C., then add the glycerin and mix uniformly, and then add the polypeptide and mix uniformly to obtain the facial mask.

[0056] Based on the preparation method of the mask according to the embodiment of the present invention, the preparation process of the Poloxamer 407 aqueous solution is as follows: after mixing the Poloxamer 407 with the part of the water evenly, it is placed at 1-6° C. overnight to fully swell .

[0057] Based on the preparation meth...

Embodiment 1

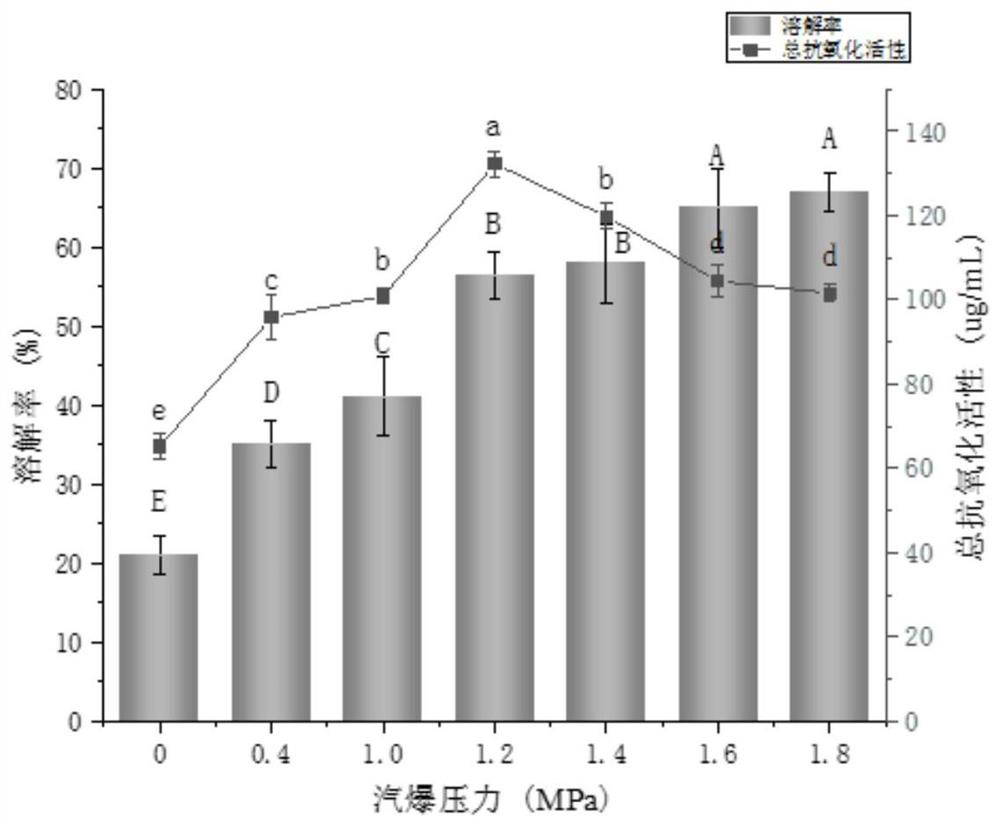

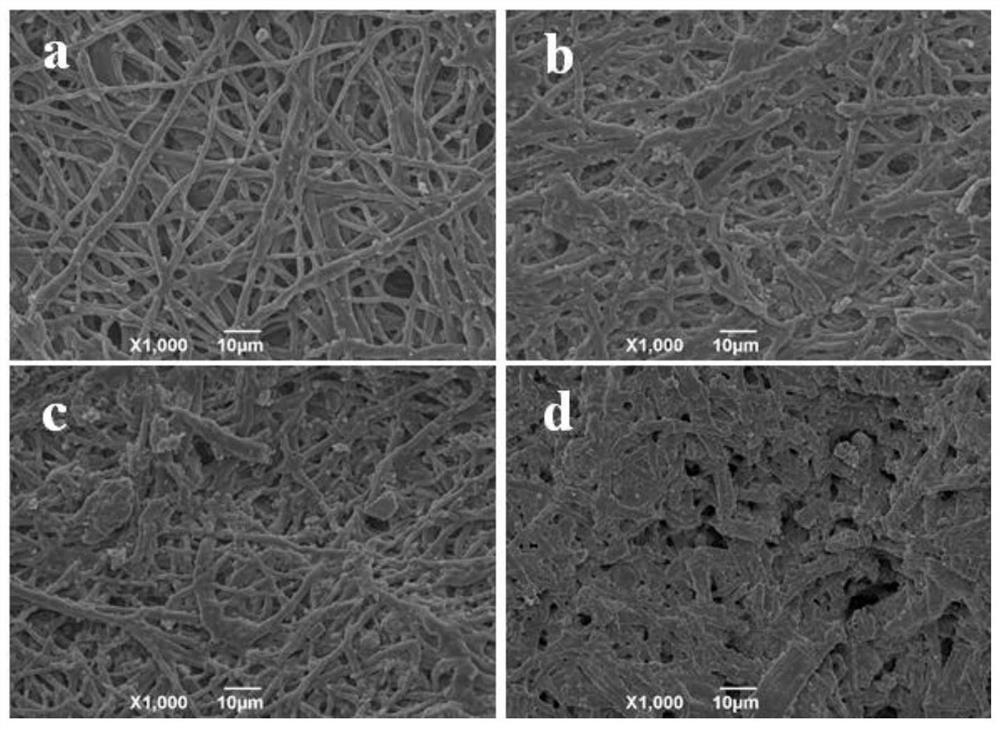

[0059] (1) take by weighing 300 grams of eggshell membranes and place them in the steam explosion machine reactor, and under the pressure of 1.2MPa, hold the pressure for 3min, then release the pressure instantly, collect the steam explosion samples, and store at -20 ℃ for subsequent use;

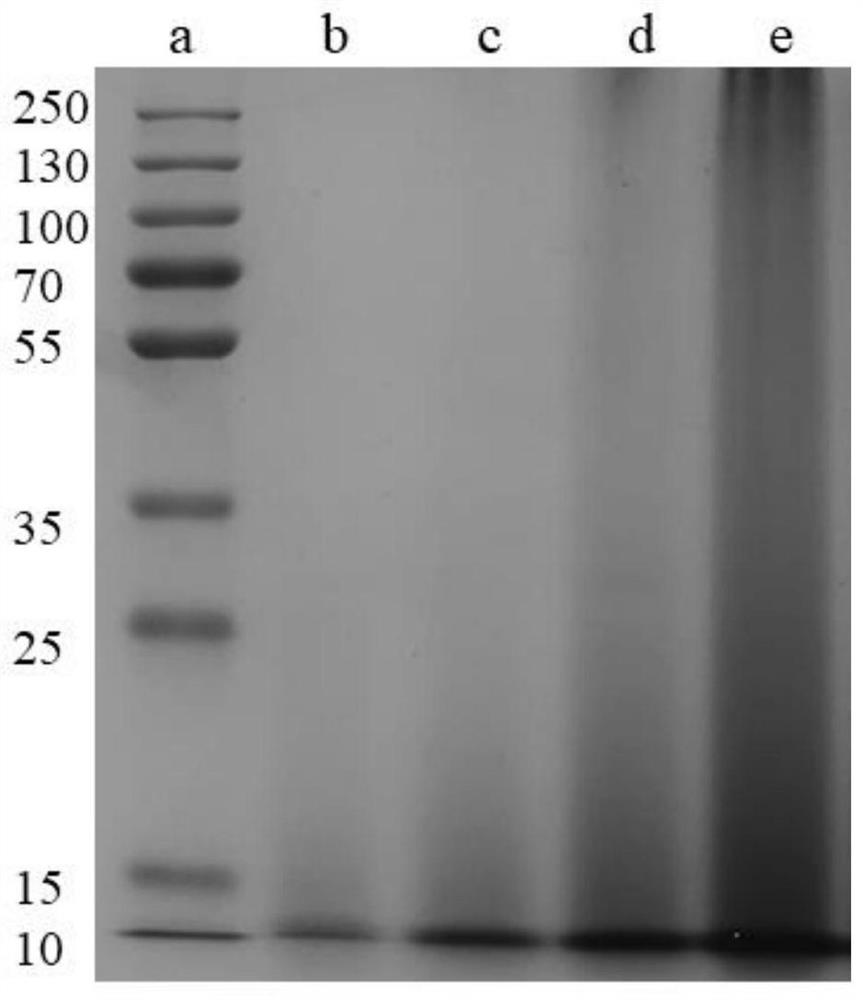

[0060] (2) Weigh 3 grams of eggshell membranes processed by steam explosion in a 100mL conical flask, add 60mL of an aqueous sodium hydroxide solution with a pH of 8.5 at a material-to-liquid ratio of 1:20, add an enzyme amount of 6000U / g Alkaline protease was used for enzymatic hydrolysis. The enzymatic hydrolysis time was 5 h, and the enzymatic hydrolysis temperature was 56 °C. After the enzymatic hydrolysis reaction, the enzyme was inactivated at 90 °C for 10 min. The enzymatic hydrolysis solution was filtered, and the filtrate was centrifuged at 8000 rpm for 10 min. The shell membrane polypeptide product was obtained by drying and stored at -20°C for later use.

[0061] (3) Prepare an a...

Embodiment 2

[0064] (1) take by weighing 300 grams of eggshell membranes and place them in the reactor of a steam explosion machine, under the pressure of 1.4MPa, hold the pressure for 3min, then release the pressure instantaneously, collect the steam explosion samples, and store at -20 ℃ for subsequent use;

[0065] (2) Weigh 3 grams of eggshell membranes treated by steam explosion in a 100mL conical flask, add 60mL of an aqueous sodium hydroxide solution with a pH of 7 at a material-to-liquid ratio of 1:30, add an enzyme amount of 2000U / g Alkaline protease was used for enzymatic hydrolysis. The enzymatic hydrolysis time was 2 h, and the enzymatic hydrolysis temperature was 35 °C. After the enzymatic hydrolysis reaction was completed, the enzyme was inactivated at 90 °C for 10 min. The shell membrane polypeptide product was obtained by drying and stored at -20°C for later use.

[0066] (3) First, prepare the poloxamer 407 aqueous solution with a mass fraction of 14%, place it in a refrige...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com