Method for improving thermal performance of eutectic hydrated salt phase change material and modified product of eutectic hydrated salt phase change material

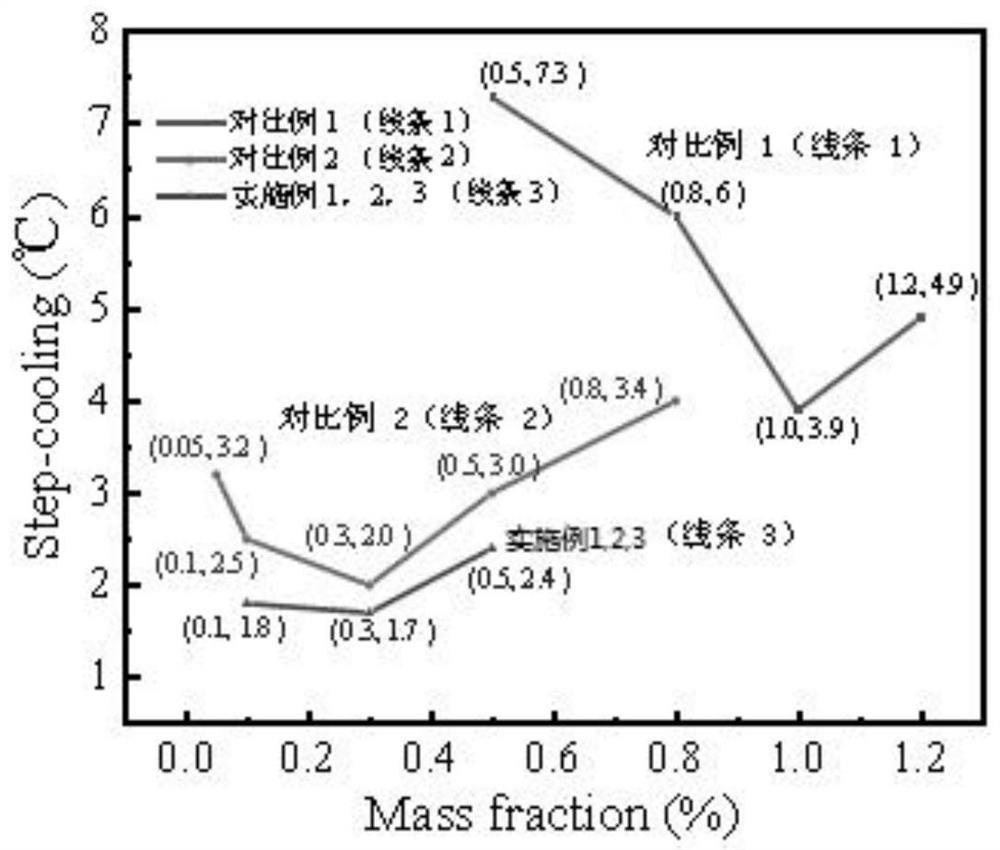

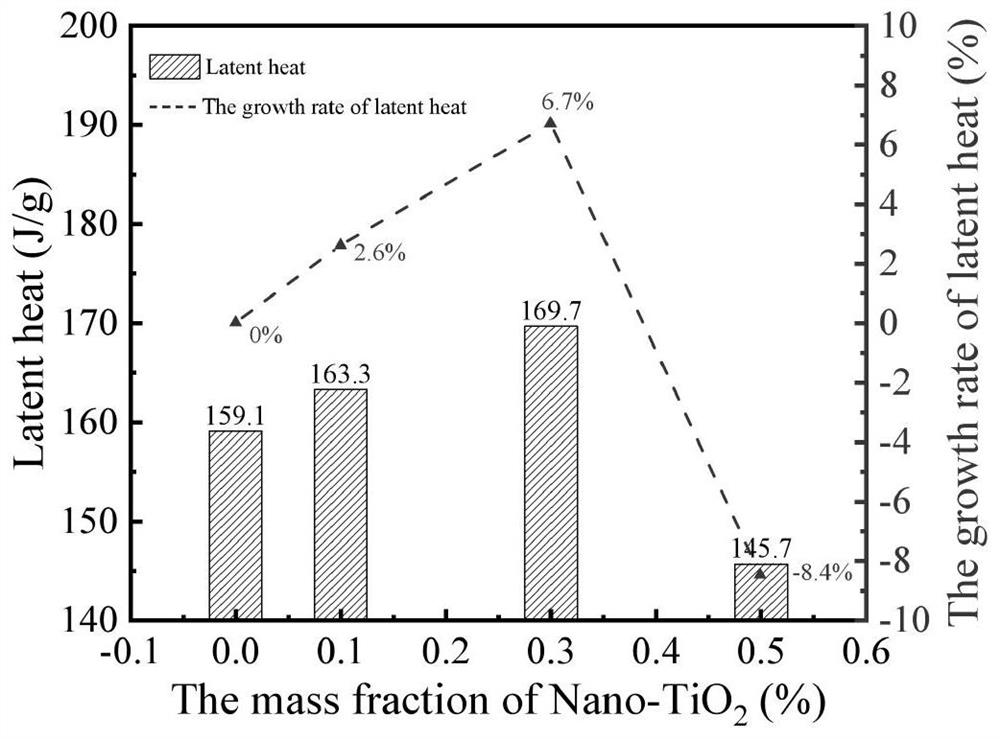

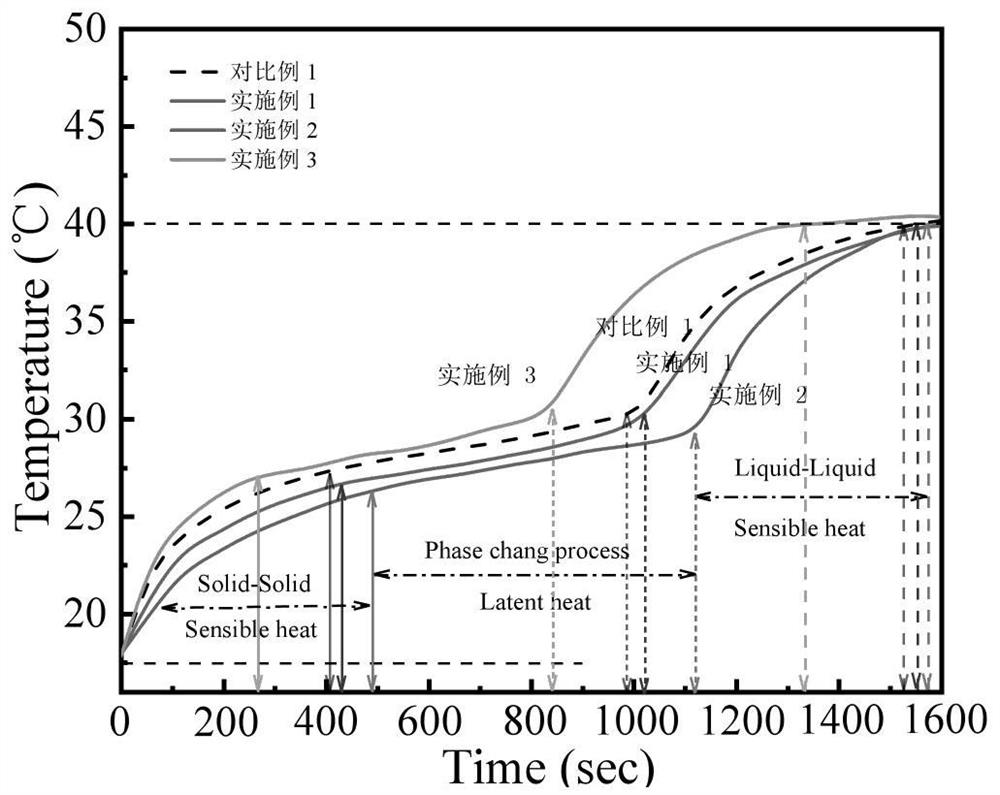

A technology of eutectic hydration and thermal performance, applied in the field of material chemistry, can solve the problems of latent heat and high degree of supercooling of hydrated salt phase change materials of phase separation and phase separation, achieve high heat storage density, low degree of supercooling, and improve thermal performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the modified eutectic hydrated salt phase change material in the embodiment is:

[0048] Step 1, mixing magnesium chloride hexahydrate and calcium chloride hexahydrate, heating to melting under the condition of 40~70 ℃, stirring evenly, to obtain calcium chloride hexahydrate / magnesium chloride hexahydrate eutectic hydrated salt solution;

[0049] Step 2, adding a nucleating agent and a thickening agent to the eutectic hydrated salt solution obtained in step 1 in turn under stirring conditions, and continuing to heat at a temperature of 40 to 70 ° C until complete dissolution, to obtain a preliminary modified eutectic hydration salt solution. salt solution;

[0050] Step 3: Add nano-modifier to the preliminary modified eutectic hydrated salt solution obtained in step 2, and ultrasonically disperse for 60-90 min under the condition of heating at 40-70 °C to obtain a further modified eutectic hydrated salt solution ;

[0051] Step 4: Add stabili...

Embodiment 1

[0053] Step 1: Mix 10 parts of magnesium chloride hexahydrate and 90 parts of calcium chloride hexahydrate powder, put it in a beaker, and put it into a water bath to heat and dissolve at 50 °C, and use a magnetic stirring rotor to stir the solution until it becomes clear solution to obtain calcium chloride hexahydrate / magnesium chloride hexahydrate eutectic hydrated salt solution;

[0054] Step 2: adding 1wt% of strontium chloride hexahydrate and 0.3wt% of calcium chloride hexahydrate / magnesium chloride hexahydrate eutectic hydrated salt solution to the eutectic hydrated salt solution prepared in step 1 in turn under stirring conditions; hydroxymethyl cellulose, continue to be heated at 50°C until completely dissolved to obtain a preliminary modified eutectic hydrated salt solution;

[0055] Step 3: Add nano-titanium dioxide with a mass of 0.1 wt% of the calcium chloride hexahydrate / magnesium chloride hexahydrate eutectic hydrated salt solution to the preliminary modified eut...

Embodiment 2

[0058] Step 1: Mix 10 parts of magnesium chloride hexahydrate and 90 parts of calcium chloride hexahydrate powder, put it in a beaker, and put it into a water bath to heat and dissolve at 50 °C, and use a magnetic stirring rotor to stir the solution until it becomes clear solution to obtain calcium chloride hexahydrate / magnesium chloride hexahydrate eutectic hydrated salt solution;

[0059] Step 2: adding 1wt% of strontium chloride hexahydrate and 0.3wt% of calcium chloride hexahydrate / magnesium chloride hexahydrate eutectic hydrated salt solution to the eutectic hydrated salt solution prepared in step 1 in turn under stirring conditions; hydroxymethyl cellulose, continue to be heated at 50°C until completely dissolved to obtain a preliminary modified eutectic hydrated salt solution;

[0060] Step 3: Add nano-titanium dioxide with a mass of 0.3 wt% of the calcium chloride hexahydrate / magnesium chloride hexahydrate eutectic hydrated salt solution to the preliminary modified eut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com